Flat plate flow cavity capable of simultaneously applying static pulling force and flow shearing force

A flat-plate flow chamber and shear force technology, which is applied in the field of flat-plate flow chambers, can solve the problems of reducing flow stability, expanding the cavity structure, and hindering various stimulation stresses, so as to improve the operation stability, improve the simulation effect, and reduce the The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

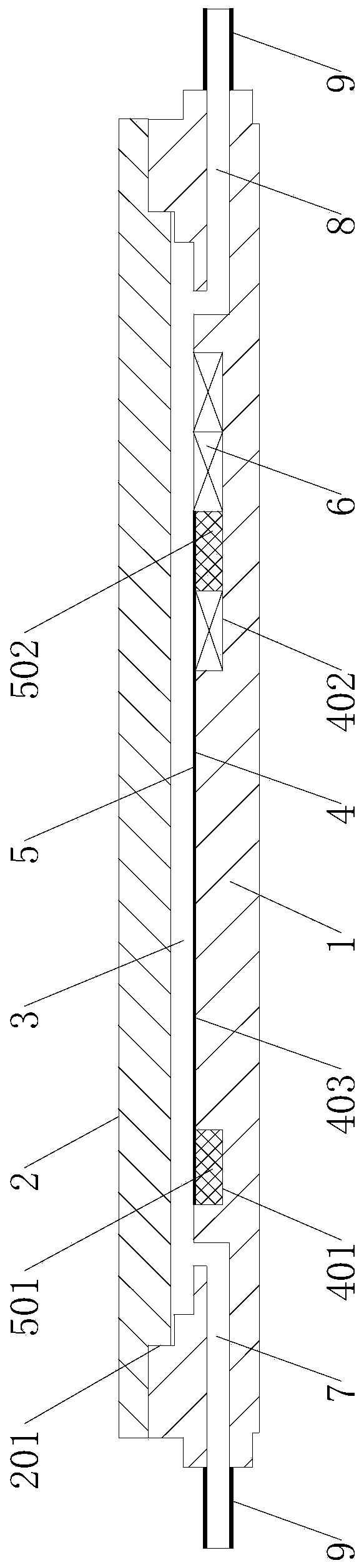

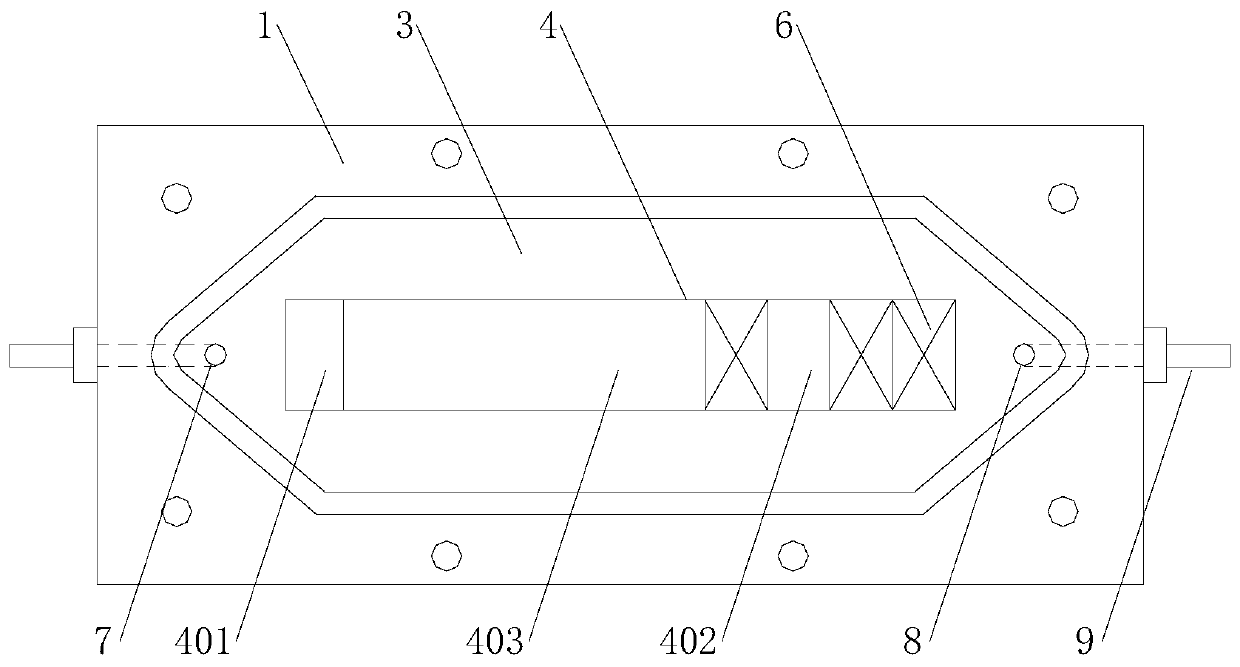

[0029] Example. A flat plate flow chamber that simultaneously applies static tension and flow shear, constituted as figure 1 As shown, it includes a base 1 and a cover plate 2 connected to each other. The base 1 is provided with a flow chamber groove 3, the bottom of the flow chamber groove 3 is provided with a placement groove 4, and the two ends of the placement groove 4 are respectively provided with a fixing groove 401 and a cover plate 2. The chute 402 is provided with a flexible film 5 in the placement groove 4, and one end of the flexible film 5 is provided with a first clip 501 buckled into the fixing groove 401, and the other end of the flexible film 5 is provided with a second clip snapped into the chute 402. The feet 502 , and a plurality of sliding blocks 6 are arranged in the sliding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com