A staggered high-efficiency enhanced geothermal injection-production single well structure and its completion method

An enhanced and staggered technology, applied in geothermal energy power generation, boreholes/well components, heat collectors using groundwater as the working fluid, etc., can solve the problem of poor heat transfer at the well end, difficulty in descaling, and impact on production Effect and other issues, to achieve the effect of easy descaling in the later stage, good practical application significance, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

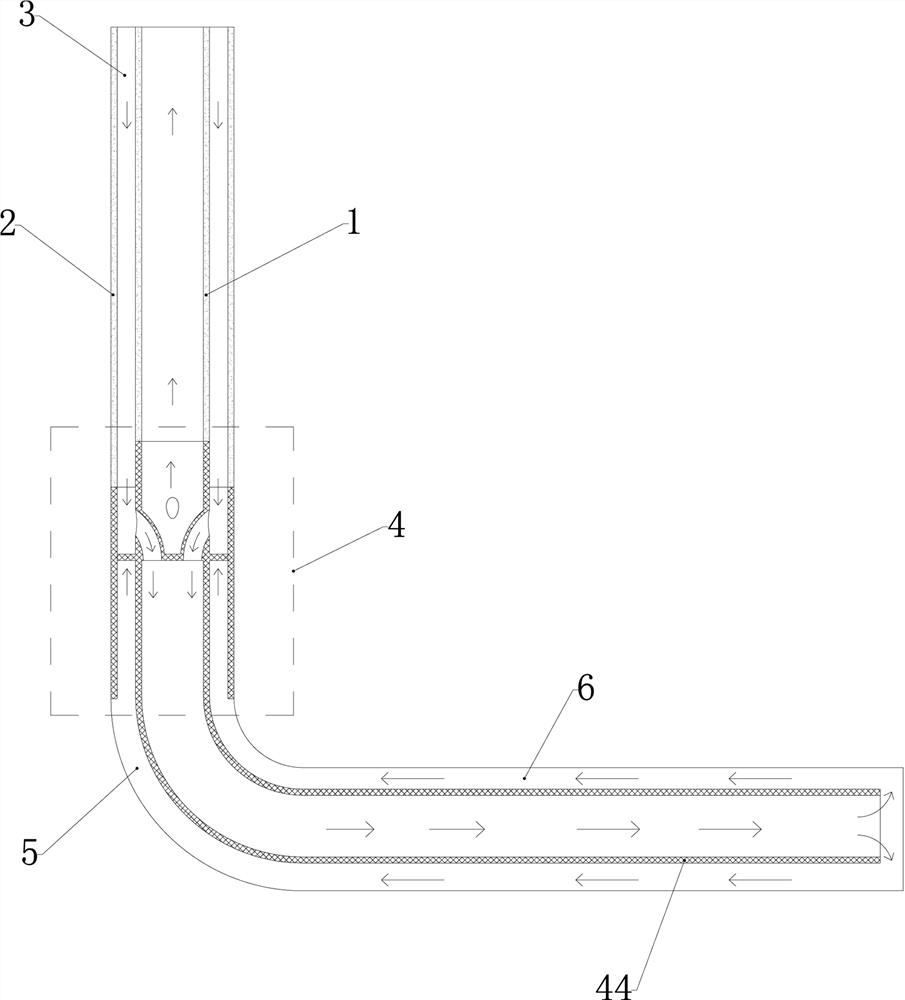

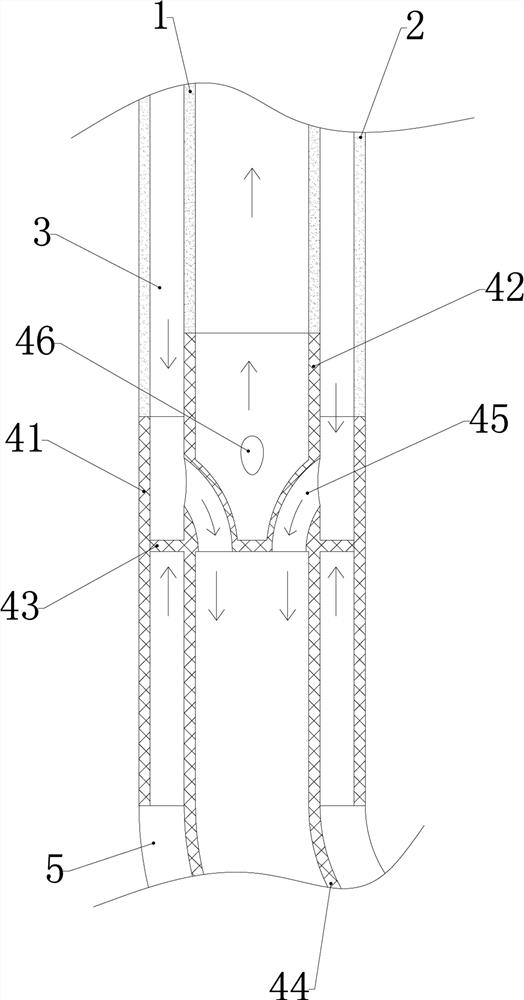

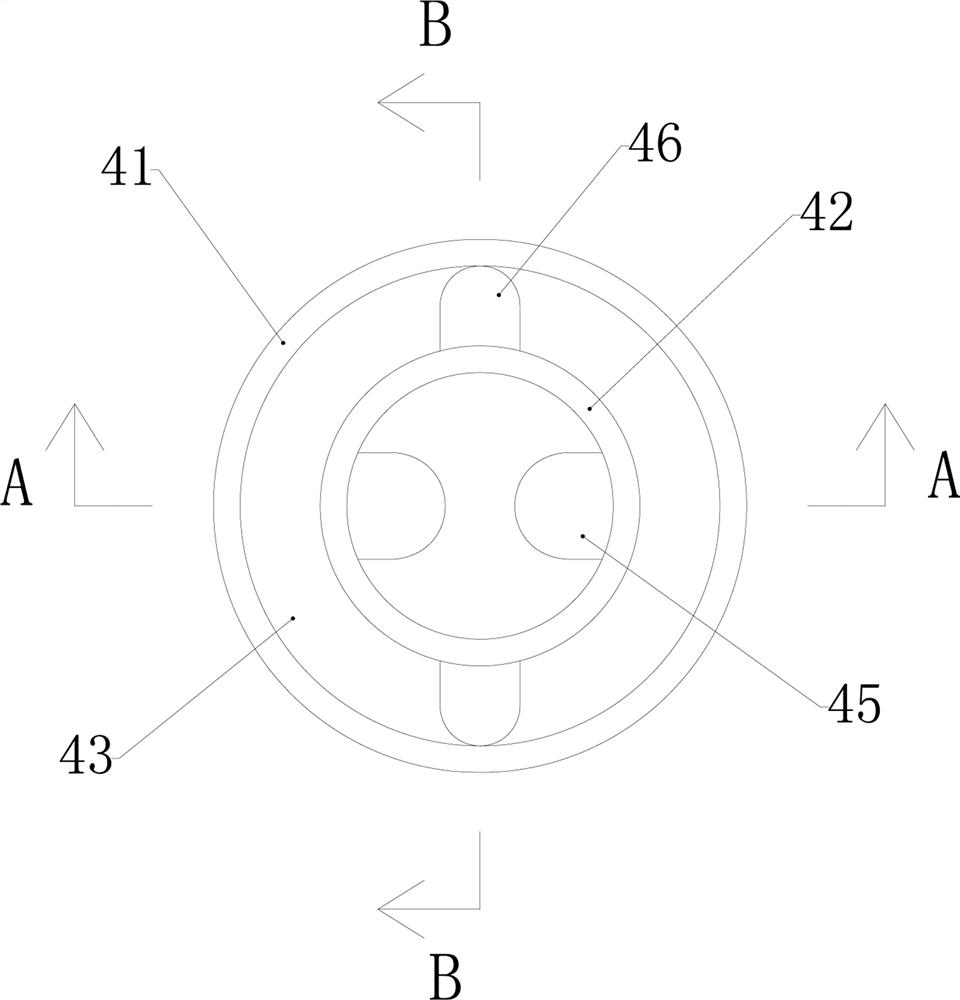

[0029] Such as Figure 1-6 As shown in , a staggered high-efficiency enhanced geothermal injection-production single well structure includes an inner pipe 1 and an outer pipe 2 arranged in a vertical well section, the inner pipe 1 and the outer pipe 2 are arranged coaxially, and the inner pipe 1 An annular space 3 is formed between the pipe 1 and the outer pipe 2, and a conversion mechanism 4 is installed in the vertical well section below the inner pipe 1 and the outer pipe 2, and the conversion mechanism 4 is used to direct cold water from it to the center of the well bottom The end flows out, and is used to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com