Stereoscopic printing device

A three-dimensional printing and packaging technology, which is applied in the direction of processing drive devices, transportation and packaging, and processing accessories of main materials, etc., can solve problems such as curing and affecting progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used in the drawings and description to refer to the same or like parts.

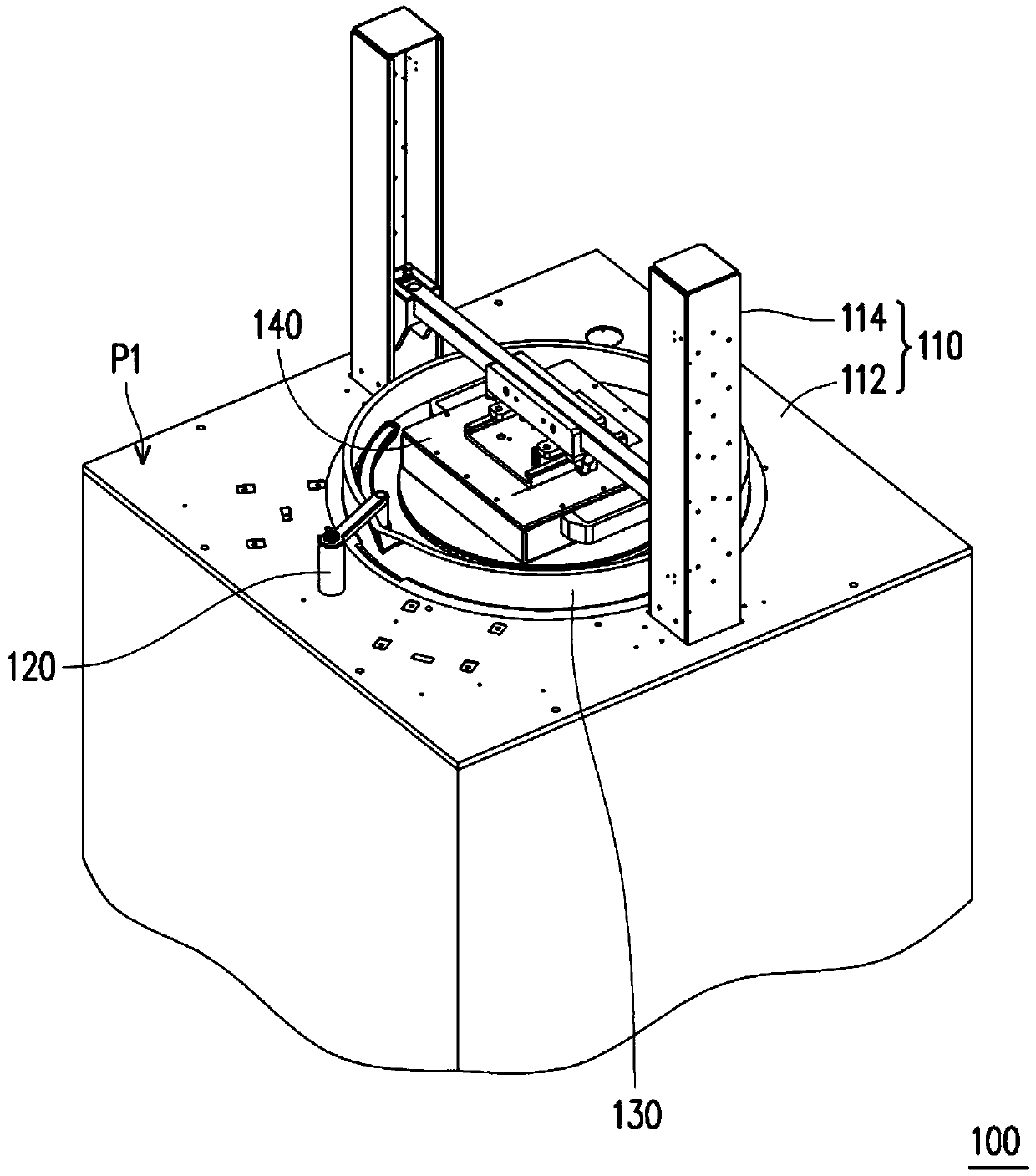

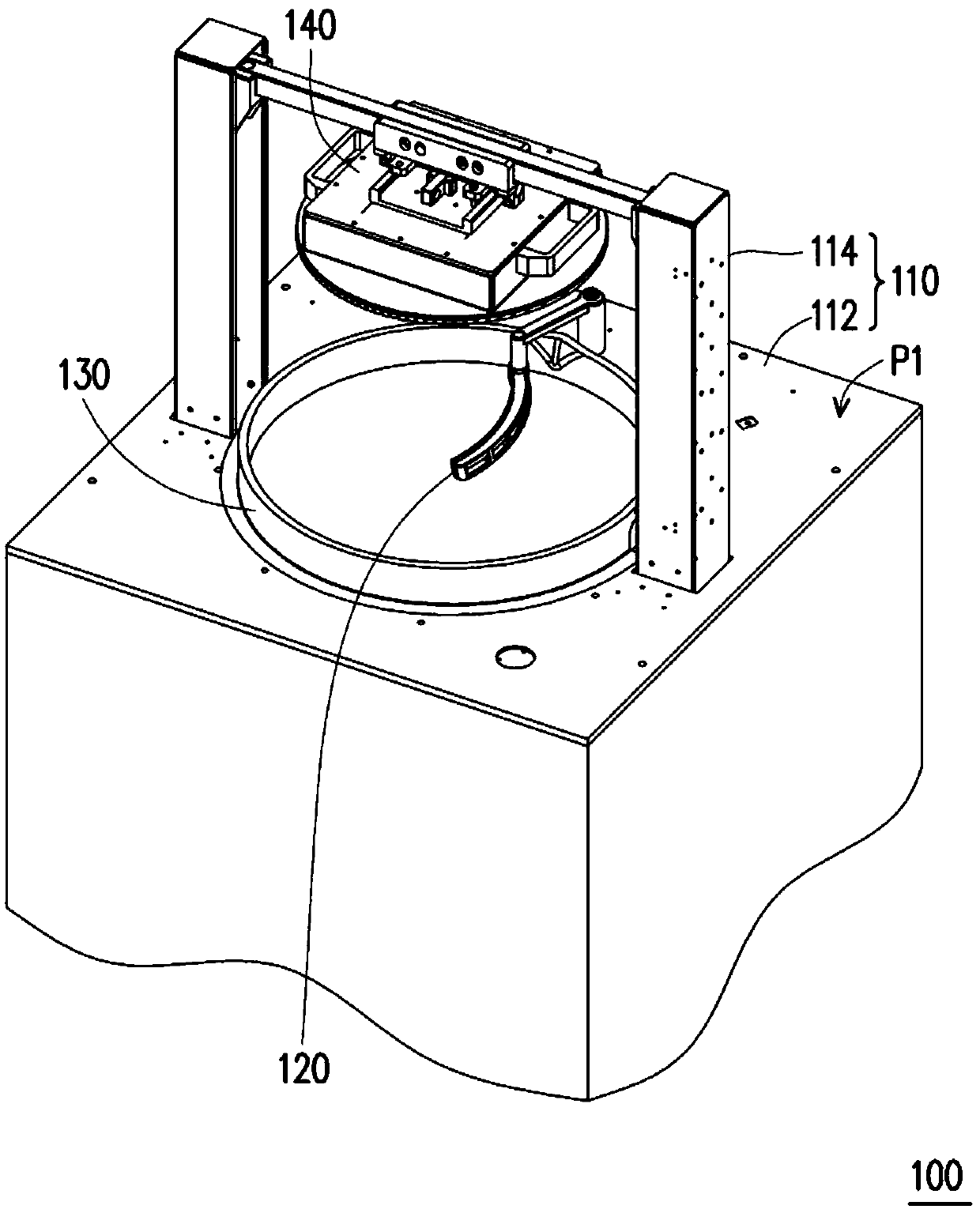

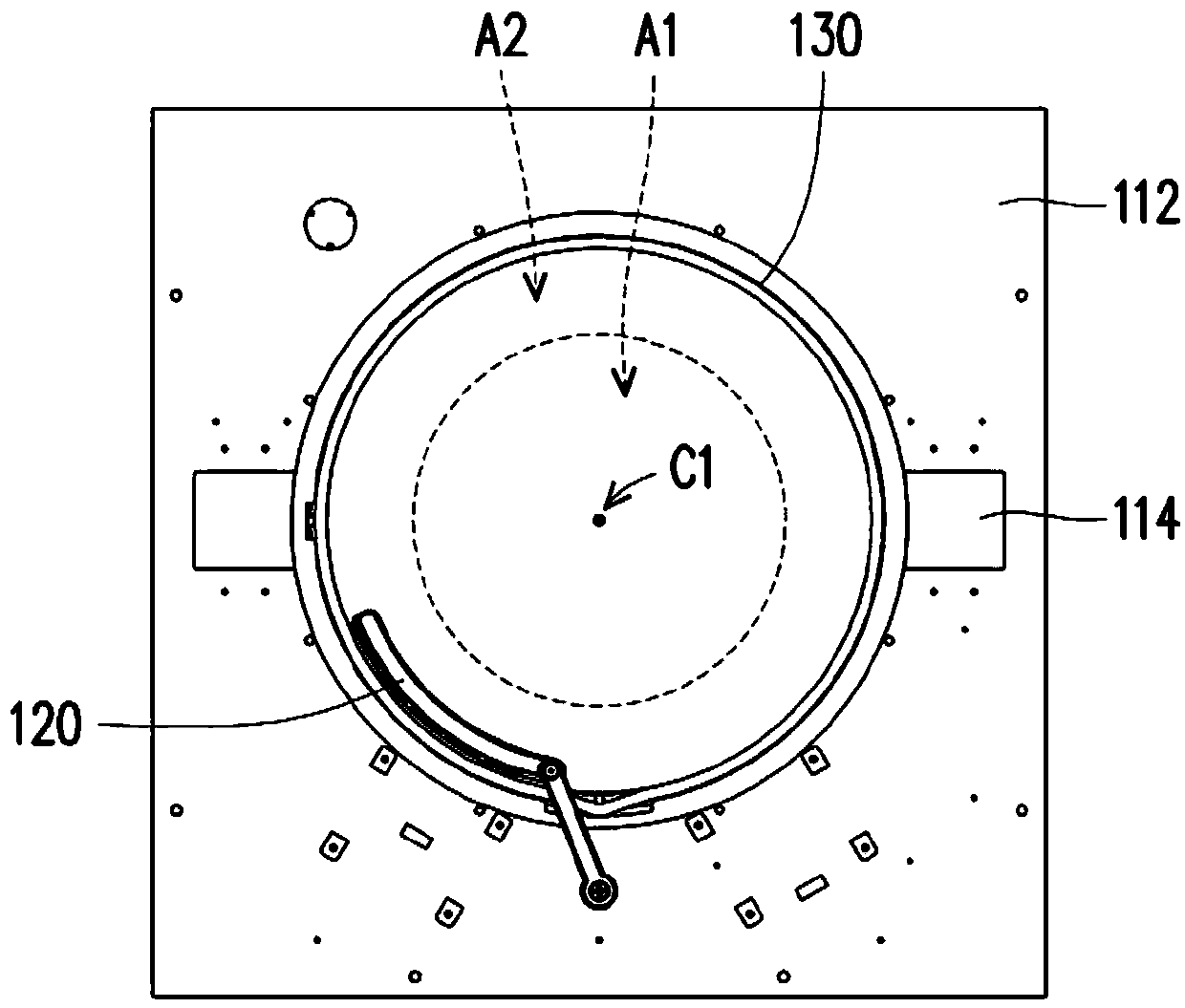

[0040] figure 1 is a schematic diagram of a three-dimensional printing device according to an embodiment of the present invention. figure 2 Yes figure 1 The schematic diagram of the 3D printing device in another state. image 3 and Figure 4 They are top views of the three-dimensional printing device in different states. Figure 5 It is a schematic diagram of the electrical connection of the relevant components of the three-dimensional printing device. Please refer to figure 1 and Figure 5 , in this embodiment, the three-dimensional printing device 100, such as a three-dimensional lithography device, includes a machine 110, an agitating member 120, a tank 130, a forming platform 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com