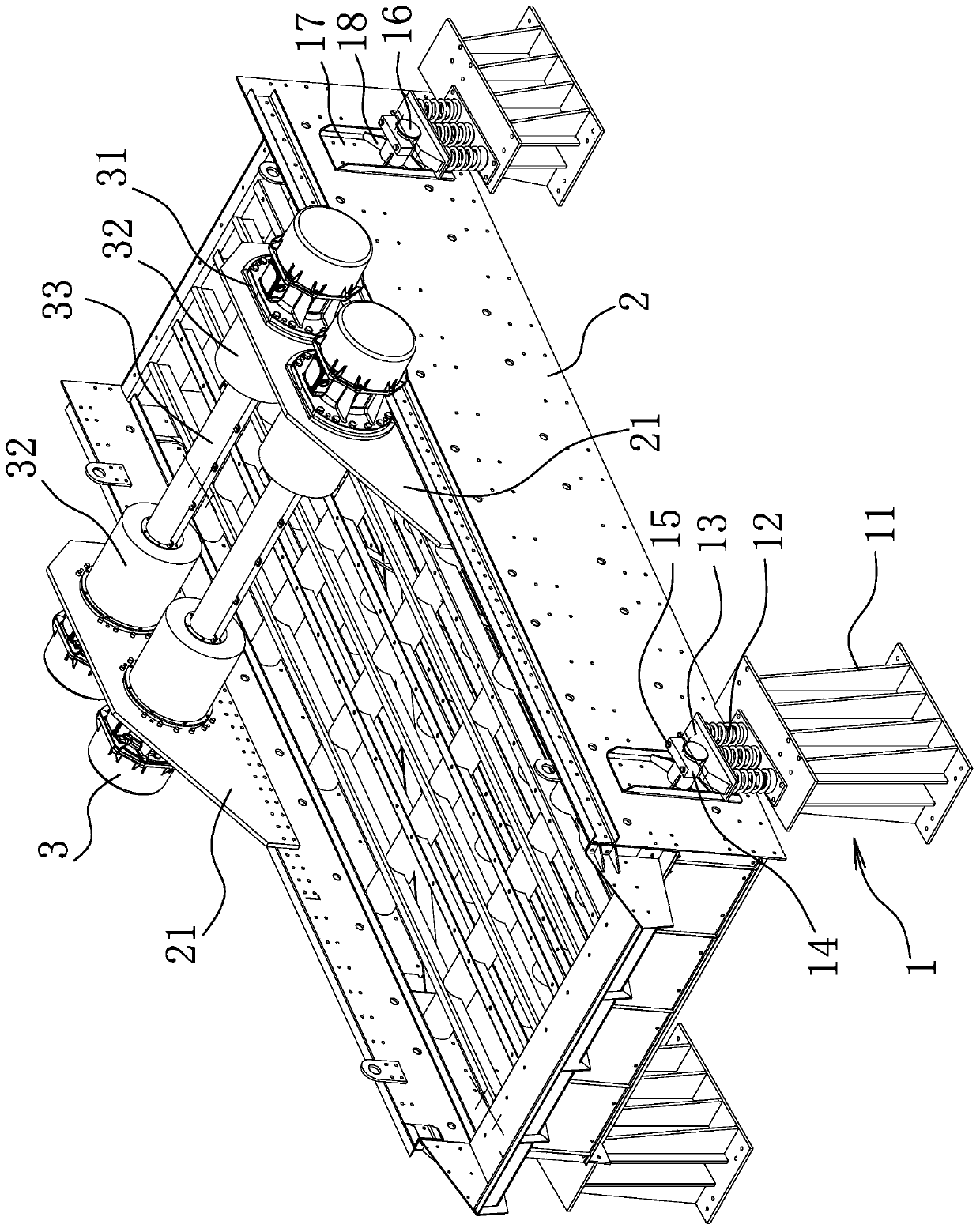

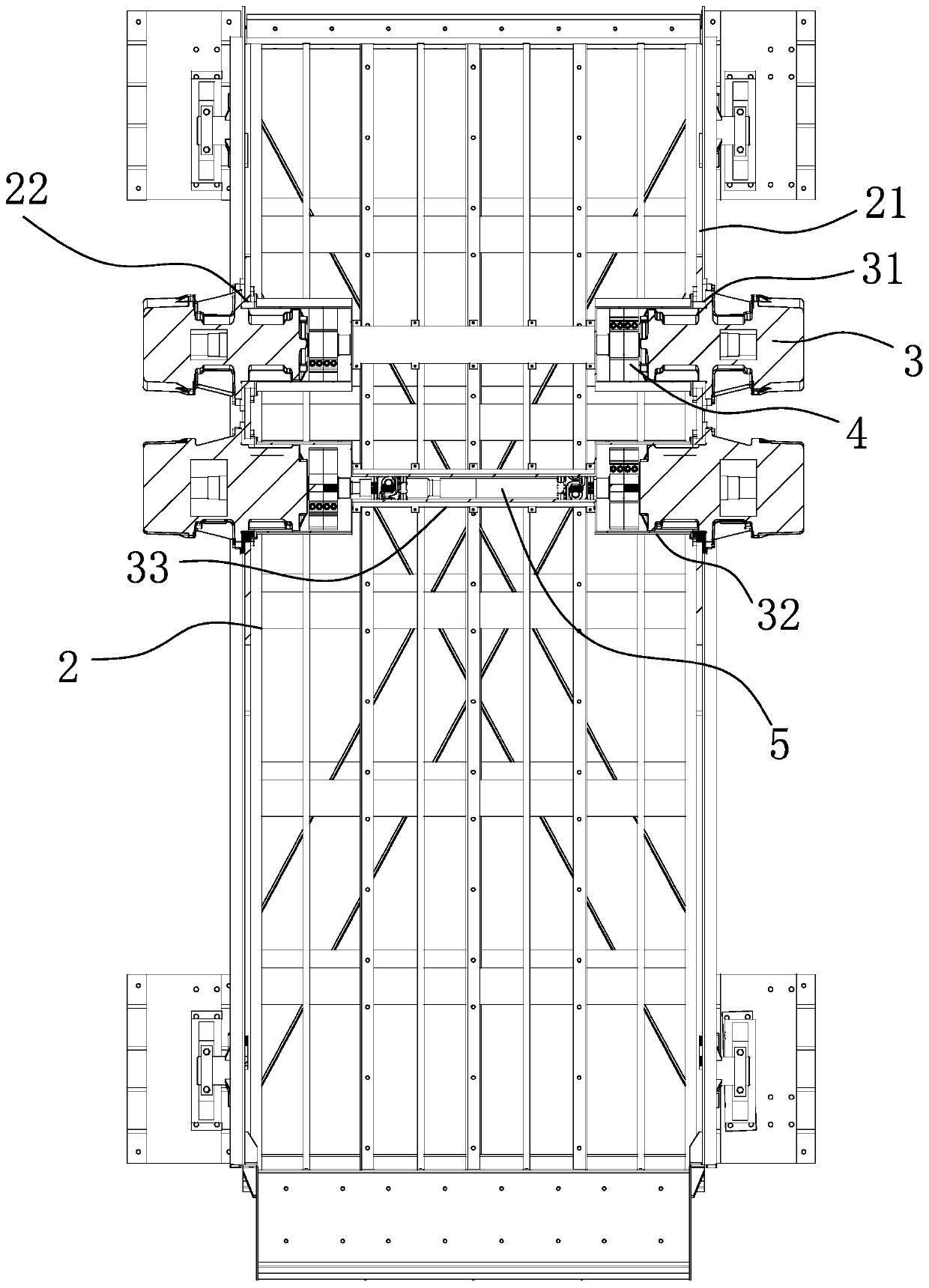

Oil-free direct-driven vibrating screen

A vibrating screen and direct drive technology, applied in the field of screening, can solve the problems of increased equipment manufacturing and installation costs, limited installation space in production workshops, increased packaging and transportation costs, etc., and achieve the effects of reasonable design, reduced complexity, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

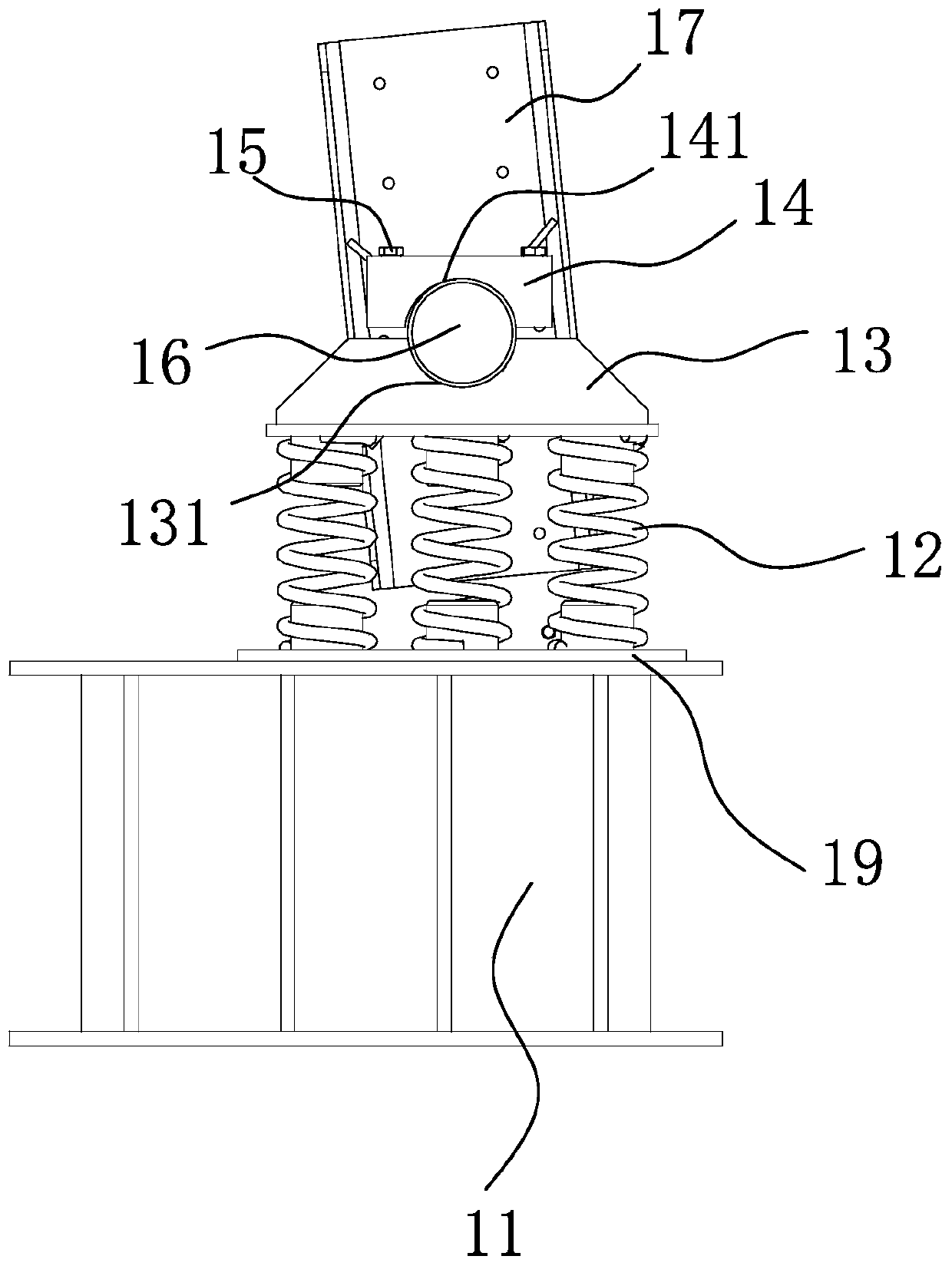

[0095] The working principle and structure of this embodiment are basically the same as those of the first embodiment, and the different structures are:

[0096] Such as Figure 7-9 As shown, the connecting mechanism 5 includes two connecting rods, a connecting rod 51 is connected to the output shaft of each vibration motor 3, and the opposite ends of the two connecting rods away from the vibration motor 3 are connected by a rubber member 5a.

[0097] The connecting rod 51 is sleeved on the output shaft of the vibration motor 3. The connecting rod 51 and the output shaft of the vibration motor 3 are connected by a number of radial screws. The axis lines of the two connecting rods 51 overlap each other. The end far away from the vibration motor 3 is provided with a connecting plate 52. The connecting plate 52 has a triangular structure. The rubber member 5a is a hexagonal rubber member. Each corner of one of the connecting plates 52 is provided with a connecting screw 53, three The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com