Tempered glass packaging and transporting device

A technology of tempered glass and transportation device, which is applied in transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve the problems of slippage and low glass stability, achieve improved stability, not easy to slip off, and save time in loading and unloading work Effort-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

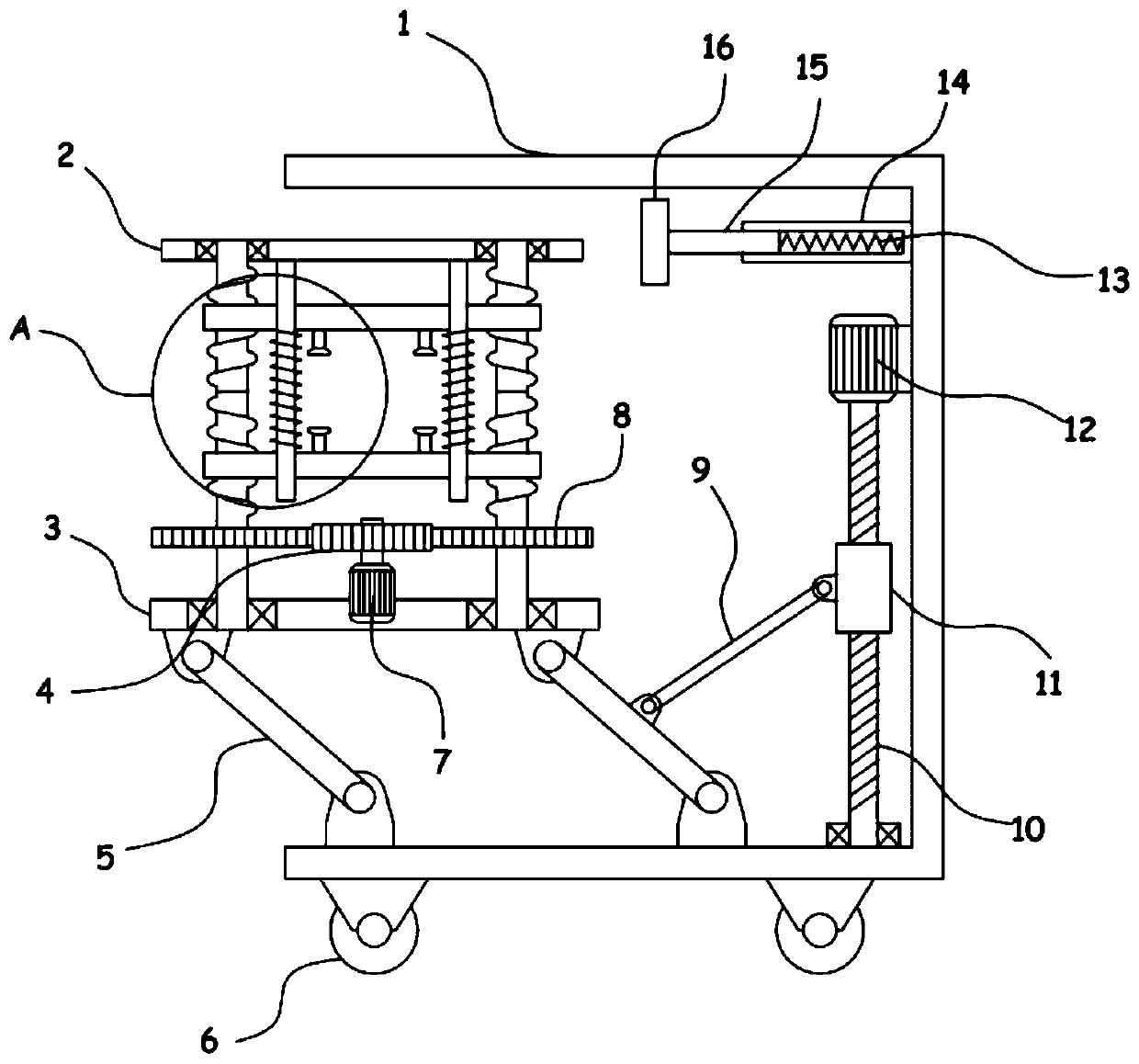

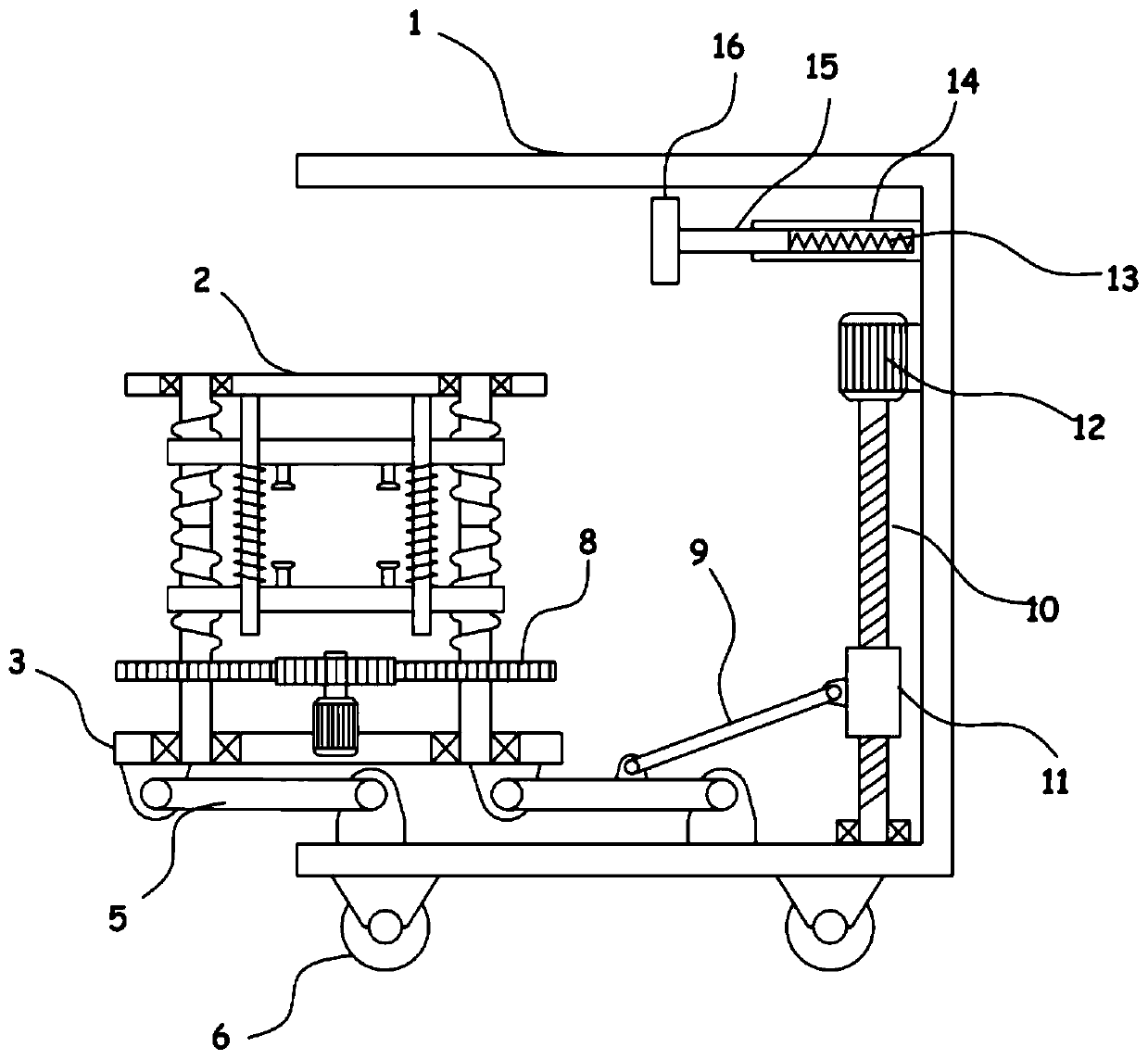

[0023] see Figure 1-4 , a tempered glass packaging and transporting device, comprising a transport box 1, the bottom of the transport box 1 is provided with a walking wheel 6 for driving the transport box 1 to move, the transport box 1 is provided with a support plate 3 that is adjusted up and down by a stretching mechanism, and the support plate 3 is fixedly installed with a servo motor I7, and the servo motor I7 is driven and connected with two pairs of adjustment mechanisms pivotally connected to the support plate 3 through the transmission assembly. A shock absorber assembly is provided between 19 and the lower clamp plate 22 .

[0024] During the packaging and handling of the tempered glass, the upper splint 19 and the lower splint 22 are arranged to move toward each other under the adjustment action of the adjusting mechanism, and clamp and fix the tempered glass. Transportation of tempered glass.

[0025] Specifically, the adjustment mechanism in the device includes ...

Embodiment 2

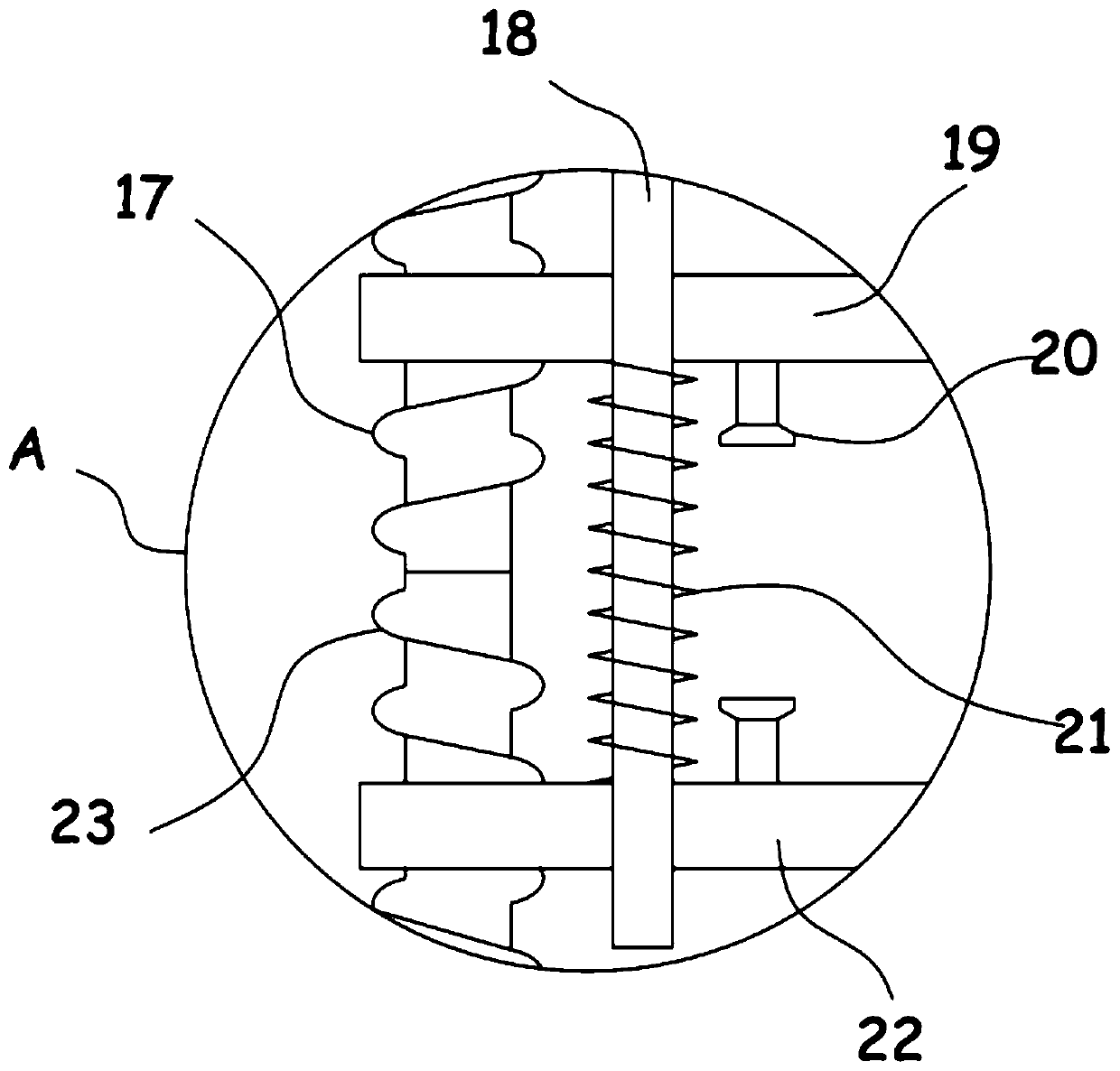

[0029] The upper splint 19 and the lower splint 22 are provided to clamp the tempered glass from the upper and lower sides. In order to ensure the stability of the clamping process and avoid the impact force of the upper splint 19 and the lower splint 22 on the tempered glass. On the basis of Example 1, in addition, the top plate 2 for the threaded rod I17 to be pivoted is provided above the upper clamp plate 19, and the damping assembly includes a sliding rod 18 vertically fixed on the bottom of the top plate 2, and the sliding rod 18 slides through the upper clamp plate 19 and the lower plate 18. A spring ring 21 fixed between the upper clamping plate 19 and the lower clamping plate 22 is provided on the clamping plate 22 and the sliding rod 18 on the sliding sleeve.

[0030] Through the above arrangement, when the upper splint 19 and the lower splint 22 move toward each other and clamp the tempered glass, the upper splint 19 and the lower splint 22 slide relative to the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com