Three-pin fork machining process

A three-pin shaft fork and processing technology, which is applied in the field of three-pin shaft fork processing technology, can solve the problems affecting the precision of the transmission shaft and dimensional deviation, and achieve the effects of convenient operation, avoiding dimensional deviation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

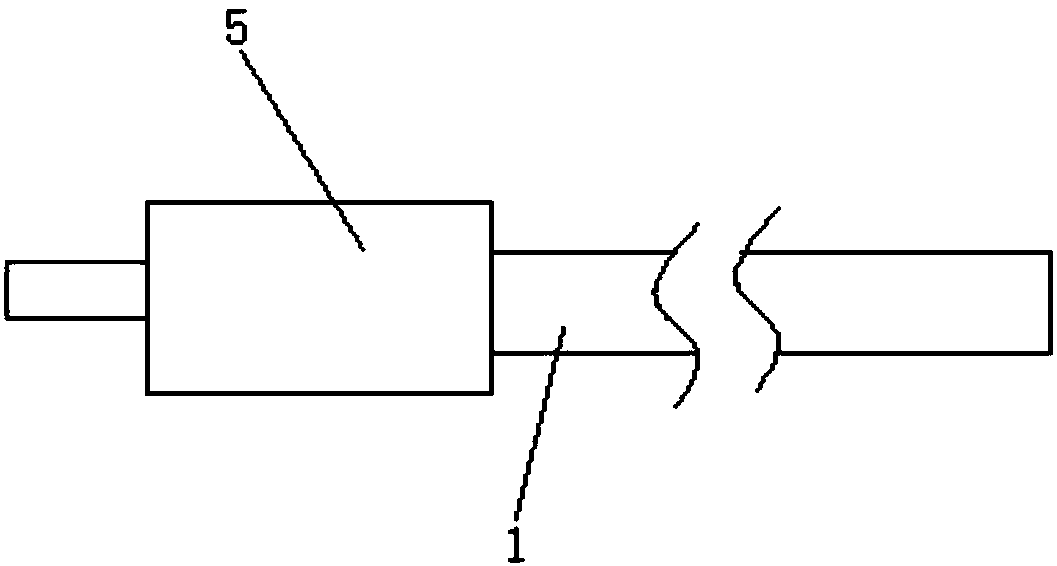

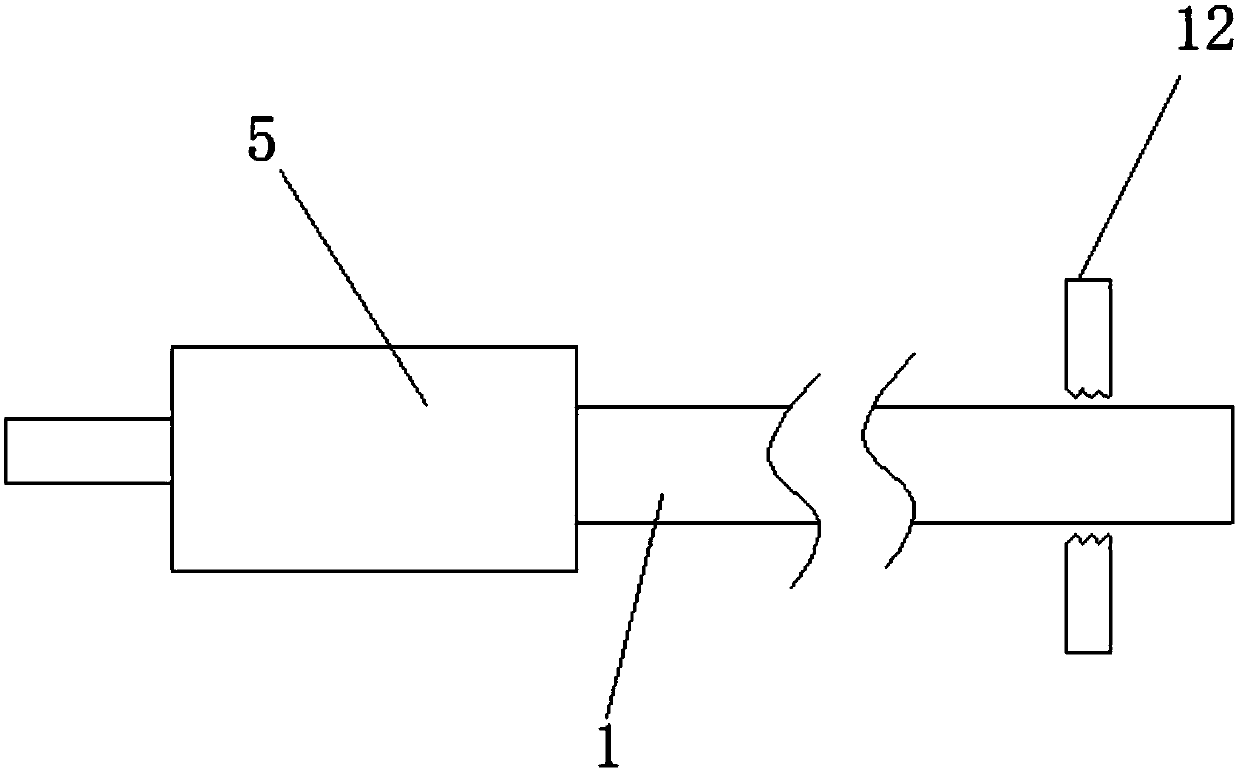

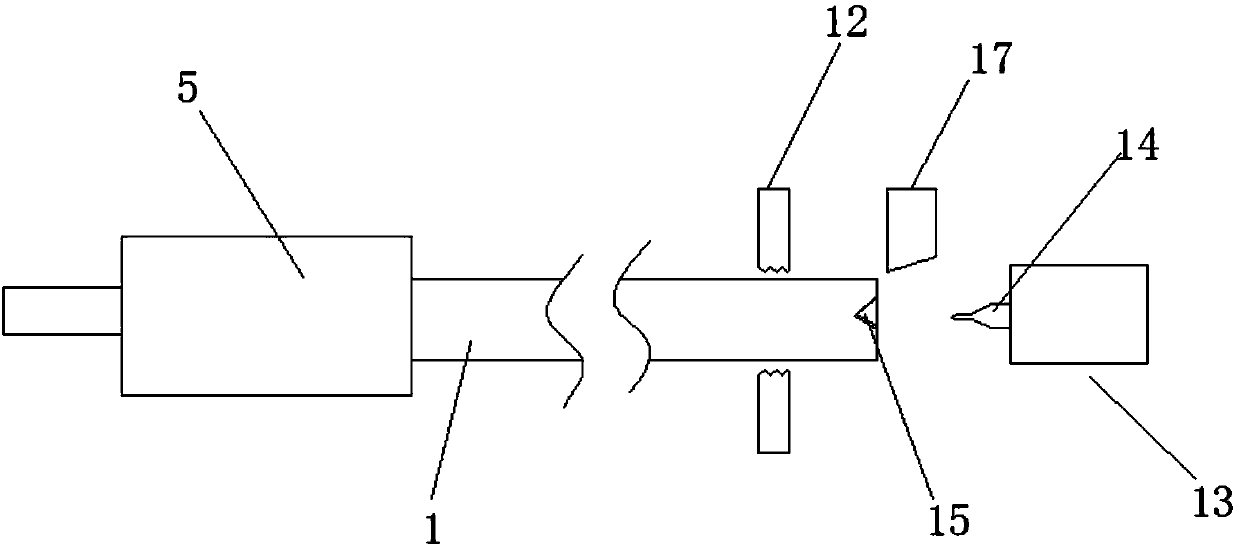

[0031] Such as Image 6 , 7 , The three-pin shaft fork 1 includes a ball portion 3 provided with a ball way 2 and a handle portion 4 connected with the ball portion 3. The positioning tool 5 includes a receiving portion 7 with a receiving cavity 6 and a clamping portion 8 integrally arranged on the receiving portion 7. The clamping portion 8 is coaxial with the receiving portion 7, and the receiving cavity 6 is provided with a three-pin shaft fork 1 Cooperating transmission mechanism, the transmission mechanism includes a central column 9, three transmission blocks 10 are arranged outside the central column 9, the angle between adjacent transmission blocks 10 is 120°, the inner wall of the containing cavity 6 is provided with three positioning ribs 11, positioning ribs 11 Integrated with the containing cavity 6, the angle between adjacent positioning ribs 11 is 120°

[0032] The three-pin shaft fork 1 extends into the containing cavity 6, and the positioning rib 11 corrects the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com