Air conditioner and air conditioner condensation-prevention method

An air conditioner and anti-condensation technology, which is applied in the prevention of condensed water, air-conditioning systems, heating methods, etc., can solve the problems of condensed water, customer inconvenience, etc., and achieve the effect of avoiding liquid shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

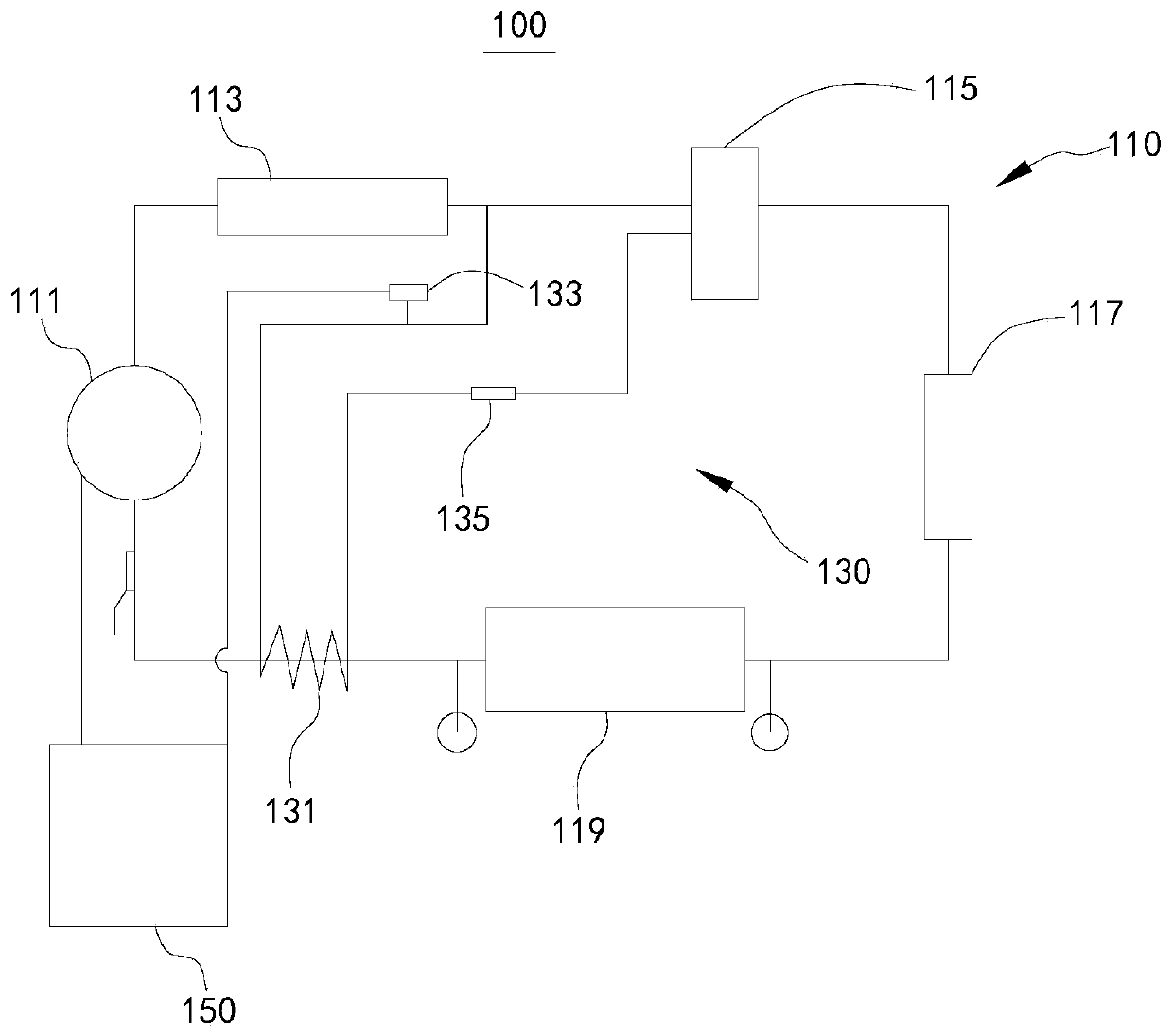

[0052] Please refer to figure 1 As shown, the air conditioner 100 provided in this embodiment can prevent the occurrence of liquid hammer phenomenon while preventing condensation water from being generated at the evaporator 119 .

[0053] The air conditioner provided in this embodiment includes a circulation loop 110, a heat recovery branch 130 and a controller 150. The circulation loop 110 is provided with a variable frequency compressor 111, a condenser 113, a liquid storage tank 115, an electronic expansion valve 117 and an evaporator in sequence. The output end of the evaporator 119 is directly connected to the input end of the inverter compressor 111 . That is, in the actual working process, the variable frequency compressor 111 outputs the high-temperature and high-pressure gaseous refrigerant to the condenser 113 to release heat, condenses into a medium-temperature and high-pressure liquid state, and then enters the liquid storage tank 115, and then is throttled through...

no. 2 example

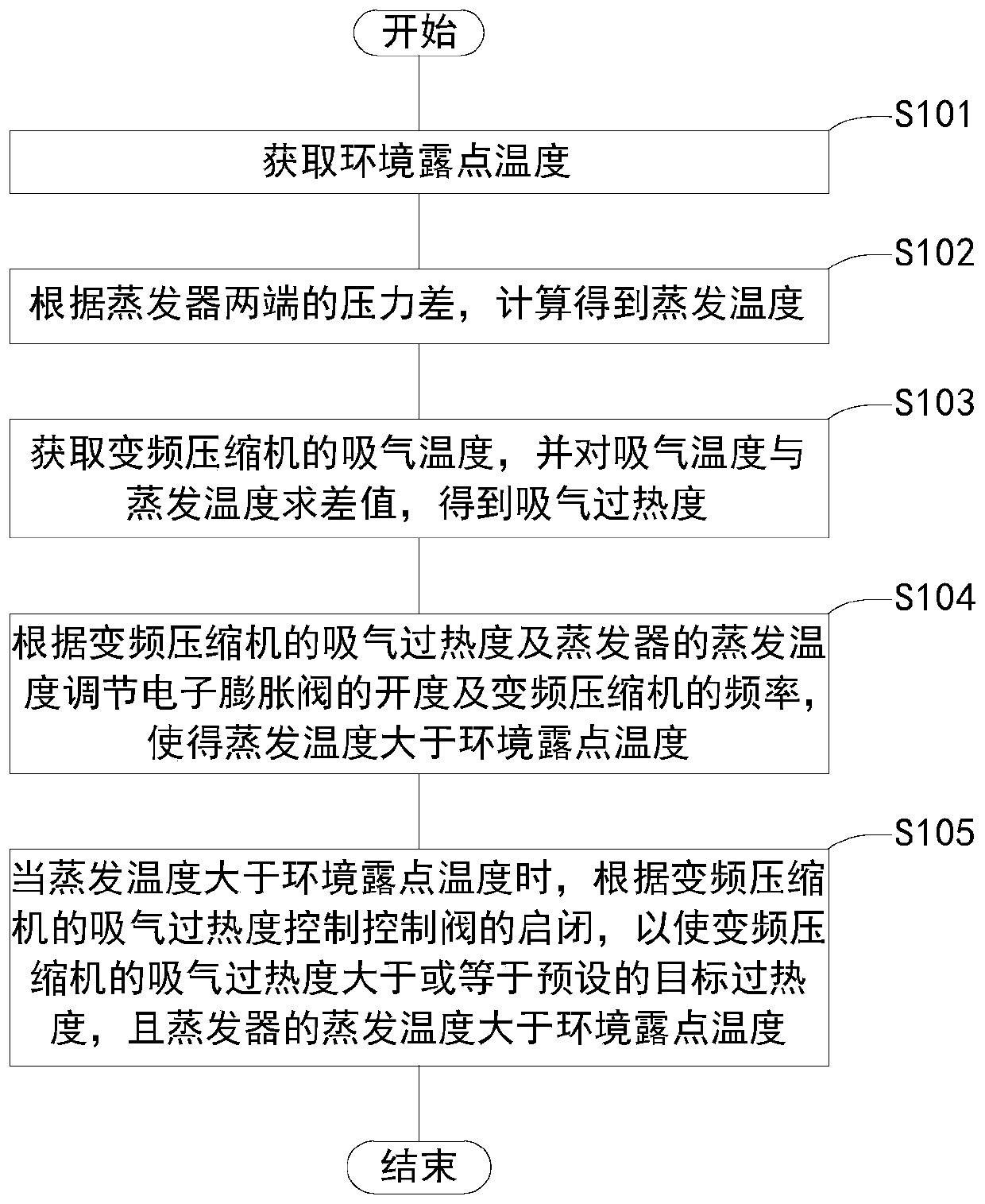

[0062] figure 2 For a schematic block diagram of the process flow of the air conditioner anti-condensation method for the air conditioner 100 provided in this embodiment, please refer to figure 2 As shown, the anti-condensation method of the air conditioner includes:

[0063] Step S101, obtaining the ambient dew point temperature.

[0064] After the air conditioner 100 is turned on, the controller 150 obtains the temperature and humidity of the indoor environment through the temperature and humidity sensor, and then calculates the ambient dew point temperature.

[0065] Further, the anti-condensation method for the air conditioner may also include:

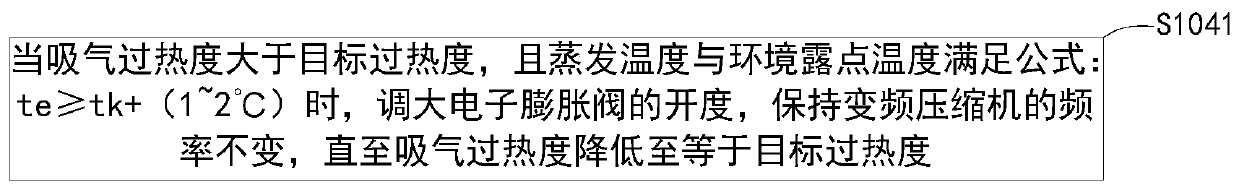

[0066] Step S102, calculating the evaporation temperature according to the pressure difference between the two ends of the evaporator.

[0067] The controller 150 receives the refrigerant pressure detected by the pressure sensors at both ends of the evaporator 119, performs an average calculation to obtain the evaporation pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com