Auxiliary forming device for automobile side guardrails

An automobile side and auxiliary forming technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as difficult horizontal placement of beams, poor product consistency, and unfavorable assembly efficiency, so as to improve working strength and size The effect of strong stability, improved efficiency and product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

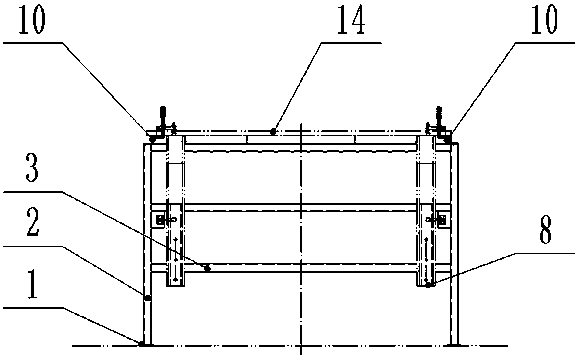

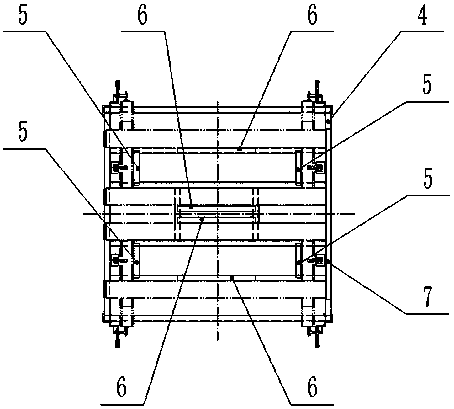

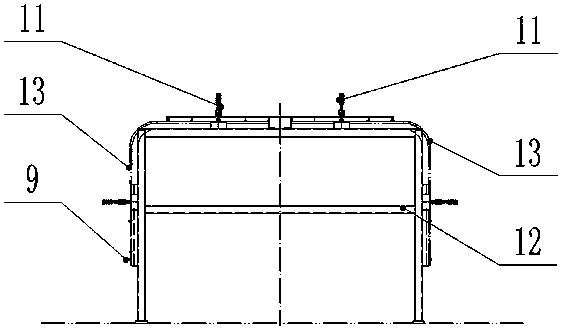

[0019] Now, the technical solutions in the embodiments of the present invention will be clearly and completely described in conjunction with the accompanying drawings. This figure is a simplified schematic diagram and only schematically illustrates the basic structure of the present invention.

[0020] according to figure 1 , 2 , 3, 4, and 5, on the backing plate 1, a column 2 is vertically fixedly connected, and on the column 2, a crossbeam 3, a longitudinal beam 12, and a first connecting beam 4 are connected, and a second connecting beam 4 is arranged on the first connecting beam 4. Connecting beam 15, on the second connecting beam 15 and crossbeam 3 there are longitudinal positioning plate 6 and transverse positioning plate 5, end positioning 7 is arranged on the first connecting beam 4, positioning seat 8 and positioning pin 9 are arranged on crossbeam 3; There is a supporting seat 10 on the connecting beam 4 and the column 2, and a quick clamp 11 is arranged thereon. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com