Automatic polishing device for broken end of wire rod bending machine

A bending machine and automatic technology, which is applied in the direction of grinding drive, grinding machine, grinding feed movement, etc., can solve the problems of no protection for the control panel of the bending machine, and the inability to break and grind the wire, and achieve a simple structure , to avoid the effect of being accidentally touched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

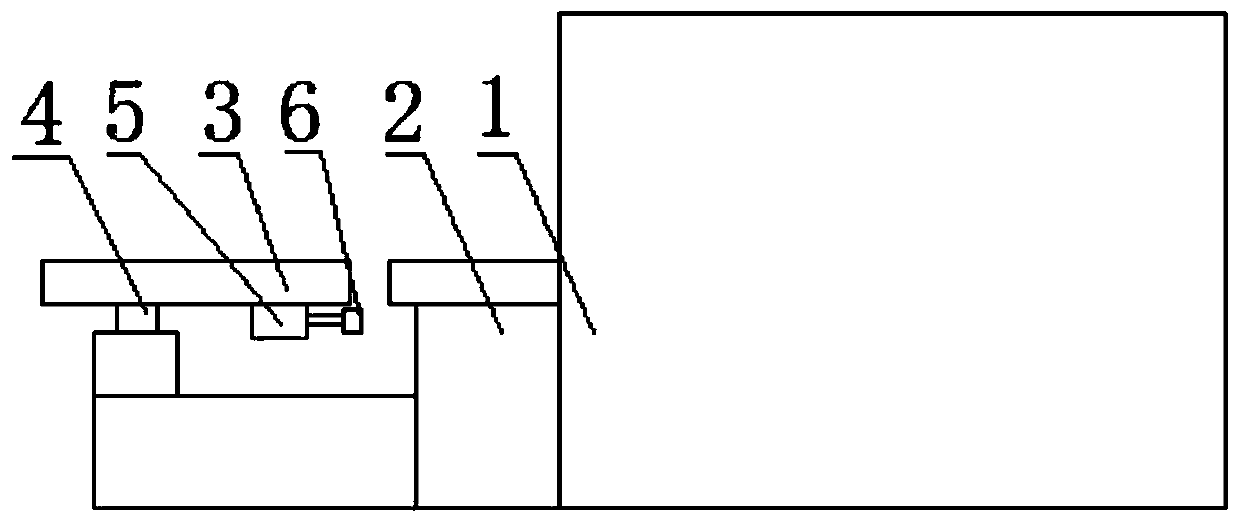

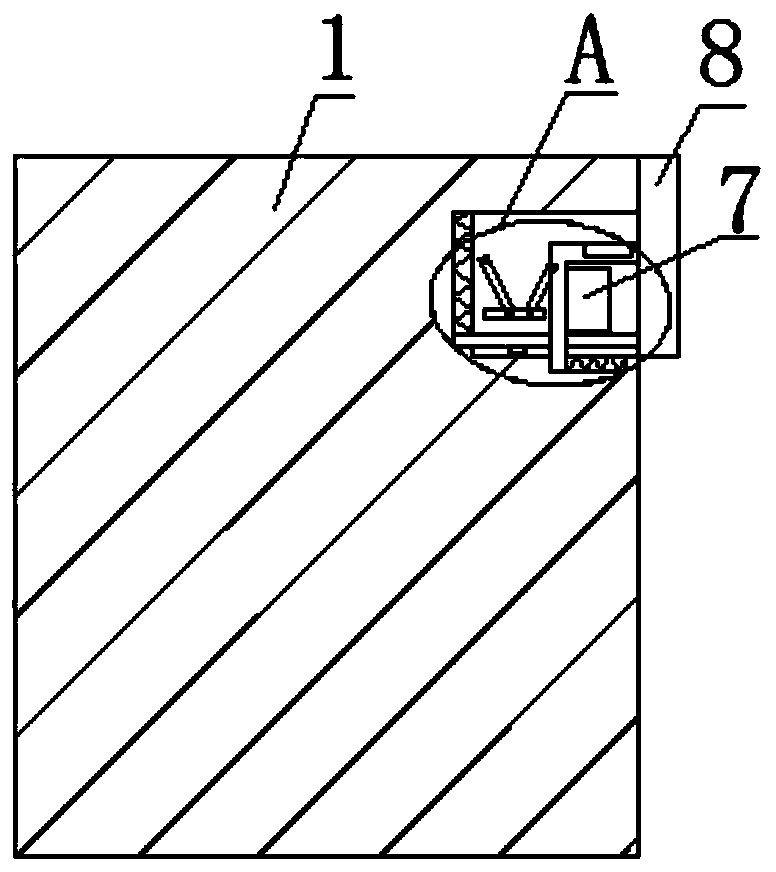

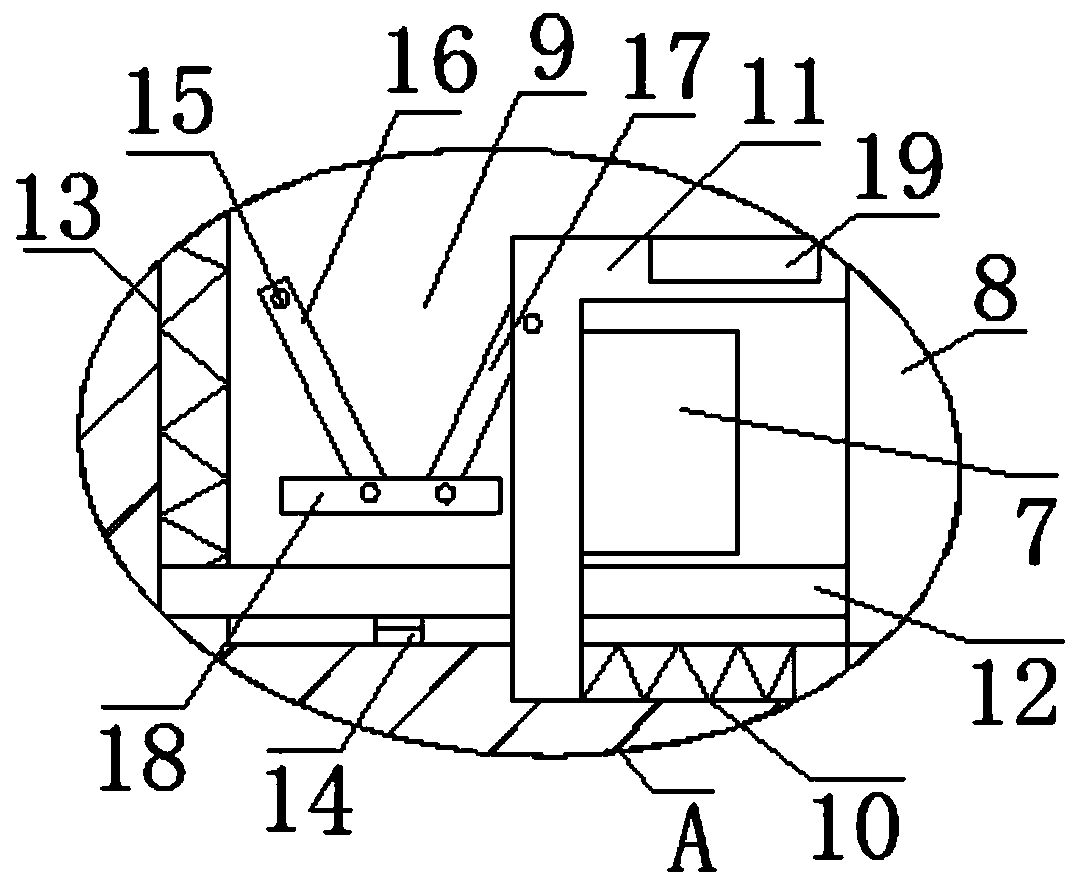

[0020] refer to Figure 1-3 , a wire bending machine broken end automatic grinding device, including a bending machine 1, one side of the bending machine 1 is provided with a discharge platform 2 and a blanking platform 3, the bending machine 1 is provided with a control panel 7, the bending machine A cylinder 4 is fixedly installed on the bending machine 1, and the output end of the cylinder 4 is fixedly installed on the bottom side of the unloading platform 3, and a motor 5 is fixedly installed on the bottom side of the unloading platform 3, and the output shaft of the motor 5 is fixedly installed through a coupling There is a rotating shaft, and one end of the rotating shaft is fixedly installed with a grinding head 6, and one side of the bending machine 1 is provided with a mounting groove 9, and a chute 10 is provided on the inner wall of the bottom side of the mounting groove 9, and an L-shaped The plate 11 and the control panel 7 are installed on one side of the L-shape...

Embodiment 2

[0026] refer to Figure 1-3 , a wire bending machine broken end automatic grinding device, including a bending machine 1, one side of the bending machine 1 is provided with a discharge platform 2 and a blanking platform 3, the bending machine 1 is provided with a control panel 7, the bending machine The bending machine 1 is fixed with a cylinder 4 by bolts, the output end of the cylinder 4 is fixed on the bottom side of the unloading platform 3 by bolts, the bottom side of the unloading platform 3 is fixed with a motor 5 by bolts, and the output shaft of the motor 5 A rotating shaft is fixedly installed by welding through a coupling, and one end of the rotating shaft is fixed with a grinding head 6 by a bolt. One side of the bending machine 1 is provided with a mounting groove 9, and a chute 10 is provided on the inner wall of the bottom side of the mounting groove 9. , an L-shaped plate 11 is slidably installed in the chute 10, and the control panel 7 is movably installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com