Lithium battery negative electrode slurry dry preparation method

A negative electrode slurry and preparation method technology, which is applied in the field of dry preparation of lithium battery negative electrode slurry, can solve the problems of lower production costs, poor electrode pieces, poor stirring effect, etc., and achieve the effect of reducing preparation time and usage amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The stirring equipment used in this embodiment is Guangzhou Hongyun 300L double planetary mixer.

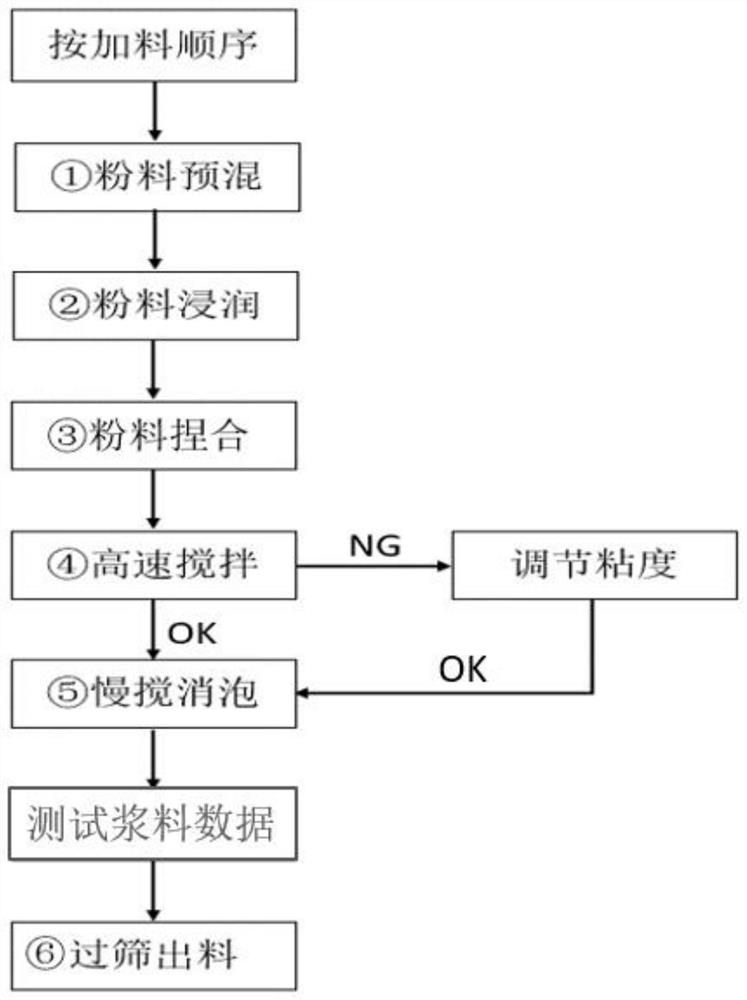

[0029] The dry preparation method of lithium battery negative electrode slurry of the present invention comprises the following steps:

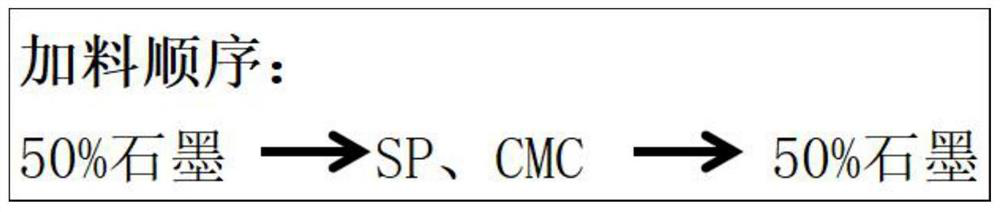

[0030] (1) Powder premixing: such as figure 1 Shown is the sequence diagram of powder feeding. According to the process addition amount, add 50% graphite, conductive carbon black (SP) and sodium carboxymethyl cellulose (CMC), and 50% graphite into the mixing tank of the mixer in sequence, and mix the mixing tank and Close the mixer, turn on the stirring and dispersing mode of the mixer, set the stirring speed to 20rpm, and the dispersion speed to 500rpm before premixing without vacuum; this step is to mix all kinds of powder materials evenly, and observe the state of the powder materials in the mixer through the window of the mixer during the mixing process , whether there is dust, you can fine-tune the speed of the mixer according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com