High-efficiency coagulant preparation system and process

A technology for preparing a system and a coagulant, which is applied in the direction of grain processing, etc., can solve the problems of unsatisfactory coagulation effect and many impurities in coagulant, and achieve the effect of good coagulation effect, less impurities and low fineness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the application clearer, the embodiments of the application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

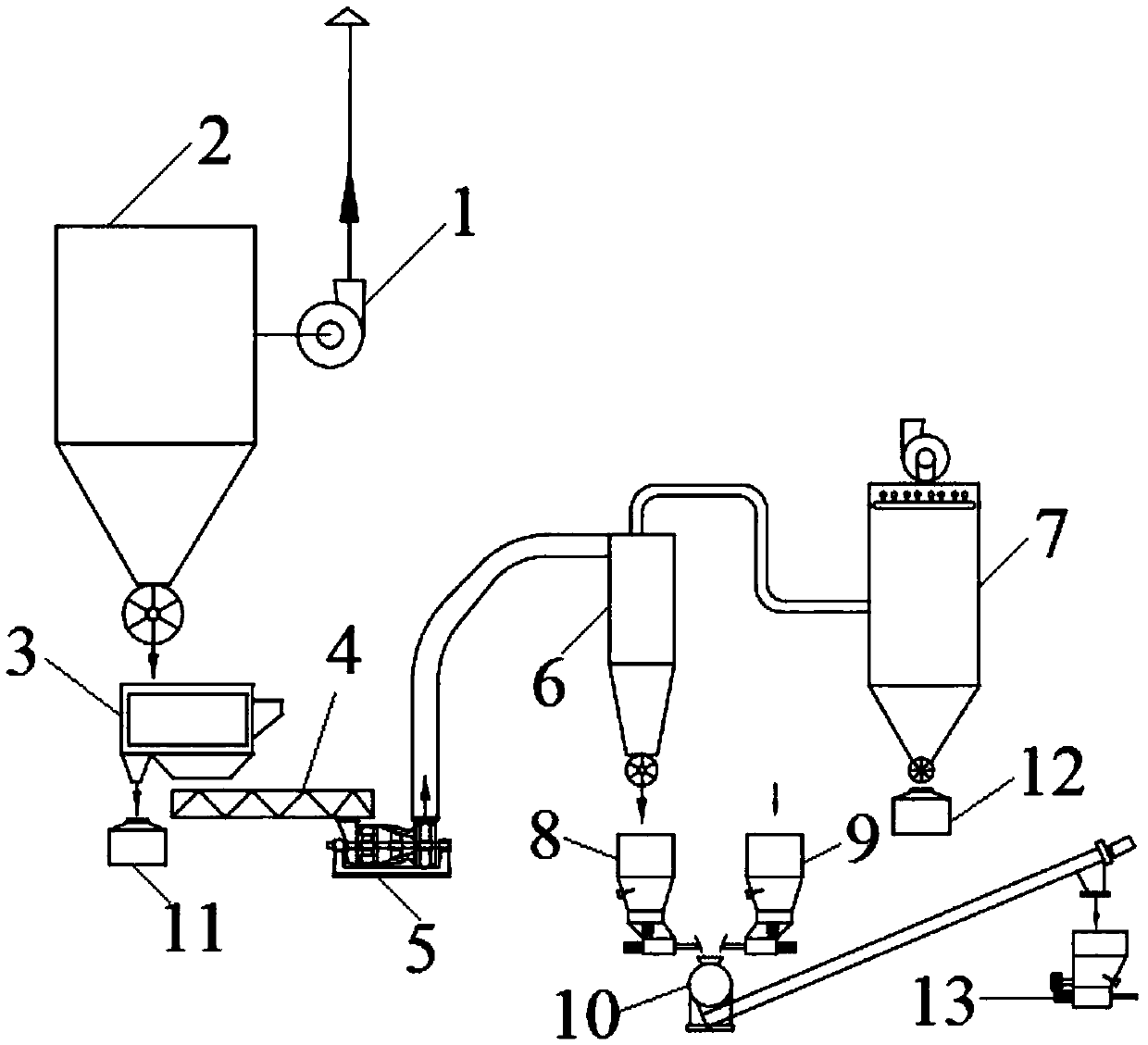

[0031] The embodiment of the present application provides a high-efficiency coagulant preparation system, the system includes: dust collection fan 1, first bag filter 2, rotary screen 3, first conveyor 4, pulverizer 5, cyclone separator 6 , the second bag filter 7, the second conveyor 8, the third conveyor 9 and the ball mill 10, the first bag filter 2 is used to collect gypsum board trimmings with the assistance of the dust collection fan 1, The outlet of the first bag filter 2 is connected to the inlet of the rotary screen 3, and the rotary screen 3 is used to remove large pieces of paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com