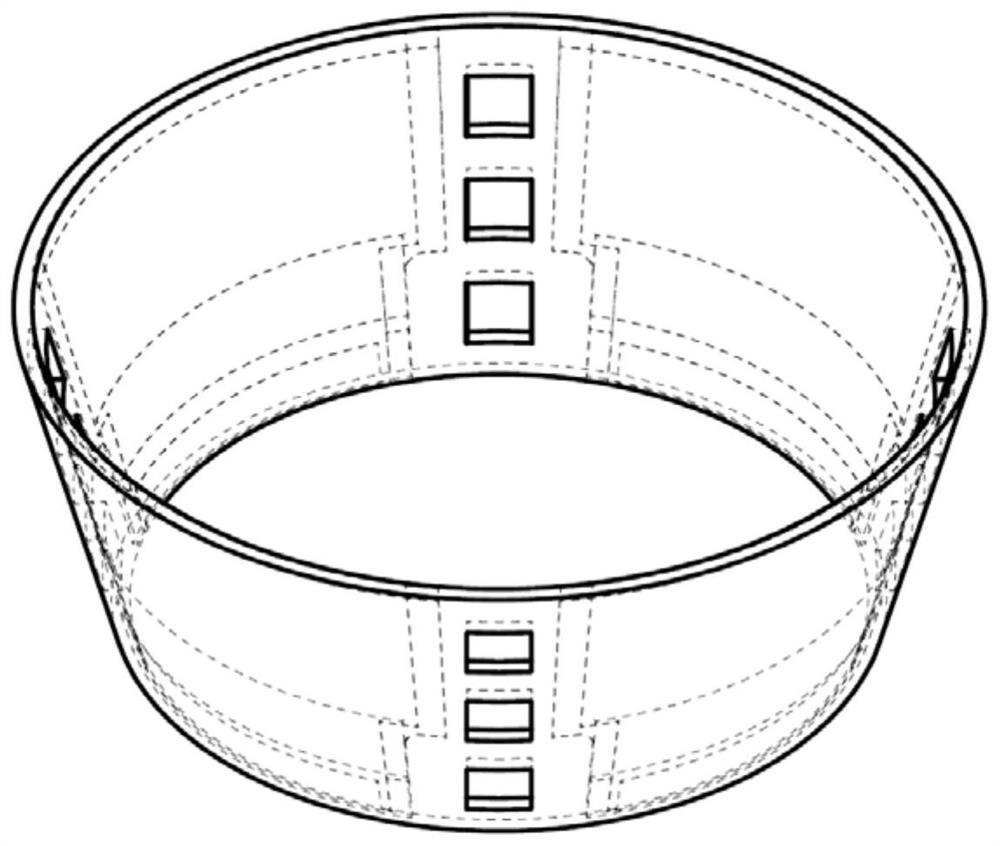

Turning tooling and method for large thin-walled conical aluminum alloy parts

An aluminum alloy and cone technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of difficult to control wall thickness, inconsistent cutting depth, affecting processing efficiency, etc., to reduce processing costs and ensure processing. Quality, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

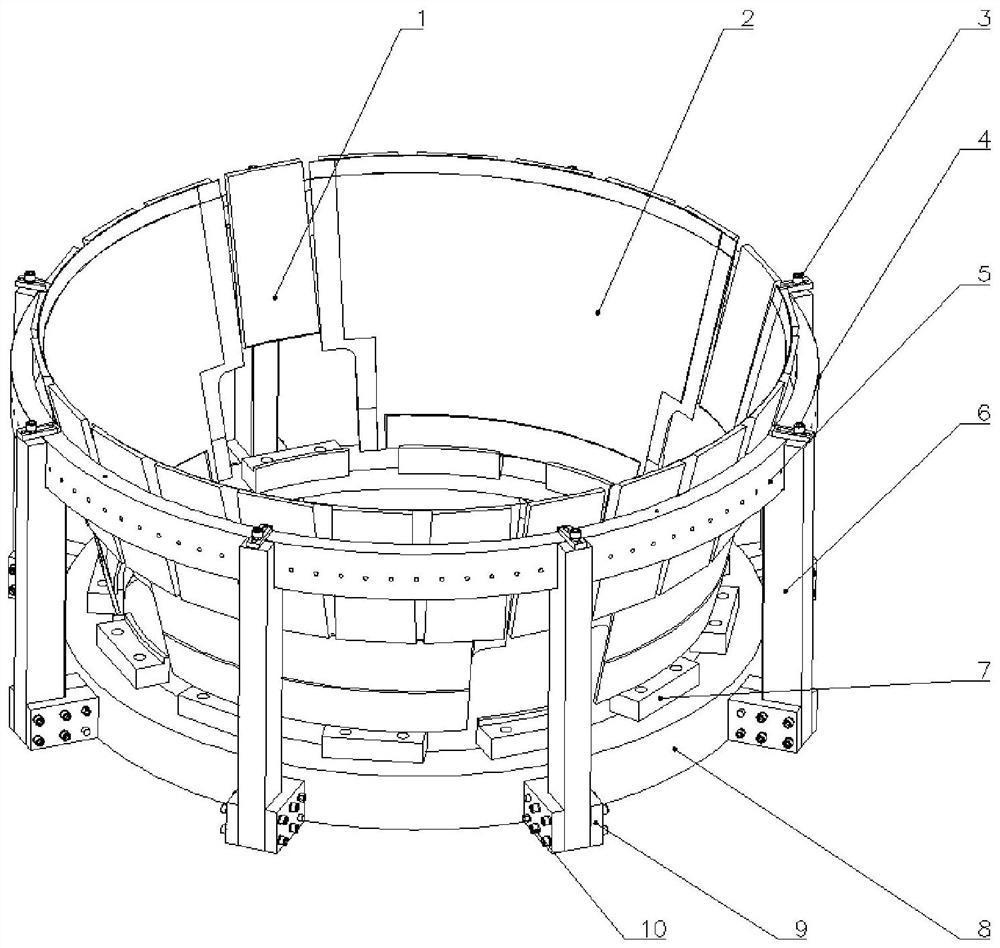

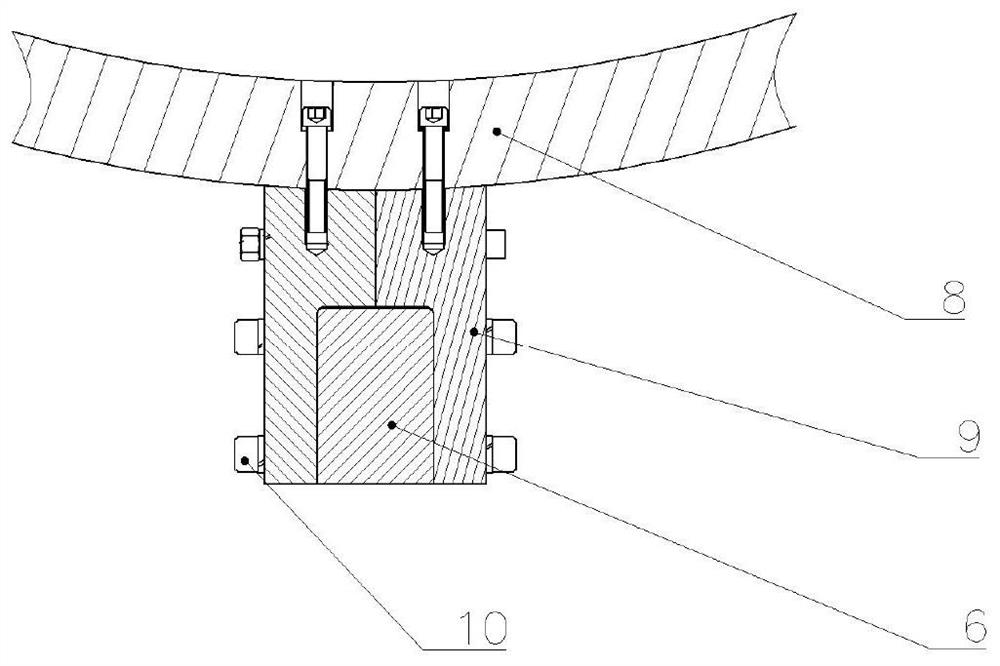

[0048] The supporting plate 1 described in the embodiment of the present invention is closely attached to the outer surface of the thin-walled conical aluminum alloy forging 2; Wall pre-drilled fixing holes for bolt support.

[0049] The invention provides a turning processing method of a large thin-walled conical aluminum alloy part. A new processing method is adopted to meet the thin-walled aluminum alloy forgings of different sizes, control the deformation of the parts during the processing, and ensure the consistency of the final processing wall thickness.

[0050] In order to achieve the above-mentioned purpose of the invention, the technical solution adopted by the present invention to solve the technical problem is to provide a turning method for large-scale thin-walled conical aluminum alloy parts, including:

[0051] Step 1. According to the size of the small end of the part, turn the reference bottom surface and the arc surface of the limit step on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com