Sandy soil embankment construction method

A construction method and sandy soil technology, applied in botany equipment and methods, construction, water conservancy projects, etc., can solve problems such as poor anti-scouring performance, poor viscosity, and poor stability of dike body, so as to increase anti-seepage performance, increase Stability, increase the effect of erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

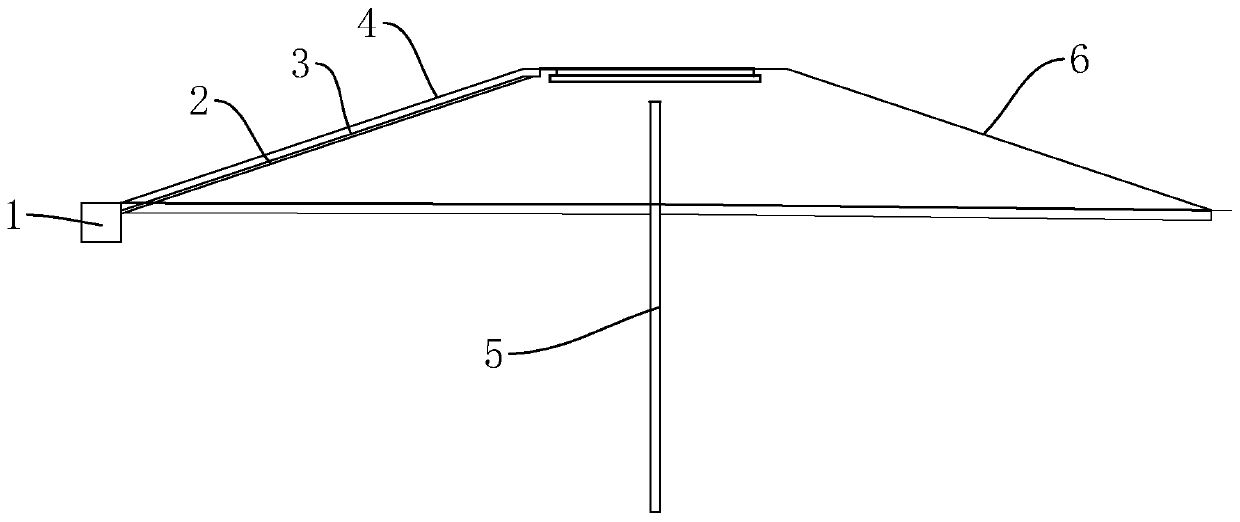

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] refer to figure 1 , is a kind of sandy soil embankment construction method disclosed by the present invention, comprises the following steps:

[0038] S1. Cleaning base: remove turf humus soil and other sundries on the original ground at the bottom of the embankment. The average thickness of base cleaning is 30cm. For weak interlayer geology such as organic soil and silt that still exist after foundation clearing, it needs to be removed to expose the dense soil layer.

[0039] S2. Filling: filling and rolling the sandy soil in layers and sections. First divide the filling area into sections, and set up signs in each section to prevent leakage, underpressure and overpressure in subsequent vibrating mills. Fill each section of the filling area layer by layer. The thickness of each layer of filling is 30cm. When filling, follow the rule of filling laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com