A spliced flat motor mover structure

A flat-panel motor, splicing technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of continuous thrust, small peak thrust, small linear motor thrust, and large linear motor thrust, and achieves easy assembly and splicing. The effect of space and material cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

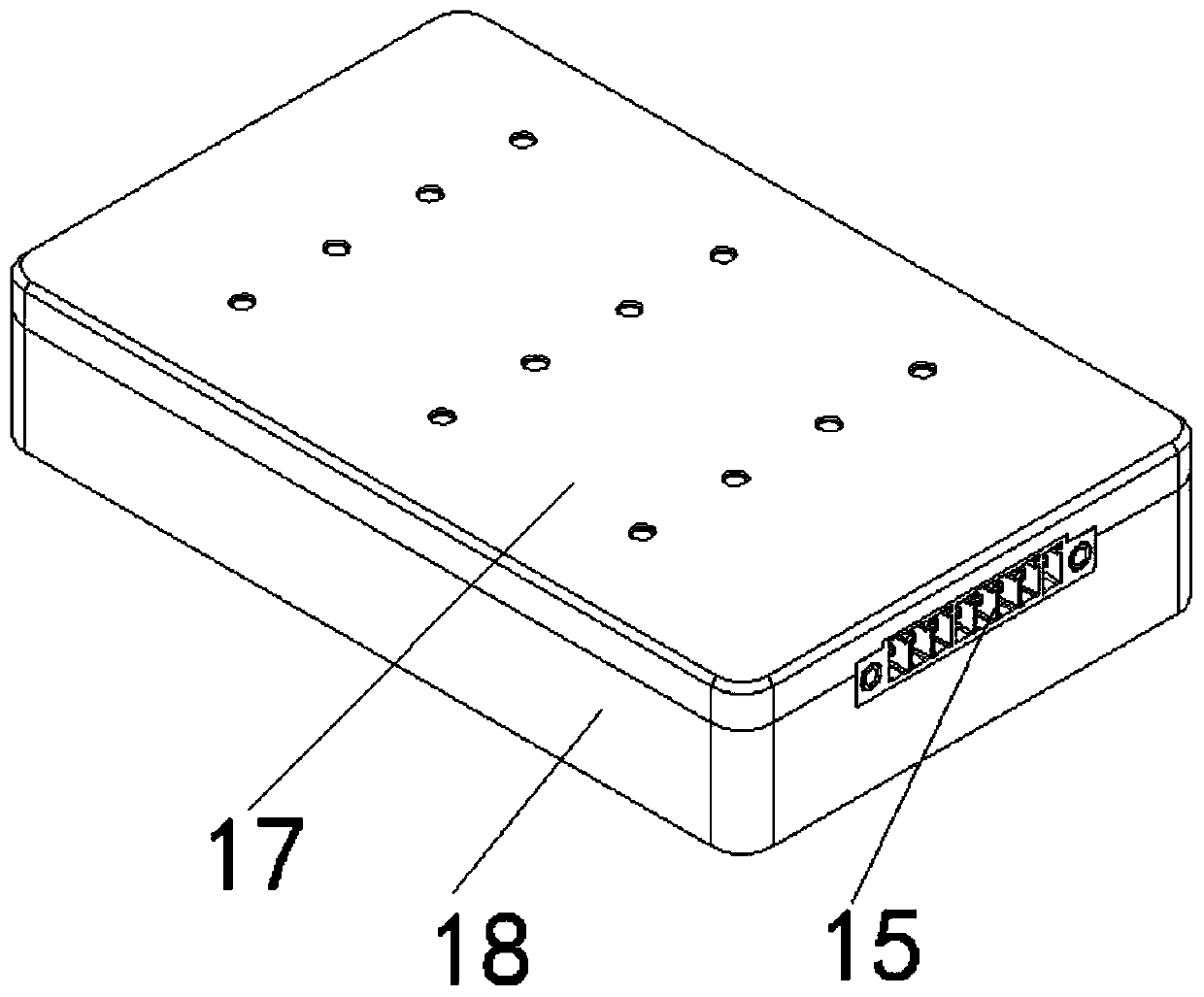

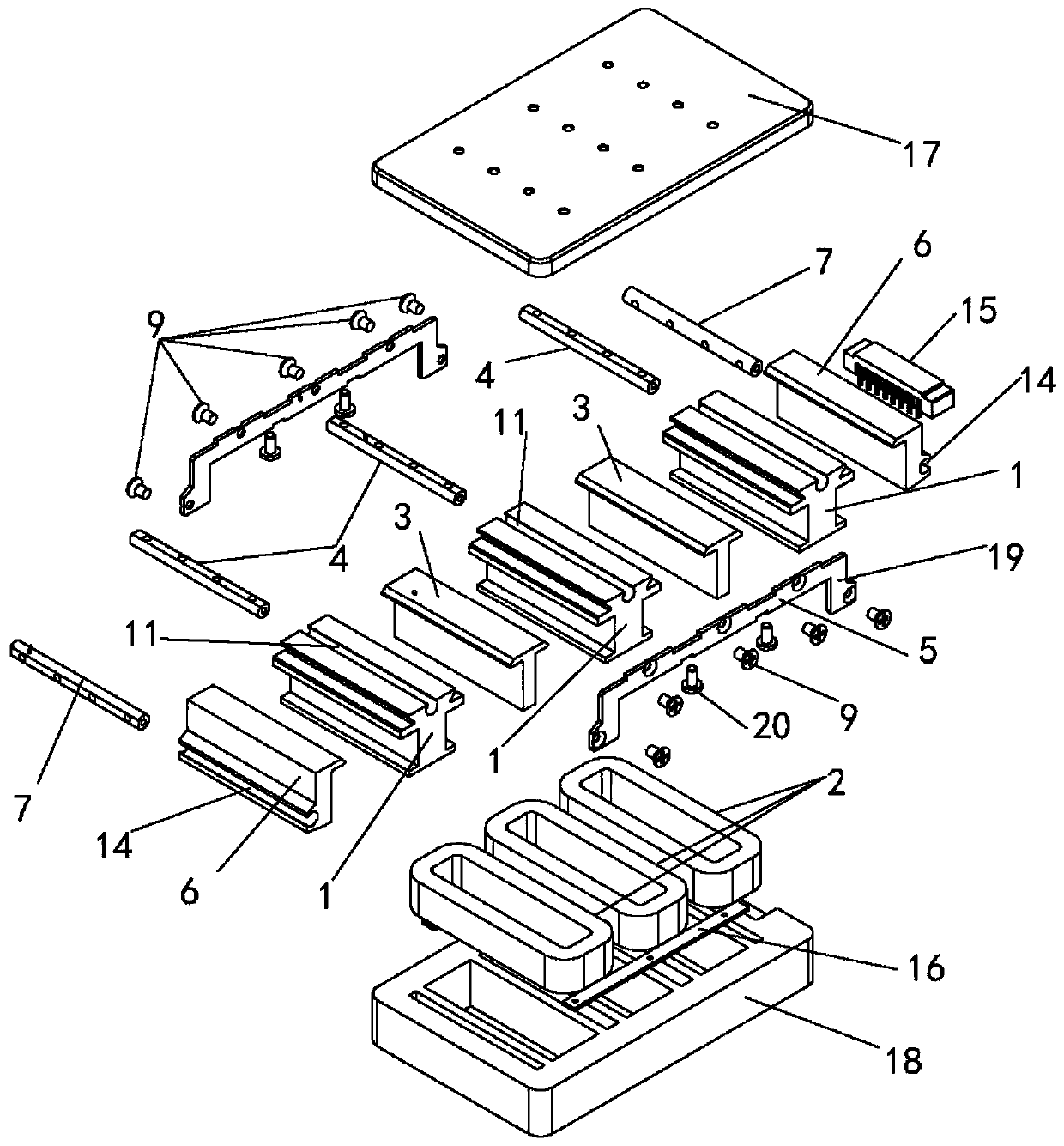

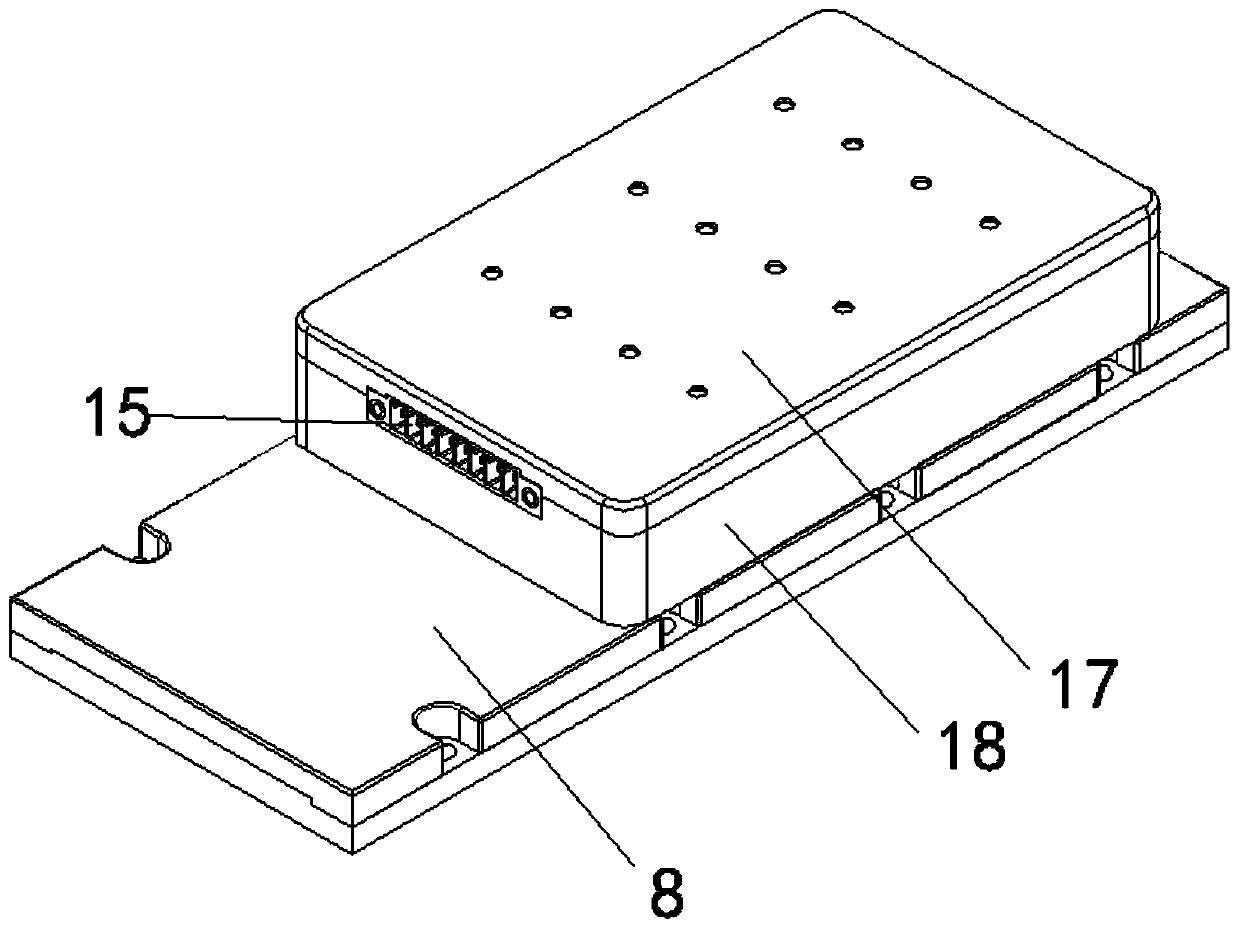

[0027] like Figure 1 to Figure 8 As shown, a spliced flat motor mover structure includes a plurality of independent spliced wound cores 1 and coils 2, and spliced middle cores 3 are arranged between every two spliced wound cores 1. The two ends of each spliced winding iron core 1 are respectively connected with iron core splints 5 through a fixing strip 4, and the iron core 3 in the splicing is clamped between two spliced winding iron cores 1, and the coil 2 is directly wound. Formed on the spliced wound iron core 1. The coil 2 is directly wound around the groove of the spliced winding iron core 1 which is an I-shaped groove 10, making full use of the slot filling rate between the iron core and the coil 2, so as to achieve the best performance of the motor. The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com