Rainy season wet soft roadbed filling construction method

A construction method and roadbed technology, which is applied in the construction of grade highway base, small airport runway cushion, roadbed filling construction, railway roadbed, wet and soft roadbed filling construction in rainy season, can solve the problem that the optimum moisture content is difficult to grasp and improve Problems such as project cost and increase in the number of mechanical nests have been achieved to reduce the phenomenon of mechanical nests, reduce roadbed deformation, and speed up the progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

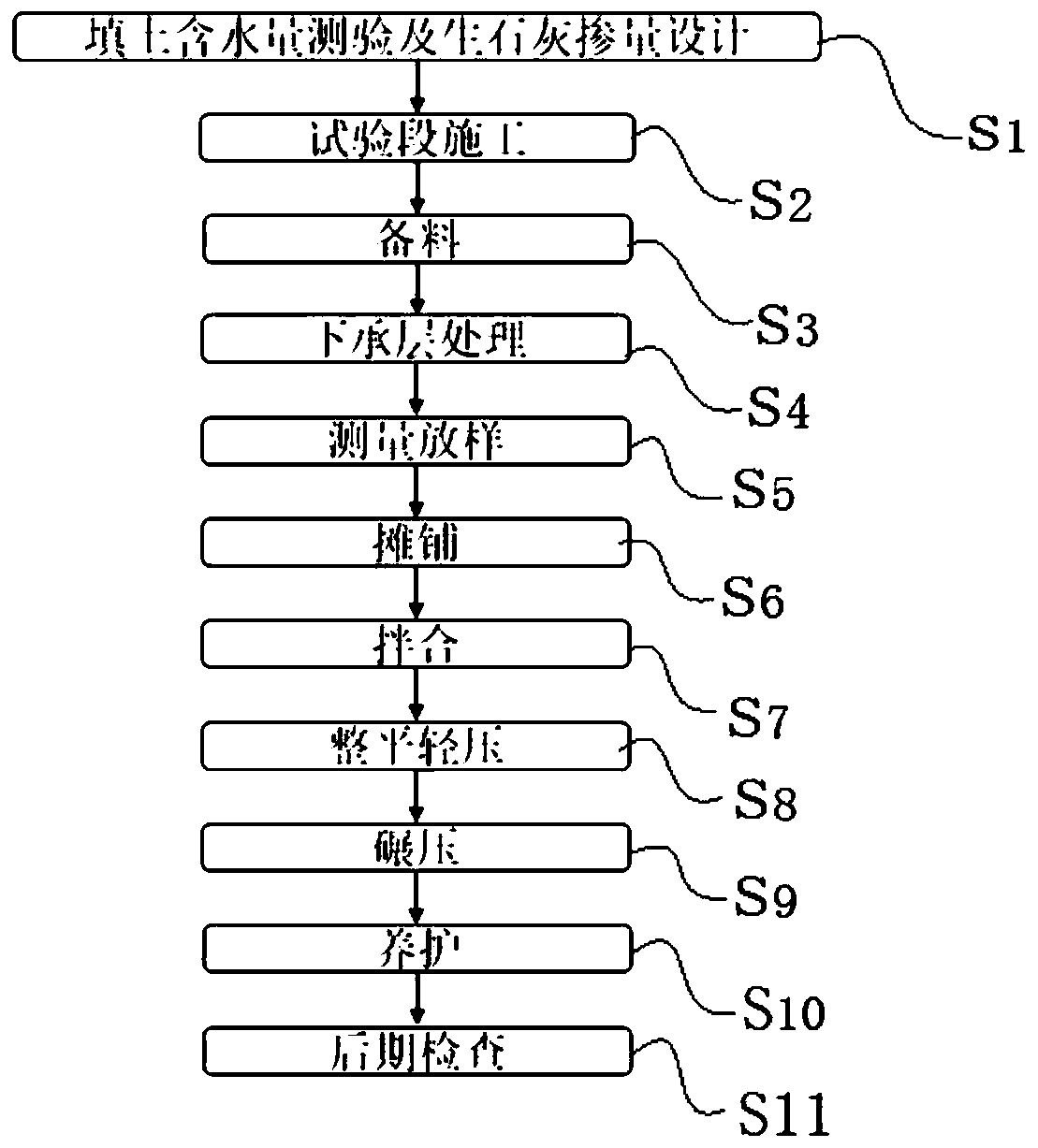

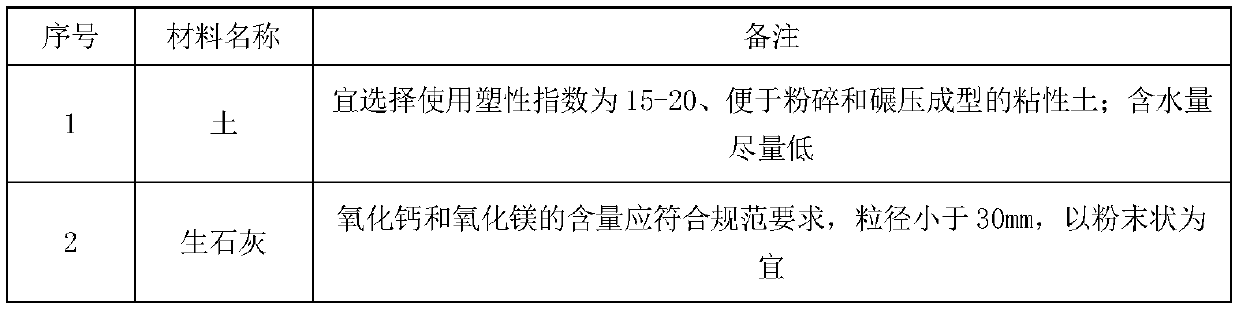

Method used

Image

Examples

Embodiment

[0056] This construction method is applicable to the construction of road bases of all grades, railway subgrades, and small airport runway cushions.

[0057] 1. Construction preparation

[0058] 1. According to the "Geological Survey Report", survey the construction site in detail, and be familiar with the surrounding underground trenches and adjacent buildings;

[0059] 2. Do a good job of setting up the site enclosure and the drainage ditches on both sides of the road in the construction site to prevent water accumulation in the site and ensure the smooth flow of construction machinery roads. Install water, electricity and temporary living facilities as needed before construction.

[0060] 3. Carry out a comprehensive on-site verification and construction investigation of the contents of the design materials and bidding documents, especially the amount of earthwork, traffic, vegetation, demolition of buildings and facilities, geological survey and other materials related to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com