Combined type wall framework

A combination and wall technology, applied in the direction of walls, building components, columns, etc., can solve the problems affecting the thermal insulation effect of houses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

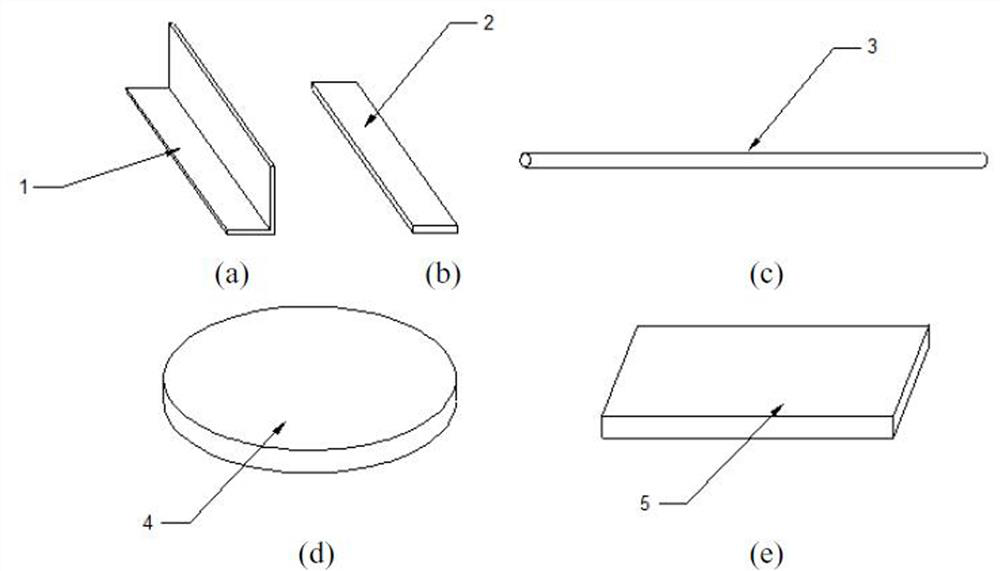

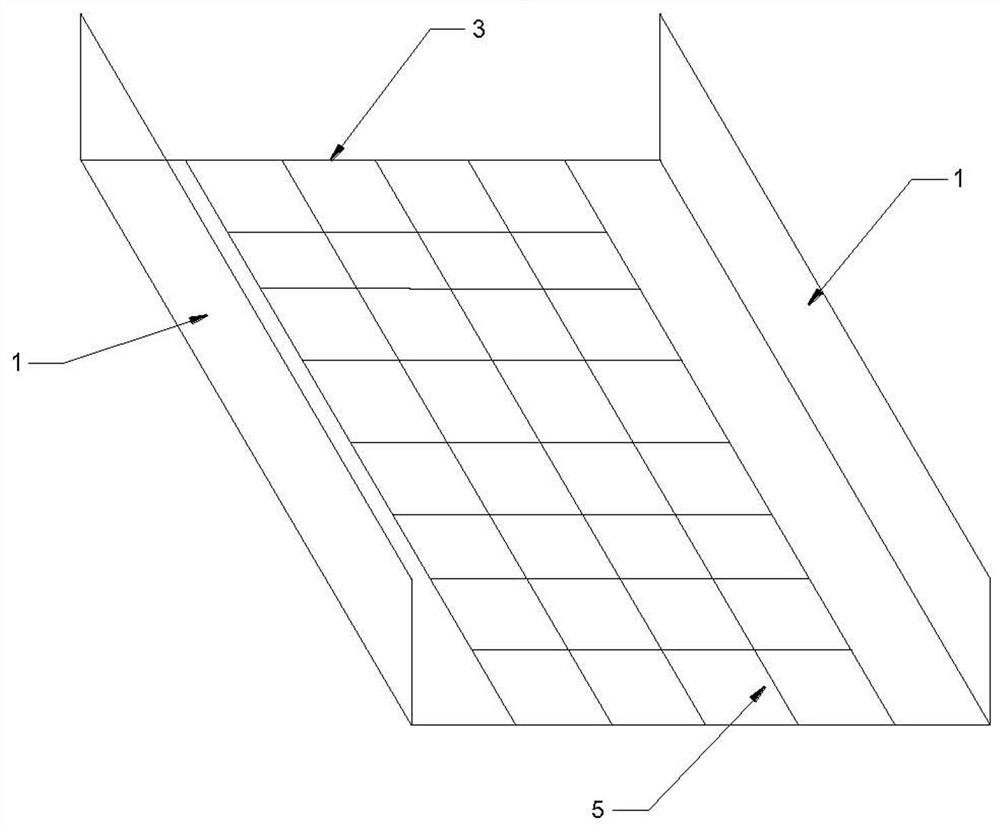

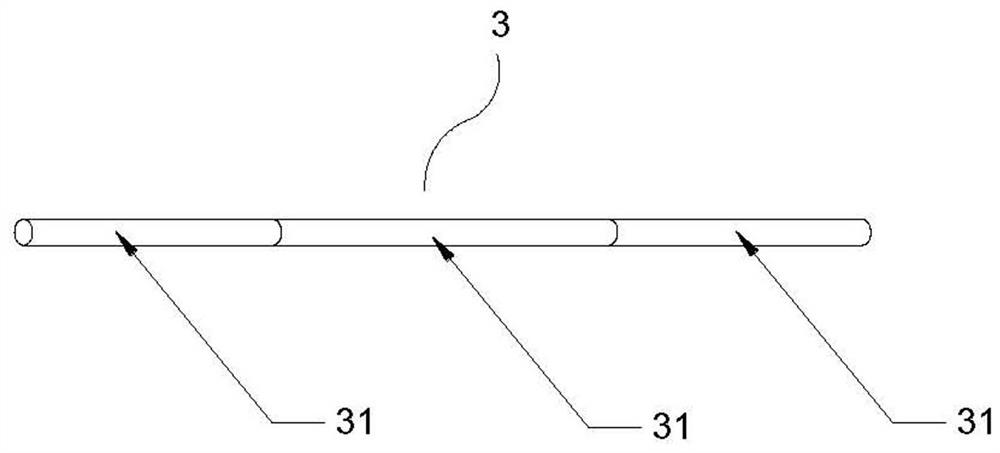

[0026] The combined wall frame formed in Example 1 uses reinforced keels to replace part of the light steel keels in the traditional wall frame, that is, the connecting pieces between any two adjacent light steel keels are replaced with steel keels, so as to block light Direct contact between steel keels. In this example, the specific structure of the composite wall skeleton is to use rod-shaped steel bars to connect two angled light steel bars. Since the thermal conductivity of the steel keel is much smaller than that of the light steel keel, the combined wall frame formed in this example can effectively block the heat conduction between the light steel keels and avoid the thermal bridge phenomenon of the combined wall frame. The wall constructed by the combined wall skeleton of this example has low energy consumption and no thermal bridge, which meets the requirements of new houses with thermal insulation effect, high indoor comfort, and no active heating and cooling technol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com