Drop test machine with function of preventing secondary impact

A secondary impact and testing machine technology, applied in impact testing, machine/structural component testing, measuring devices, etc., can solve problems such as secondary impact, rebound products, and low test accuracy, to ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

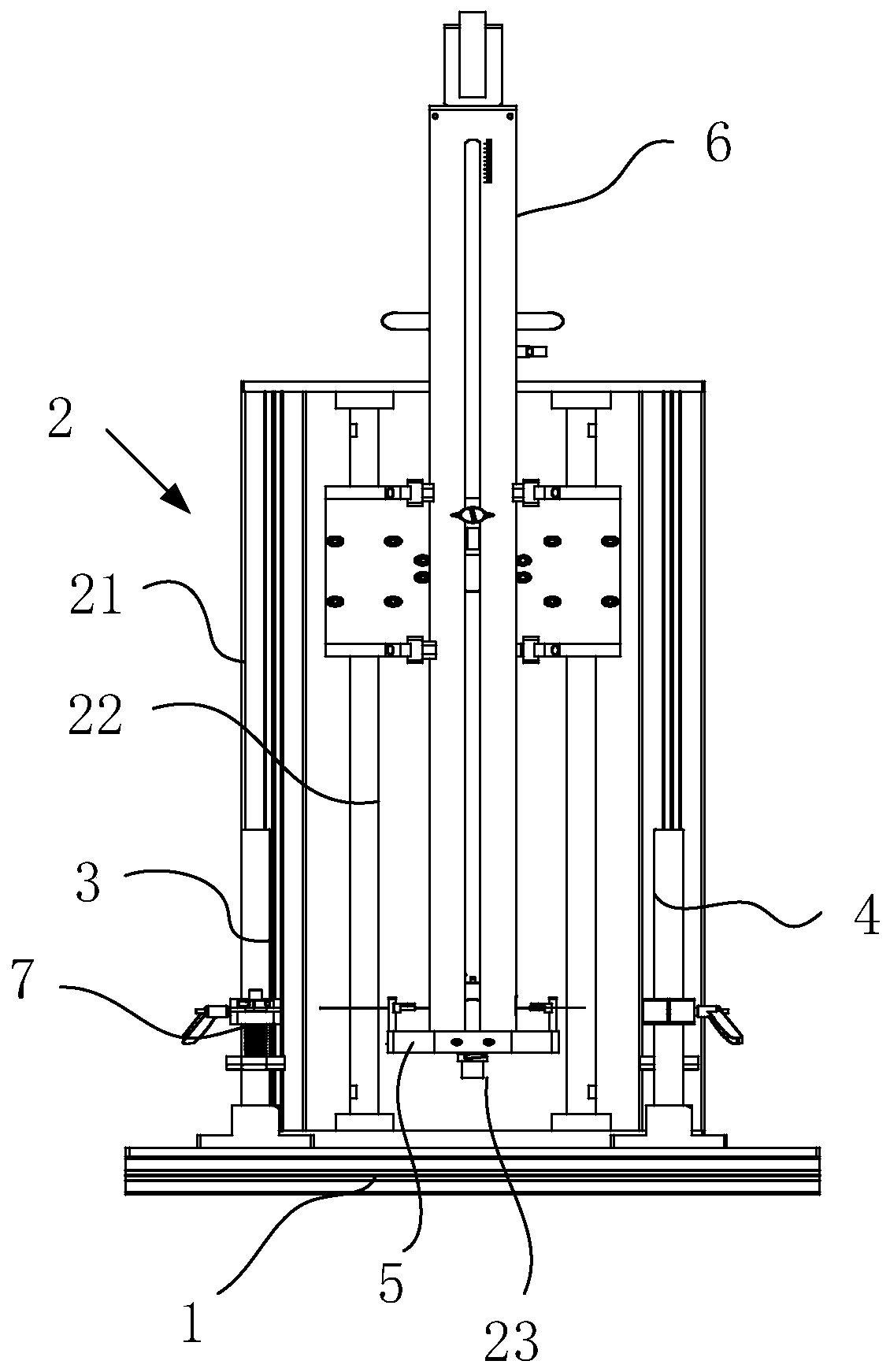

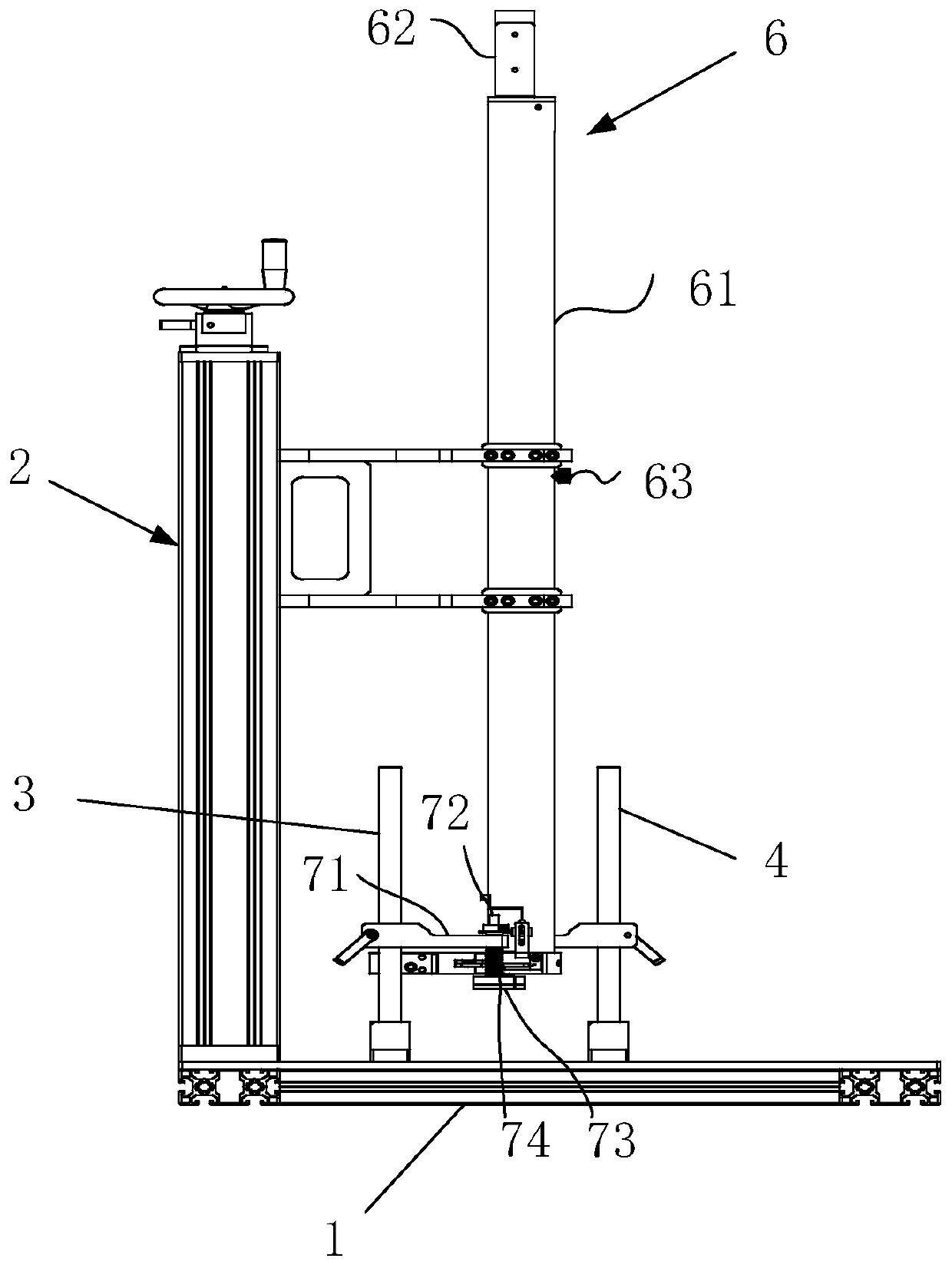

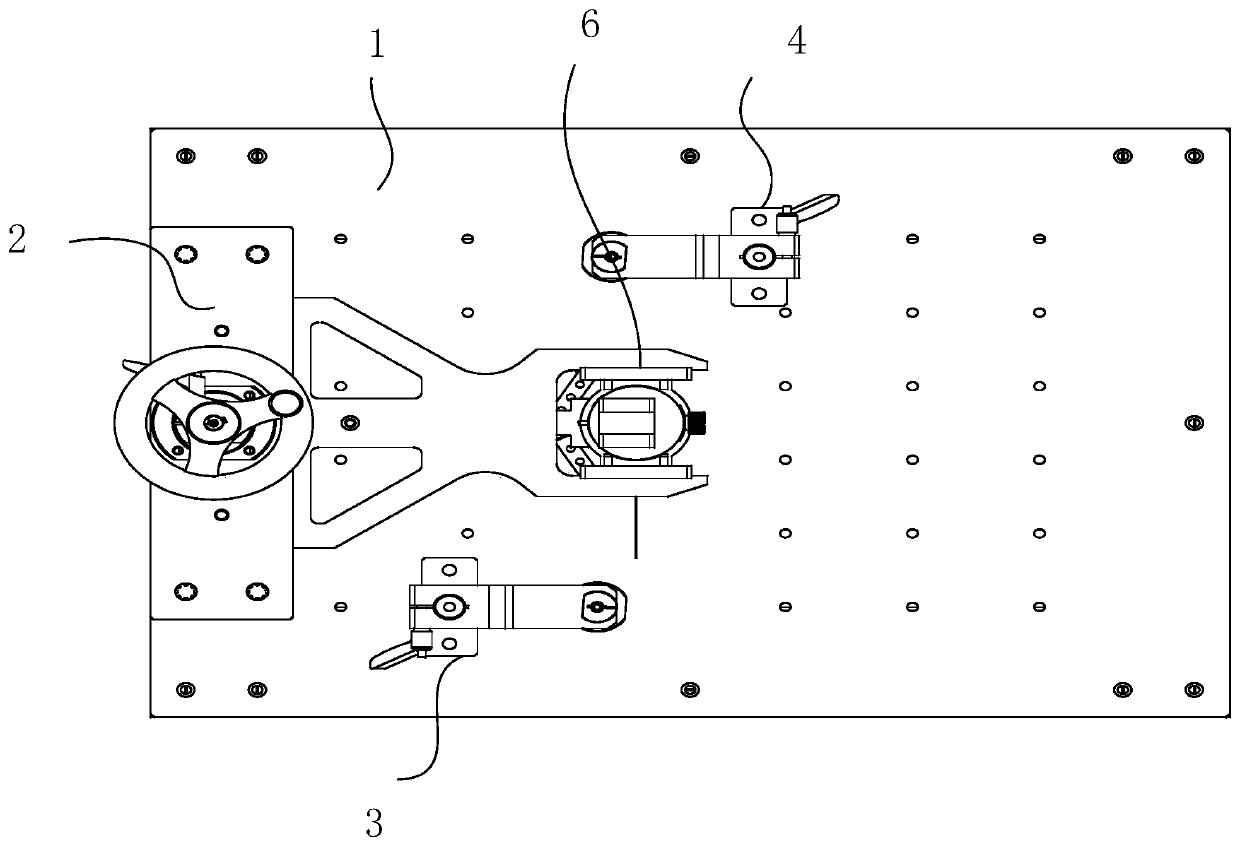

[0025] Such as figure 1 , figure 2 and image 3 as shown,

[0026] A drop tester for preventing secondary impact, comprising a base 1, a height adjustment mechanism 2 is arranged on one side of the base 1, and a first sample holder 3 and a second sample holder are also arranged on the base 1 4. The first sample fixing frame 3 and the second sample fixing frame 4 are arranged in dislocation, and the first sample fixing frame 3 and the second sample fixing frame 4 are both provided with a product fixing mechanism 7, and the two are opposite to each other. Setting, the height adjustment mechanism 2 is provided with a falling ball impact mechanism 6, which rises and falls synchronously with the height adjustment mechanism 2, and the falling ball impact mechanism 6 is located between the first sample holder 3 and the second sample holder 4, the The falling ball impact mechanism 6 is provided with an anti-secondary impact mechanism 5 located at the bottom of the falling ball imp...

Embodiment 1

[0032] Such as Figure 4 As shown, on the basis of the above-mentioned embodiments, the anti-secondary impact mechanism 5 in the present invention includes a sleeve 54, and the sleeve 54 is sleeved on the bottom end of the drop tube 61, and the left and right sides in the sleeve 54 Both sides are provided with guide rods, the second spring 52 is sleeved on the guide rod, and a push block is arranged on the outside of the second spring 52, and a strut is provided on the rear end of the drop tube 61, and the strut A cylinder is arranged on the top, which is connected with the push block. The front end of the pole is provided with a first chuck 53 and a second chuck 55 through the rotating shaft, which are arranged in a U-shaped structure, and are also separately arranged on both sides of the bottom of the drop tube 61 , the first chuck 53 and the second chuck 55 located on both sides of the drop tube 61 are connected to the respective corresponding push blocks. When the cylinder...

Embodiment 2

[0035] On the basis of the above-mentioned embodiment and the first embodiment, the ball drop tube 61 in the present invention is provided with a sensor for detecting the ball drop, which is located below the ball drop tube 61 and is lower than the height of the secondary rebound of the ball drop.

[0036] The sensor described in the present invention is an infrared sensor.

[0037] The working principle of the present invention is as follows:

[0038] During specific work, the product is placed on the clamp blocks on the first sample holder 3 and the second sample holder 4, and at the same time, the falling ball tube 61 in the falling ball impact mechanism 6 is fitted to the product through the height adjustment mechanism Place, then, the falling ball (iron ball) is promoted to the required height (adjusted according to demand) by the electromagnet height knob 63, and finally, the power-off treatment electromagnet height knob 63 loses magnetism, and the iron ball falls along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com