Battery core tab calibration device

A calibration device and tab technology, applied to circuits, electrical components, assembled battery machines, etc., can solve problems such as bad operation, tab bending deformation, and tabs not being able to pass through busbar holes, so as to achieve no safety hazards and improve Bad and Reworked Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

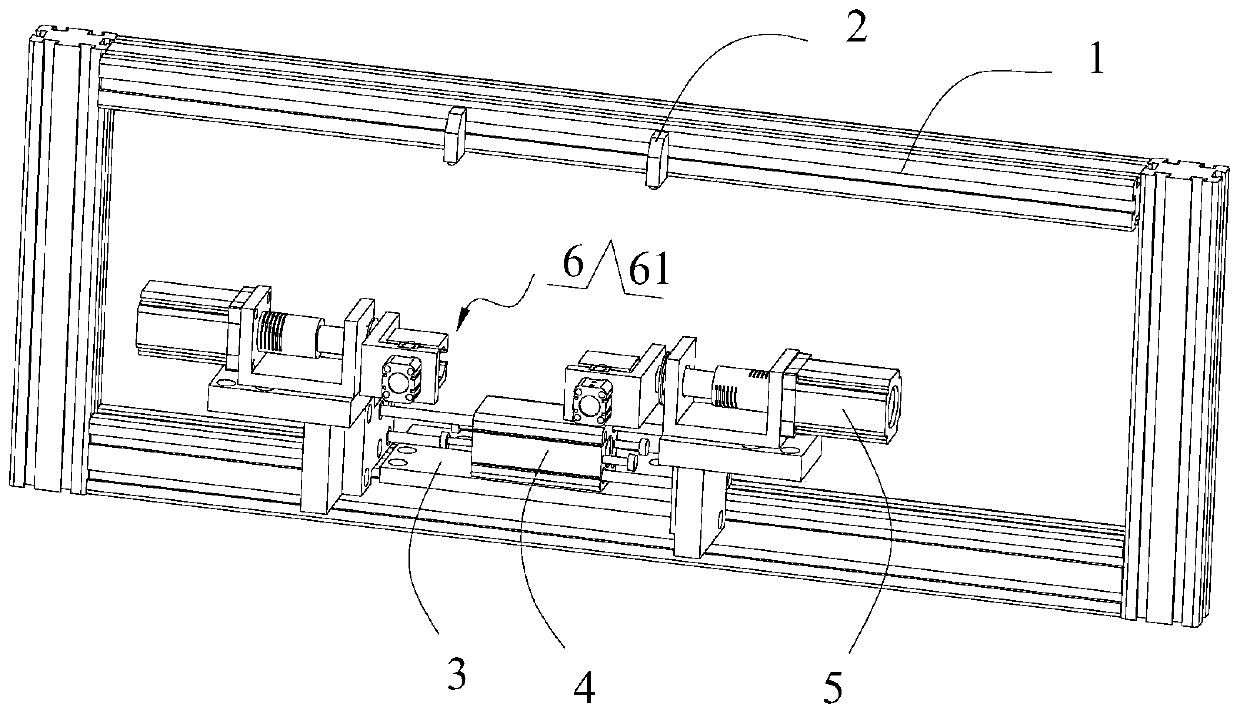

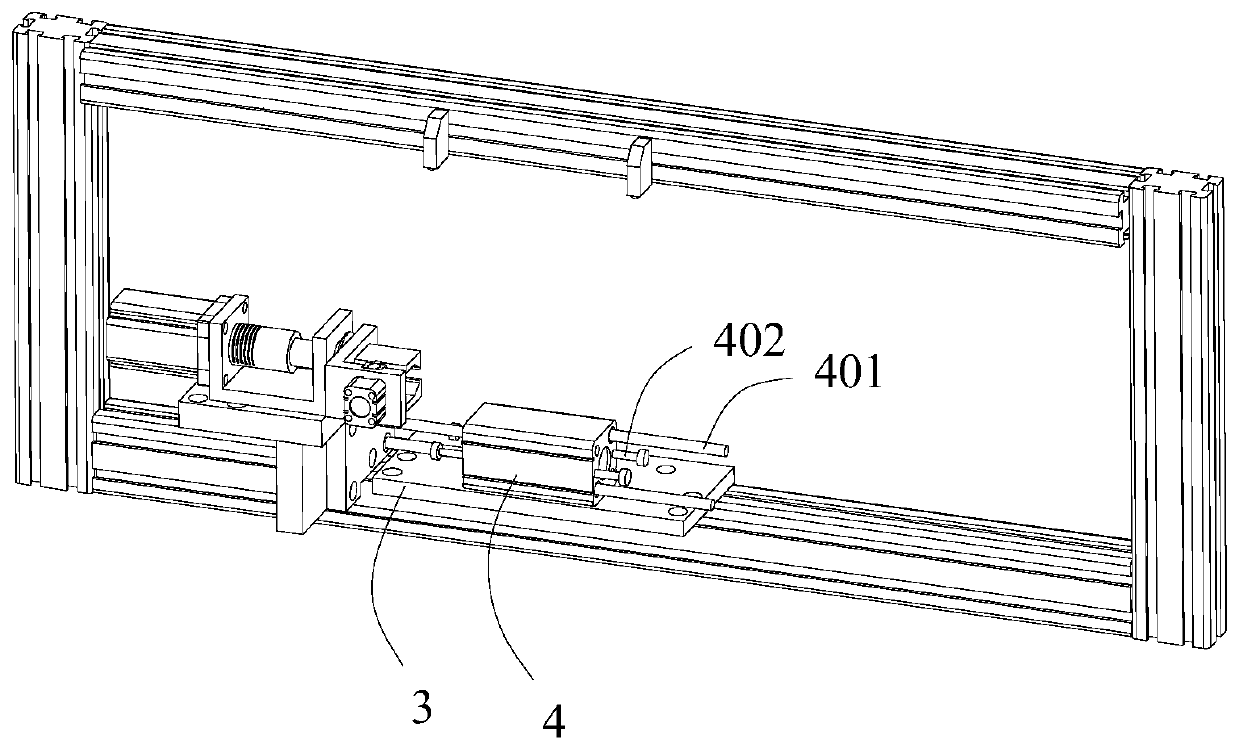

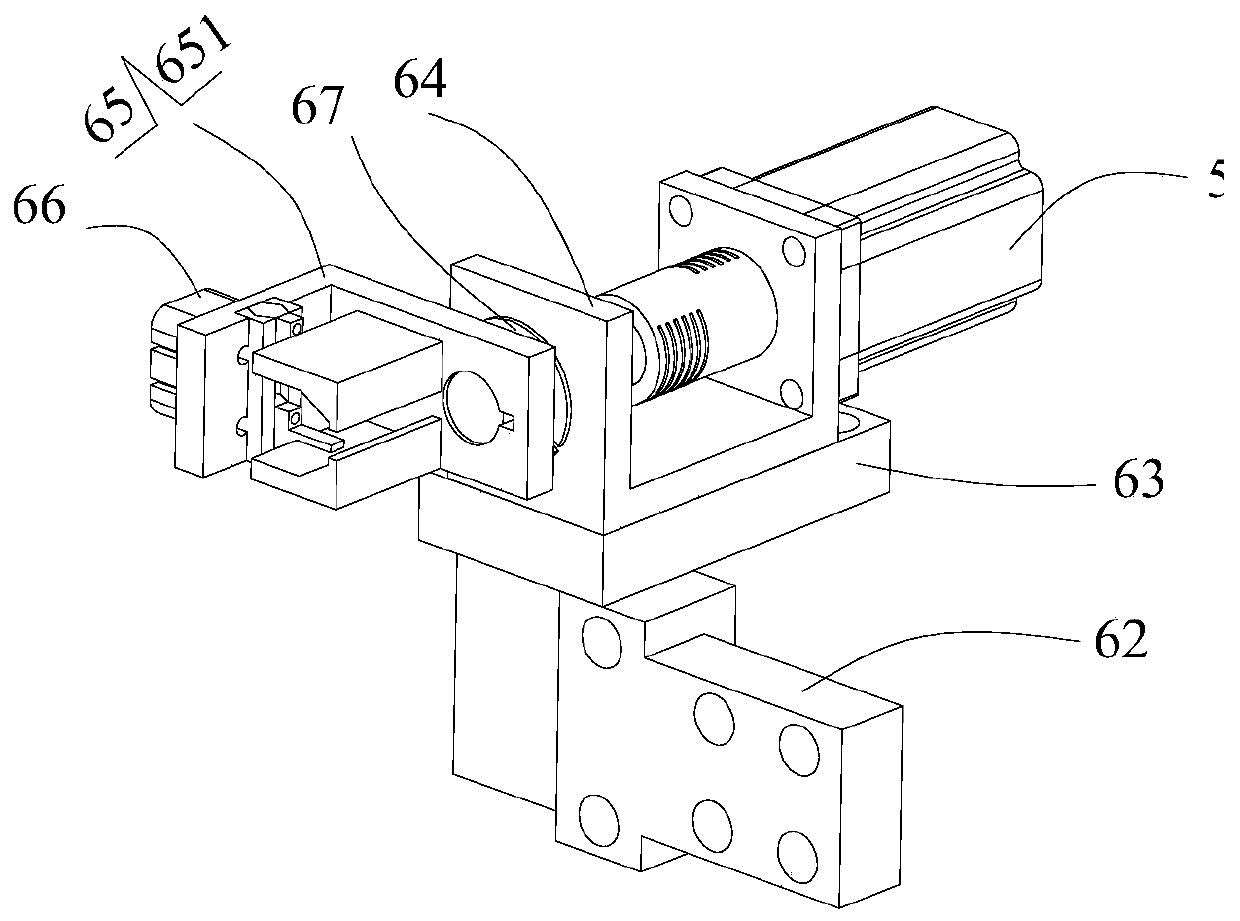

[0022] refer to Figure 1-4 As shown, the present invention provides a battery lug calibration device, including: a bracket 1, and two CCD detectors 2 installed on the bracket 1, a base plate 3, a width adjustment cylinder 4, and two stepping motors 5 and two clip assemblies 6, the width adjustment cylinder 4 is arranged on the base plate 3 to adjust the distance between the two clip assemblies 6; the CCD detector 2 is used to detect the deformation data of the battery tab; each clip assembly 6 includes A pair of mechanical clips 61, each stepping motor 5 is used to adjust the angle of the mechanical clips 61 to perform tab correction according to the detected deformation data of the tabs of the battery core.

[0023] As a preferred embodiment of the present invention, two CCD detectors 2 are arranged in the middle of the top of the support 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com