Rustproof construction process of steel structure building using structural steel beams coated with steel beam permanent formwork pouring concrete

A construction process, formwork-free technology, applied in building components, building structures, buildings, etc., can solve the problems of difficult rust-proof treatment of exposed steel components, difficult construction, and complicated processes, so as to shorten the construction period and simplify the construction. Process, improve the effect of labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that these embodiments are for illustration purposes only, and in no way limit the protection scope of the present invention. For the experimental methods that do not specify specific conditions in the examples, usually follow the conventional conditions or the conditions suggested by the manufacturer.

[0026] Concrete construction technology of the present invention is:

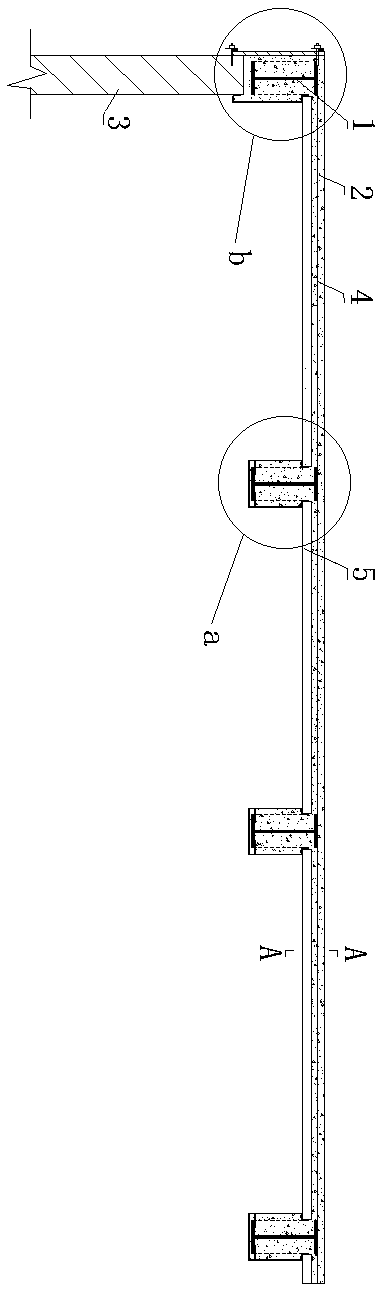

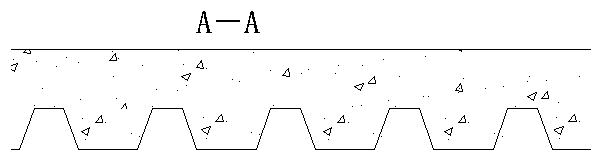

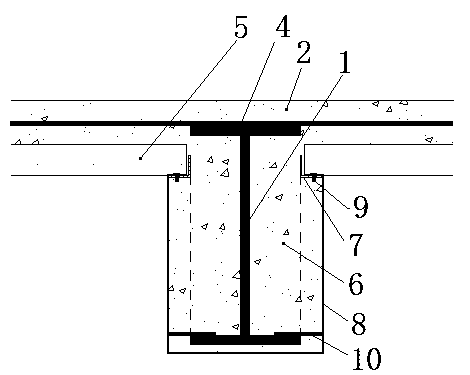

[0027] 1. Structural steel beam installation: According to the design requirements, the steel beams and other components that have been transported to the construction site and have been fabricated are assembled and installed in place according to the requirements of the construction drawings. After the bolts are fastened, they are welded and fixed firmly. For details, see figure 1 ;

[0028] 2. Fixing of formwork angle steel: The formwork angle stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com