Rubber material strip cutting machine with fast cutter changing function

A technology of slitting machine and function, applied in metal processing and other directions, can solve the problems of scattered, time-consuming and labor-intensive, affecting factory production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

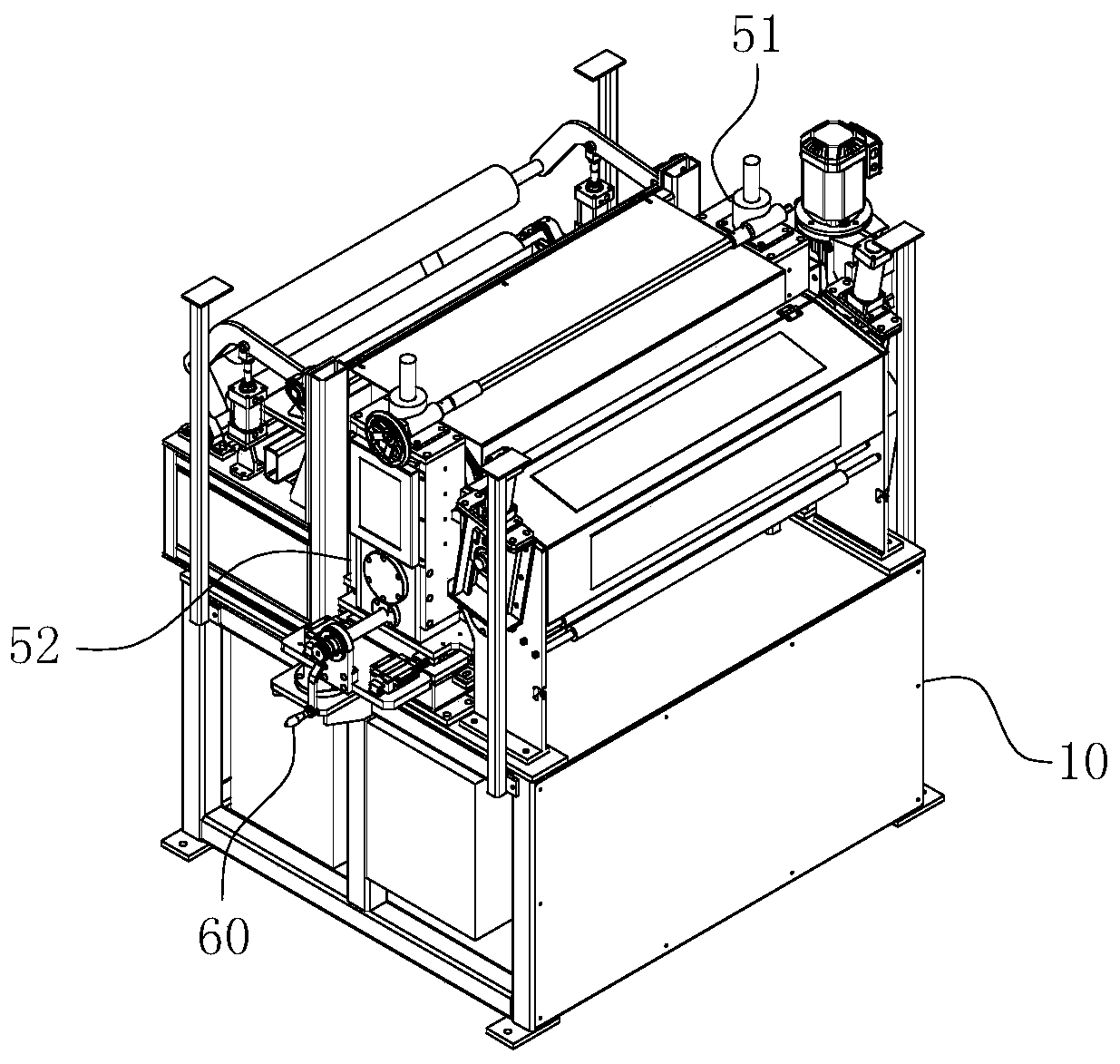

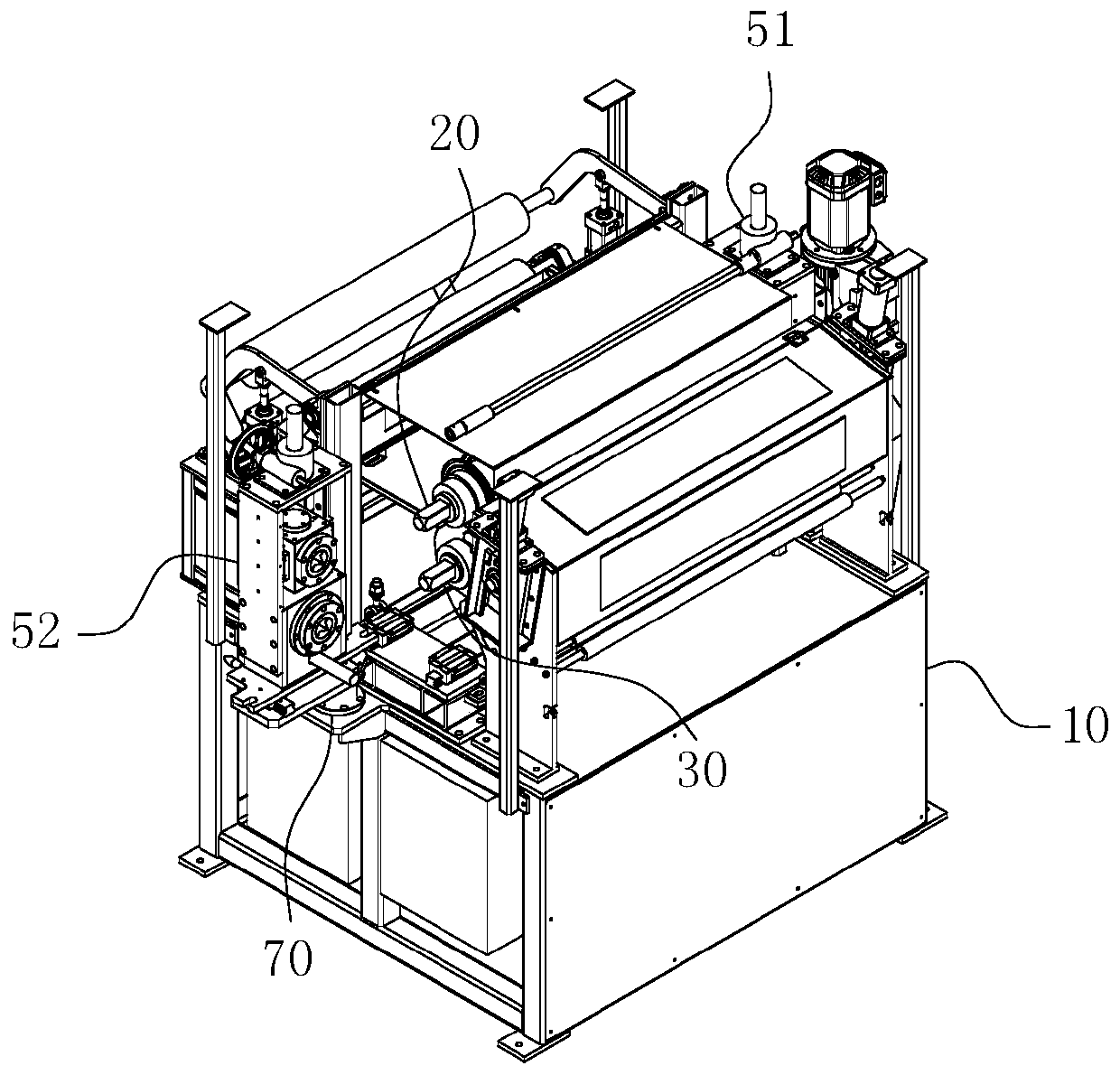

[0049] For ease of understanding, combined here Figure 1-13 , the concrete structure and working mode of the present invention are further described as follows:

[0050] The specific embodiment of the present invention is as Figure 1-2 As shown, its main structure includes a frame 10, on which a feed guide assembly, a cutter assembly and a discharge guide assembly are arranged, so that the rubber material can be guided by the rubber material guide assembly, and then cut and formed by the cutter assembly. Rubber strips, the rubber strips are exported through the discharge guide assembly, and finally delivered to the vulcanization area through packaging, storage and transportation processes. This improvement of the present invention is also aimed at the improvement of the cutter assembly. in:

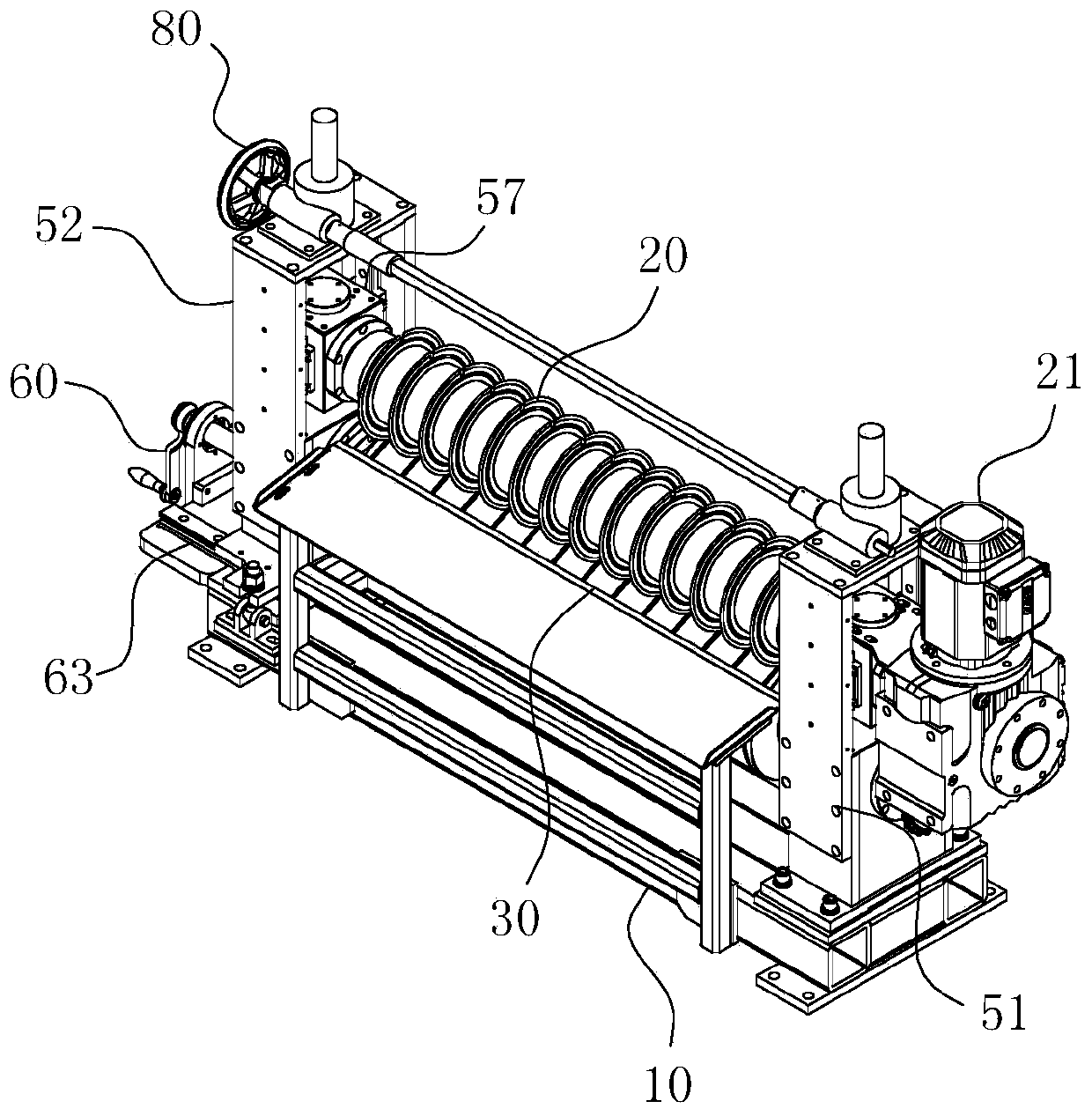

[0051] like Figure 3-12 As shown, the cutter assembly includes two sets of bearing supports, and an upper shaft body 20 and a lower shaft body 30 which are revolvingly fitted betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com