Middle groove for automatic towing cable chain traction coal mining machine and scraper conveyer

A coal mining machine, automatic technology, applied in the field of middle trough and scraper conveyor, can solve the problems of tow cable chains being easy to drop and difficult to maintain, to reduce labor intensity and unsafe factors, not easy to drop the chain, and compact equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be described completely and clearly below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, not all of them.

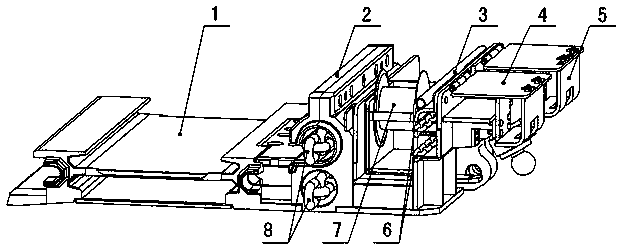

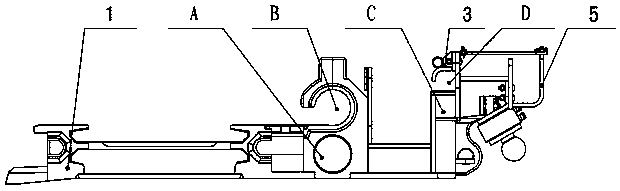

[0027] The present invention provides a kind of middle groove that is used for automatic towing cable chain traction shearer, such as figure 1 and figure 2 As shown, it includes the main tank body 1, the carriage cover 2, the tow cable upper chain cover 3, the cable groove cover plate 4, and the detachable cable groove 5; one end of the cable groove cover plate 4 is connected with the main groove body 1 through a pin shaft, and It is connected with the detachable cable groove 5, and the detachable cable groove 5 is connected with the main groove body 1 by bolts.

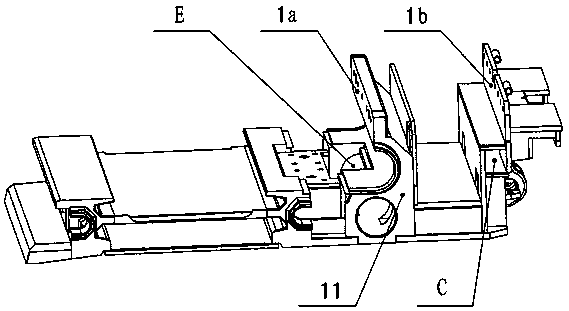

[0028] image 3 — Figure 6 As shown, the 2a surface on the carriage cover 2 and the 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com