Liquid crystal display panel, driving method thereof, and liquid crystal display device

A liquid crystal display panel and liquid crystal layer technology, applied in static indicators, instruments, nonlinear optics, etc., can solve the problems of high cost, large thickness, uncontrollable mirror reflection of liquid crystal display devices, etc., and reduce cost and process difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

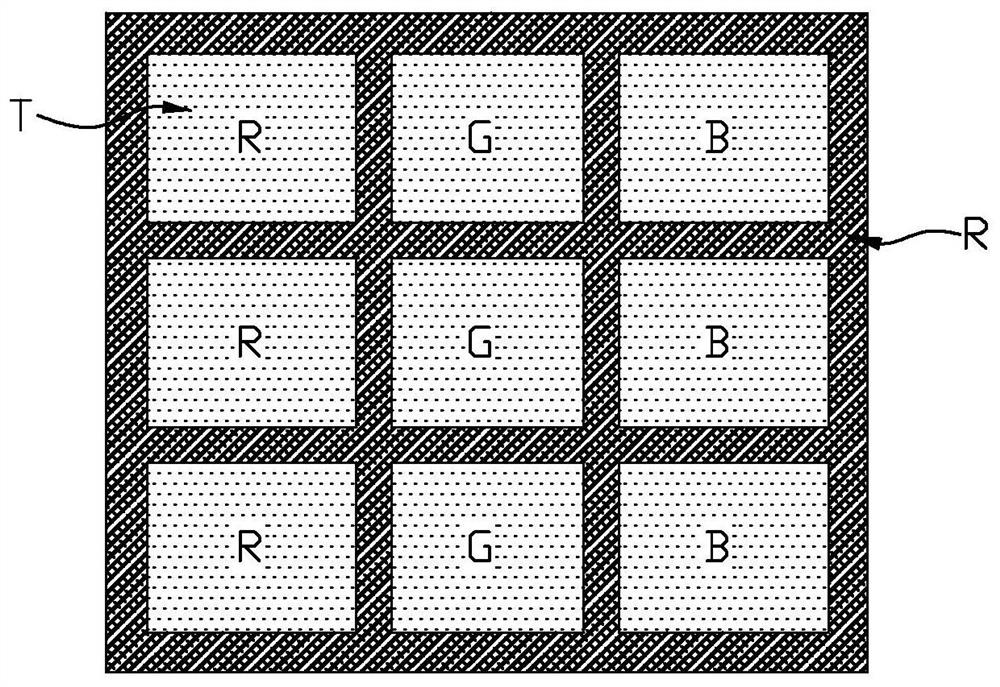

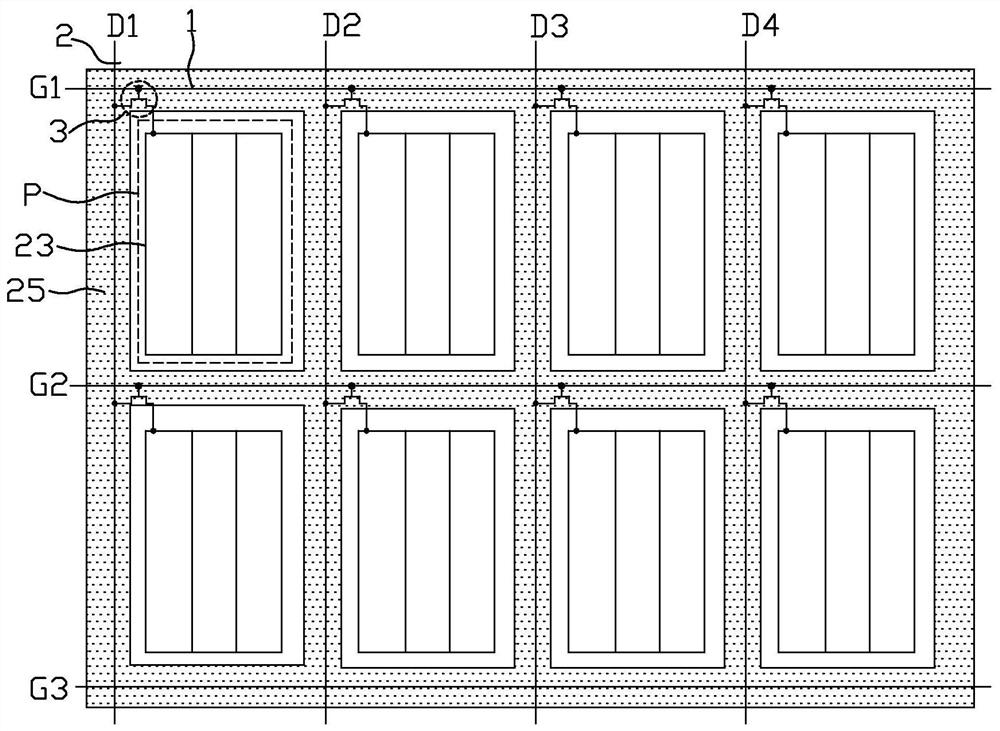

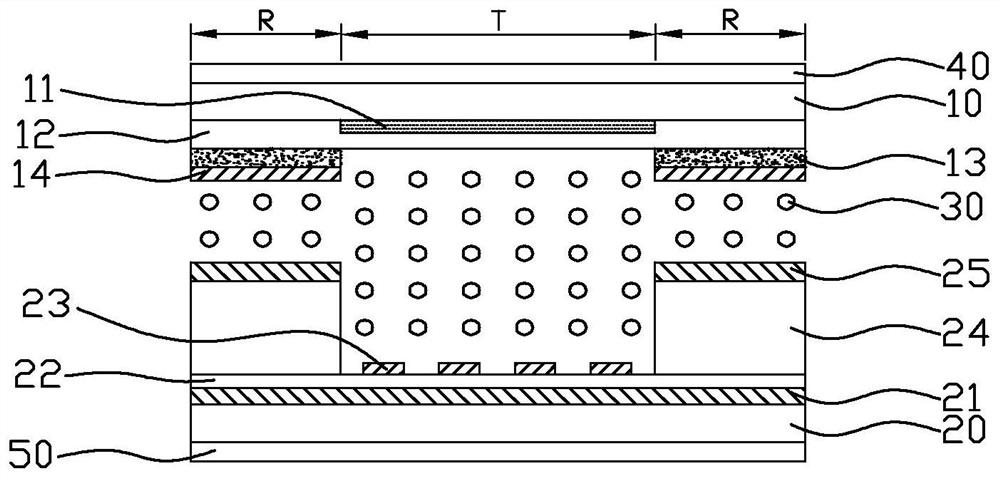

[0038] like Figure 1 to Figure 6 As shown, a liquid crystal display panel provided by the first embodiment of the present invention includes a first substrate 10 , a second substrate 20 disposed opposite to the first substrate 10 , and a liquid crystal layer located between the first substrate 10 and the second substrate 20 30. On the side facing the liquid crystal layer 30 of the second substrate 20, a plurality of scanning lines 1 and a plurality of data lines 2 are mutually insulated and intersected to form a plurality of pixel units P, and each pixel unit P is provided with a pixel electrode 23 and a The thin film transistor 3, the pixel electrode 23 is electrically connected to the scan line 1 and the data line 2 adjacent to the thin film transistor 3 through the thin film transistor 3, wherein the first substrate 10 is a color filter substrate, the second substrate 20 is an array substrate, and the thin film transistor 3 It includes a gate electrode, a source electrode ...

Embodiment 2

[0053] like Figure 7 As shown, the liquid crystal display panel provided by the second embodiment of the present invention is the same as that of the first embodiment ( Figure 5 ) are basically the same as the liquid crystal display panels in In the first wave plate 26 , the fast and slow axes of the second quarter wave plate 26 and the second light transmission axis X2 of the second polarizer 50 are at 45°. Because, using the entire first quarter-wave plate 13, it is necessary to attach the second quarter-wave plate 26 on the second substrate 20 side corresponding to the first quarter-wave plate 13, so as not to affect the transmission Normal display of zone T. Of course, the second quarter wave plate 26 only needs to correspond to the transmission region T, but this will increase the etching process.

[0054] In this embodiment, the first quarter-wave plate 13 is disposed between the first substrate 10 and the auxiliary electrode 14 , and the second quarter-wave plate 2...

Embodiment 3

[0058] like Figure 8 As shown, the liquid crystal display panel provided by the third embodiment of the present invention is the same as the second embodiment ( Figure 7 ) is basically the same as the liquid crystal display panel in The wave plate 26 is arranged between the second substrate 20 and the second polarizer 50. Of course, the first quarter wave plate 13 and the second quarter wave plate 26 can also be arranged in other layers according to actual requirements, for example , the first quarter-wave plate 13 is arranged between the first substrate 10 and the color resist layer 11 , and the second quarter-wave plate 26 is arranged between the second substrate 20 and the common electrode 21 . limited.

[0059] Compared with the second embodiment, in this embodiment, the first quarter-wave plate 13 is disposed outside the liquid crystal cell, that is, on the side of the first substrate 10 away from the liquid crystal layer 30 , which can reduce the difficulty of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com