Photovoltaic module based on diffractive optical element and manufacturing method thereof

A diffractive optical element and photovoltaic module technology, applied in photovoltaic modules, electrical components, photovoltaic power generation, etc., can solve the problems of photoelectric current consumption, waste of chip raw materials to increase costs, and affect the photoelectric conversion efficiency of gallium arsenide chips, etc., to achieve a reasonable structure , Improve stability, improve the effect of photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

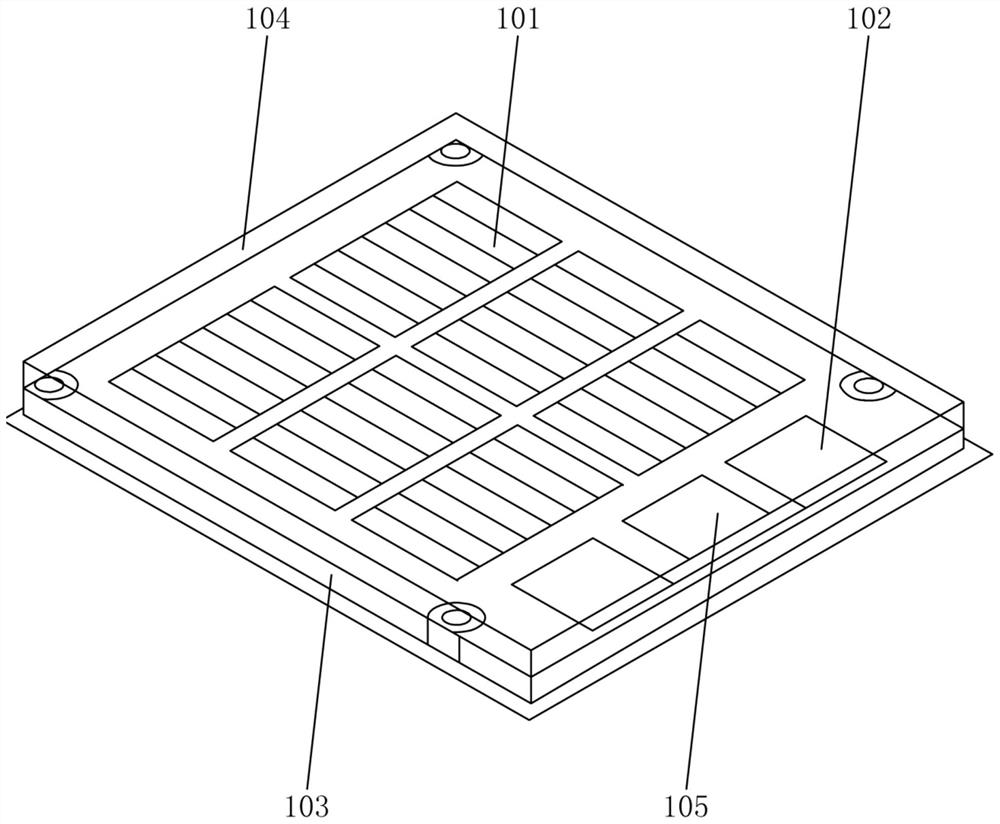

[0023] Such as figure 1 As shown, a photovoltaic module based on a diffractive optical element according to the present invention includes a heat-conducting substrate 103, on which a plurality of gallium arsenide chips 101 are arranged, and a plurality of gallium arsenide chips 101 are sequentially connected in series to form a conversion module, And the conversion module is covered with a diffractive optical element 104; the heat-conducting substrate 103 is provided with the positive and negative terminals 102 of the conversion module; the conversion module composed of several gallium arsenide chips 101 can perform laser light energy Efficient conversion, the diffractive optical element 104 is used to replace the traditional glass cover, the diffractive optical element 104 can scatter the laser light so that the gallium arsenide chip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com