Crustal stress prediction method based on actually measured vibration

A prediction method and a technology of ground stress, applied in seismology, measuring devices, geophysical measurements, etc., can solve problems such as low precision and ignoring inclined strata, and achieve the effects of improving precision, wide application range, and accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for predicting the magnitude of ground stress based on measured vibrations, the method comprising the following steps:

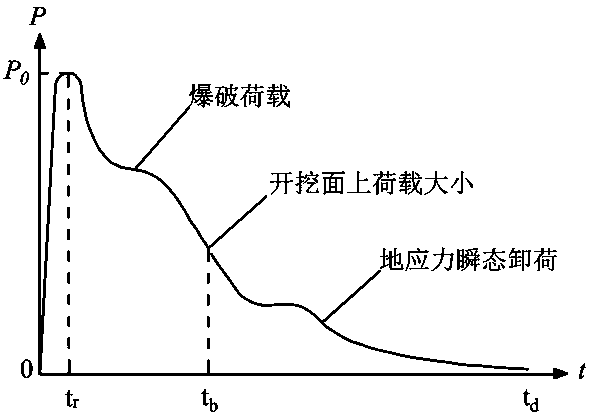

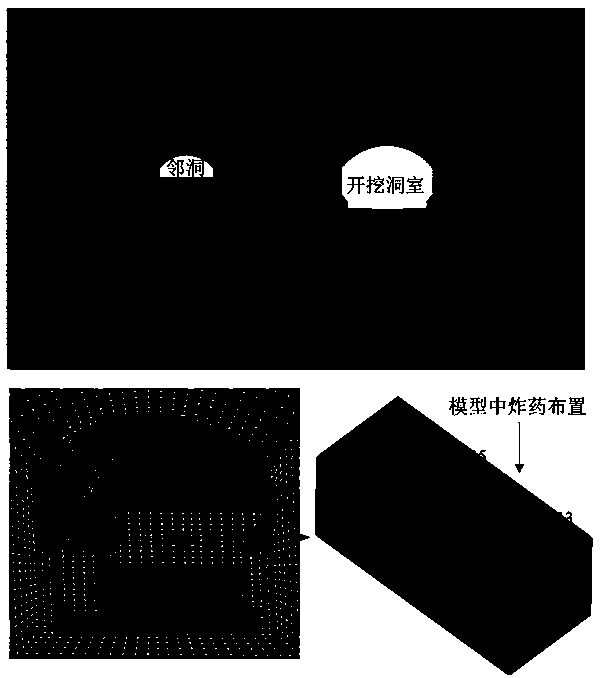

[0058] Step 1: According to blasting design parameters, excavation site environment and selected rock mechanics parameters, establish a circular tunnel blasting excavation analysis model, and obtain the coupling process of ground stress transient unloading and blasting load through theoretical analysis; Step 1 Through theoretical analysis, the coupling process of ground stress transient unloading and blasting load is obtained as follows:

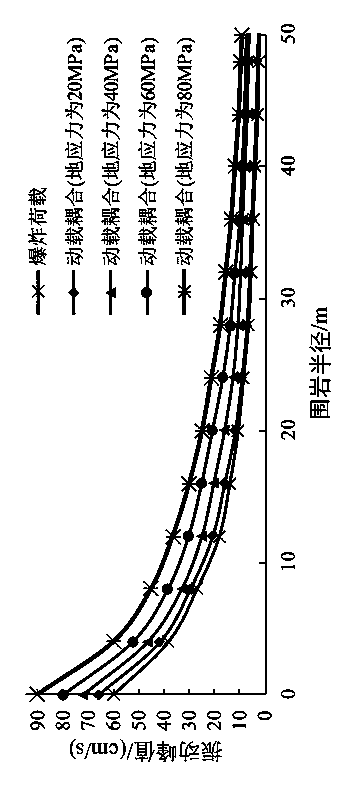

[0059] Starting from the mechanism of blasting load, the state of blasting gas movement, and the mechanical process of transient unloading of ground stress, combined with blasting design parameters and rock mechanical characteristic parameters, the load peak value, pressure change history and continuous Time and the unloading process, start time and duration of the transient unloading of the ground stress, ...

Embodiment 2

[0083]Boreholes are arranged at the excavation site of the tunnel, and the magnitude of the ground stress is measured by hydraulic fracturing. The drill pipe is sent to the selected section to be tested for pressure isolation. After the isolation is completed, water is injected into the section to be tested and pressurized to cause fracturing of the hole wall. stress value. The actual measurement results of the hydraulic fracturing method, the prediction results of the ground stress prediction method based on the measured vibration, and the prediction results of the ground stress prediction method based on the acoustic logging, the comparison of the three is as follows Figure 8 shown. From Figure 8 It can be seen from the figure that the predicted result curve of the method of the present invention is more in line with the measured result curve of the hydraulic fracturing method, while the predicted curve based on the acoustic logging ground stress prediction method is sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com