Method for preparing color film array substrate and color film array substrate

An array substrate and color film technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of low aperture ratio, achieve the effect of increasing the aperture ratio, avoiding the need for apertures, and reducing the difficulty of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

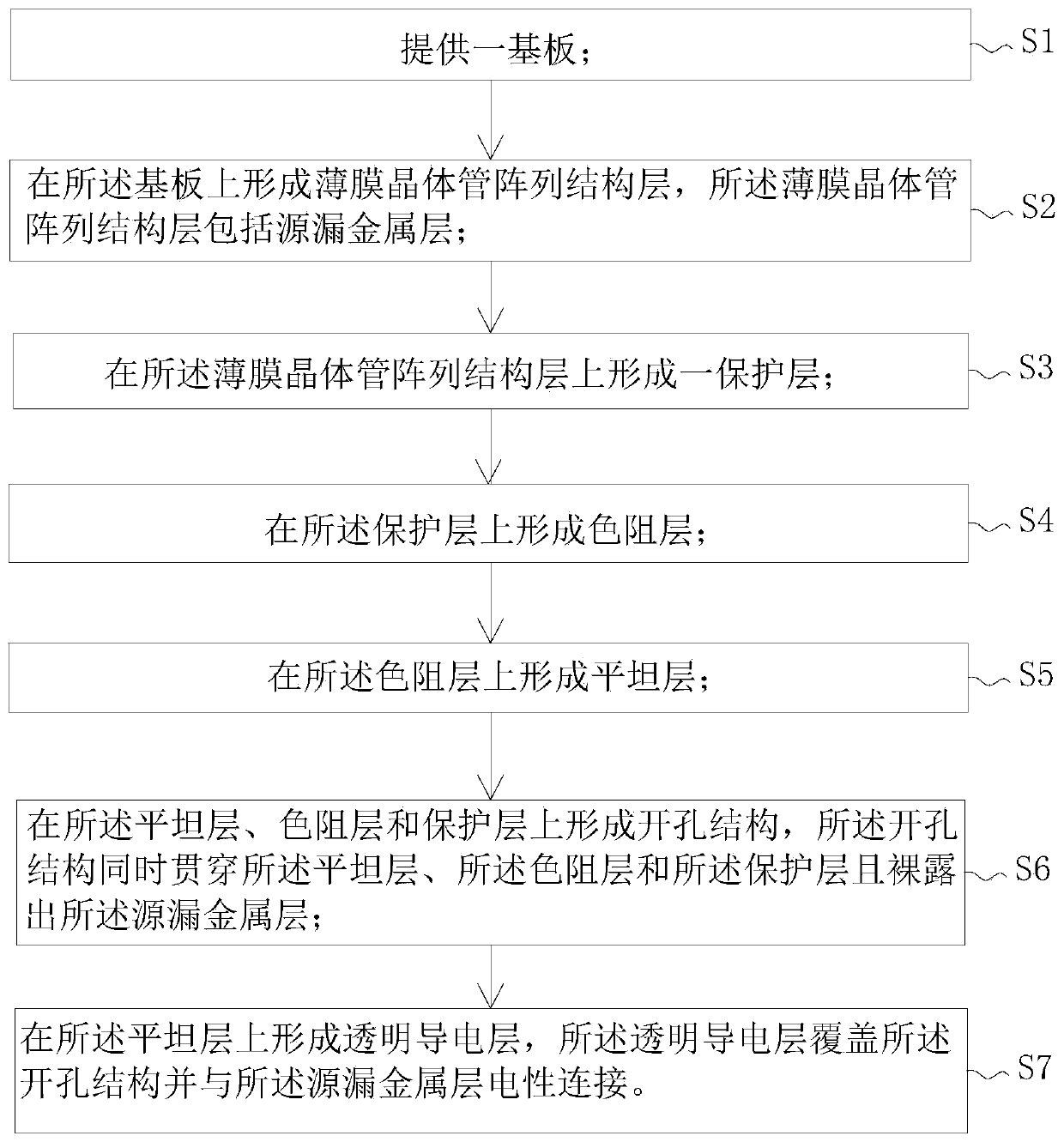

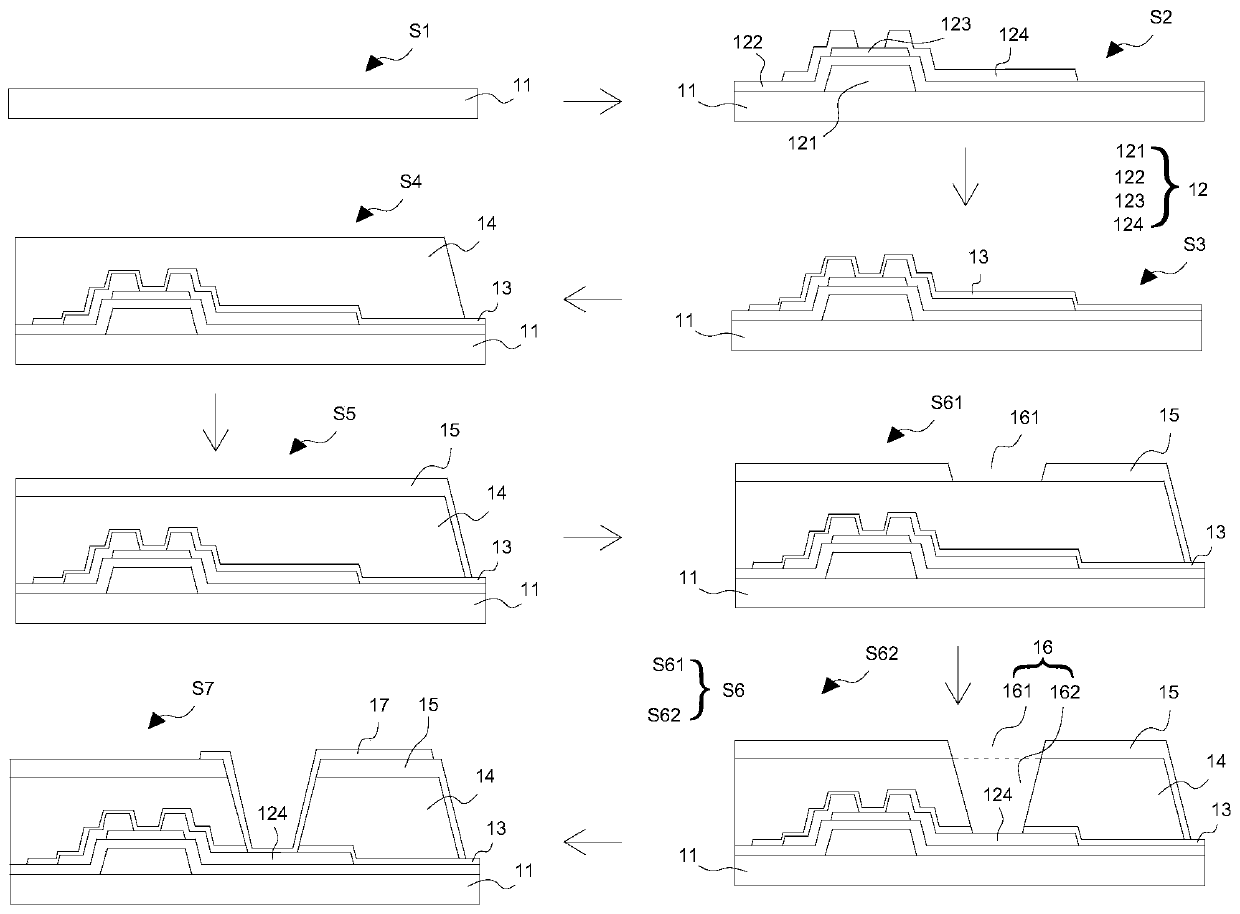

[0052] An embodiment of the present application provides a method for preparing a color filter array substrate, which includes the following steps:

[0053] S1: providing a substrate;

[0054] S2: forming a thin film transistor array structure layer on the substrate, the thin film transistor array structure layer including a source-drain metal layer;

[0055] S3: forming a protection layer on the thin film transistor array structure layer;

[0056] S4: forming a color resist layer on the protective layer;

[0057] S5: forming a flat layer on the color resist layer;

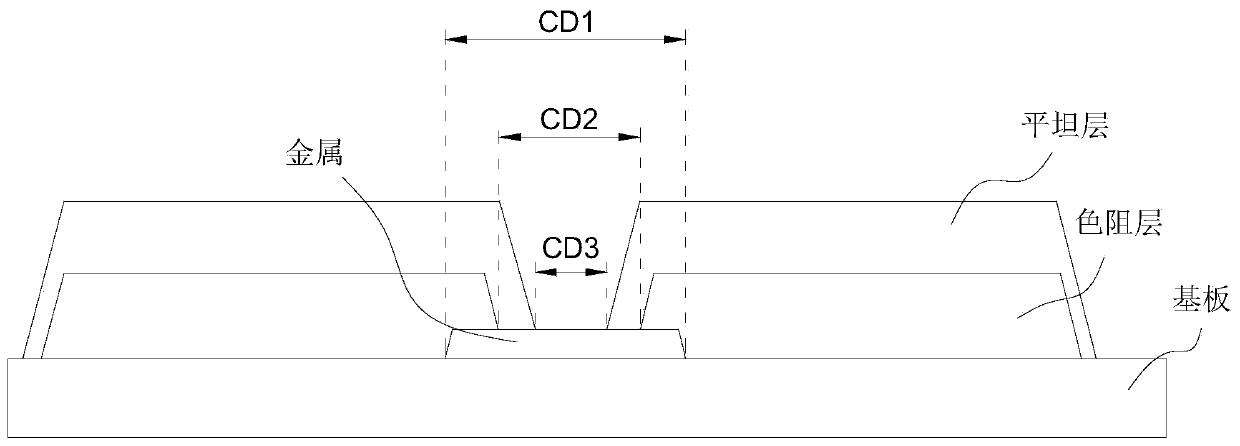

[0058] S6: forming an opening structure on the flat layer, the color resistance layer and the protective layer, the opening structure simultaneously penetrates the flat layer, the color resistance layer and the protective layer and exposes the source and drain metal Floor;

[0059] S7: forming a transparent conductive layer on the planar layer, the transparent conductive layer covers the opening structure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com