Anti-radiation flexible cable containing aluminum tape shielding layer for computer and manufacturing method thereof

A technology of aluminum tape shielding and flexible cable, which is used in cable/conductor manufacturing, reducing the size of conductor/cable, insulating cable, etc., to achieve the effects of high transmission performance, good safety performance and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

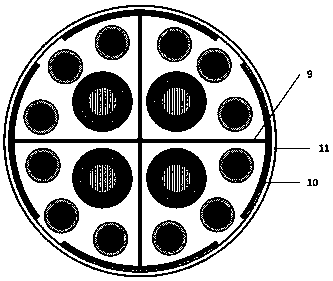

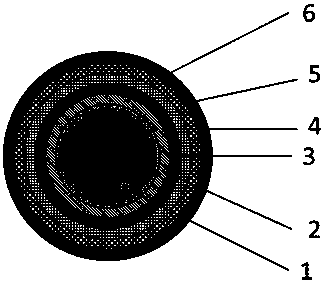

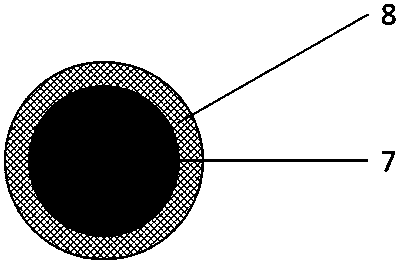

[0035] The cable includes a conductor cable core, a shielded cable core, an aluminum tape shielding layer, and a protective sheath 11. The conductor cable core includes a conductor core 1, and an inner semiconductive shielding layer 2, cross-linked polyethylene Shielding layer 3, outer semi-conductive shielding layer 4, metal shielding layer 5 and sheath 6; shielded cable core includes insulated core 7 and tinned soft copper wire layer 8 braided outside it, and the coverage rate of copper wire layer 8 reaches 70 % or more, the pitch diameter of the shielded cable core is required to be no larger than the conductor cable core; the aluminum tape shielding layer is in the shape of a spoke, and there is a conductor cable core near the center of the shielding layer in the area defined between two adjacent crawler shielding layers. There are several shielded cable cores away from the center of the shielding layer, and the protective sheath 11 wraps the aluminum tape shielding layer o...

Embodiment 2

[0037] The cable includes a conductor cable core, a shielded cable core, an aluminum tape shielding layer, and a protective sheath 11. The conductor cable core includes a conductor core 1, and an inner semiconductive shielding layer 2, cross-linked polyethylene Shielding layer 3, outer semi-conductive shielding layer 4, metal shielding layer 5 and sheath 6; shielded cable core includes insulated core 7 and tinned soft copper wire layer 8 braided outside it, and the coverage rate of copper wire layer 8 reaches 70 % or more, the pitch diameter of the shielded cable core is required to be no larger than the conductor cable core; the aluminum tape shielding layer is in the shape of a spoke, and there is a conductor cable core near the center of the shielding layer in the area defined between two adjacent crawler shielding layers. There are several shielded cable cores away from the center of the shielding layer. The protective sheath 11 is wrapped on the outside of the aluminum tap...

Embodiment 3

[0039] The cable includes a conductor cable core, a shielded cable core, an aluminum tape shielding layer, and a protective sheath 11. The conductor cable core includes a conductor core 1, and an inner semiconductive shielding layer 2, cross-linked polyethylene Shielding layer 3, outer semi-conductive shielding layer 4, metal shielding layer 5 and sheath 6; shielded cable core includes insulated core 7 and tinned soft copper wire layer 8 braided outside it, and the coverage rate of copper wire layer 8 reaches 70 % or more, the pitch diameter of the shielded cable core is required to be no larger than the conductor cable core; the aluminum tape shielding layer is in the shape of a spoke, and there is a conductor cable core near the center of the shielding layer in the area defined between two adjacent crawler shielding layers. There are several shielded cable cores away from the center of the shielding layer, the protective sheath 11 is wrapped outside the aluminum tape shieldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com