Aluminum alloy formwork high and large formwork erecting system and mounting method thereof

A technology of aluminum alloy formwork and aluminum formwork, which is applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connection parts, pillars, etc. Resource waste and other problems, to achieve the effect of convenient disassembly and transfer, widening the scope of adjustment, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

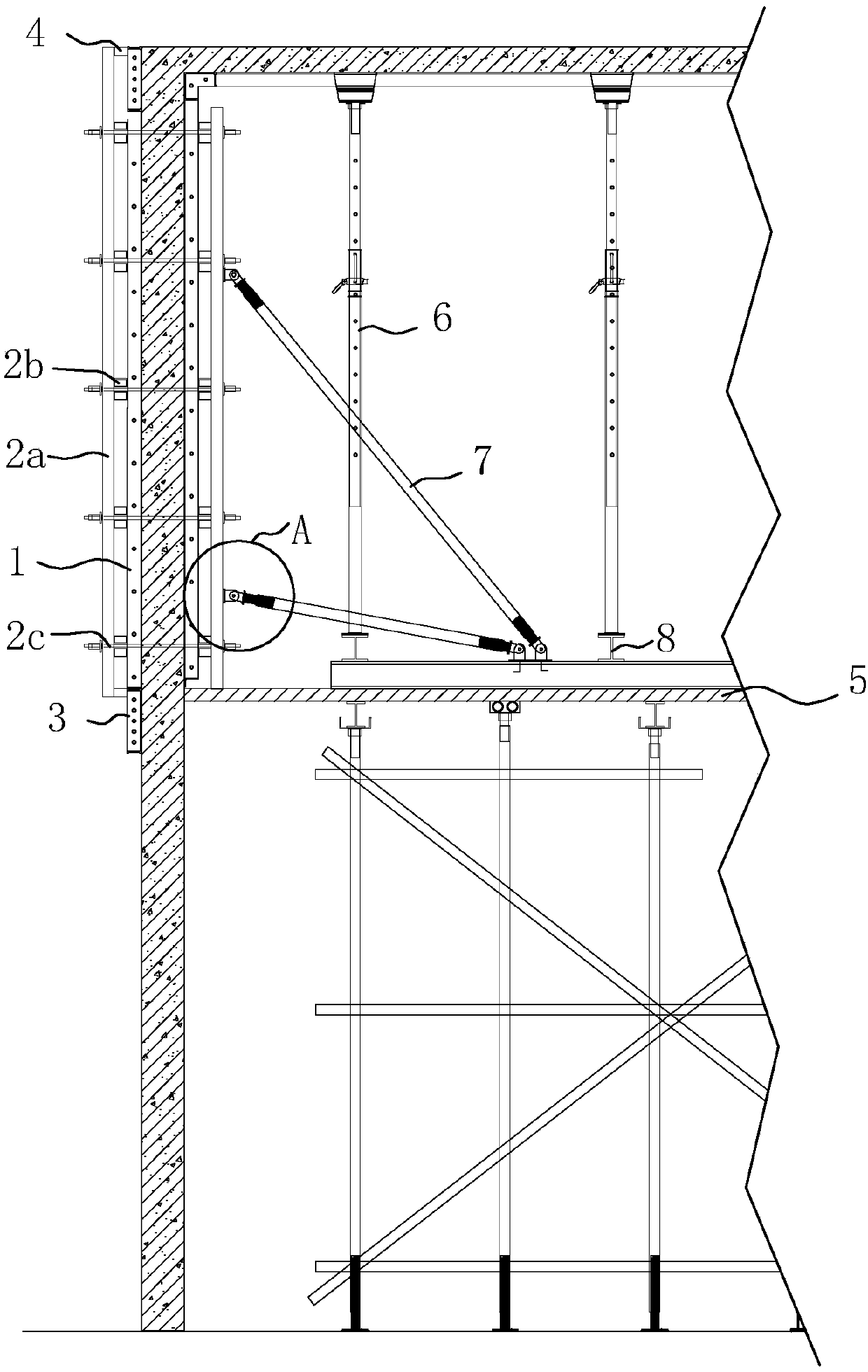

[0049]A tall formwork support system for aluminum alloy formwork, as attached figure 1 And attached figure 2 As shown, it includes the aluminum formwork 1 on the inside and outside of the building wall, the vertical back flute 2a and the horizontal back flute 2b, and the vertical back flute 2a is located on the side of the aluminum formwork 1 away from the wall, and the horizontal back flute 2b is located on the vertical back flute 2a and the aluminum formwork 1 are arranged with equal height differences. And the inner and outer vertical back flute 2 and horizontal back flute 2b are arranged symmetrically with respect to the wall surface. Moreover, the bilaterally symmetrical vertical back flutes 2a and horizontal back flutes 2b and the aluminum formwork 1 are connected together by tension screws 21 . In this way, on the one hand, the vertical back flute 2a and the horizontal back flute 2b can support and stabilize the aluminum formwork 1, and on the other hand, the pull sc...

Embodiment 2

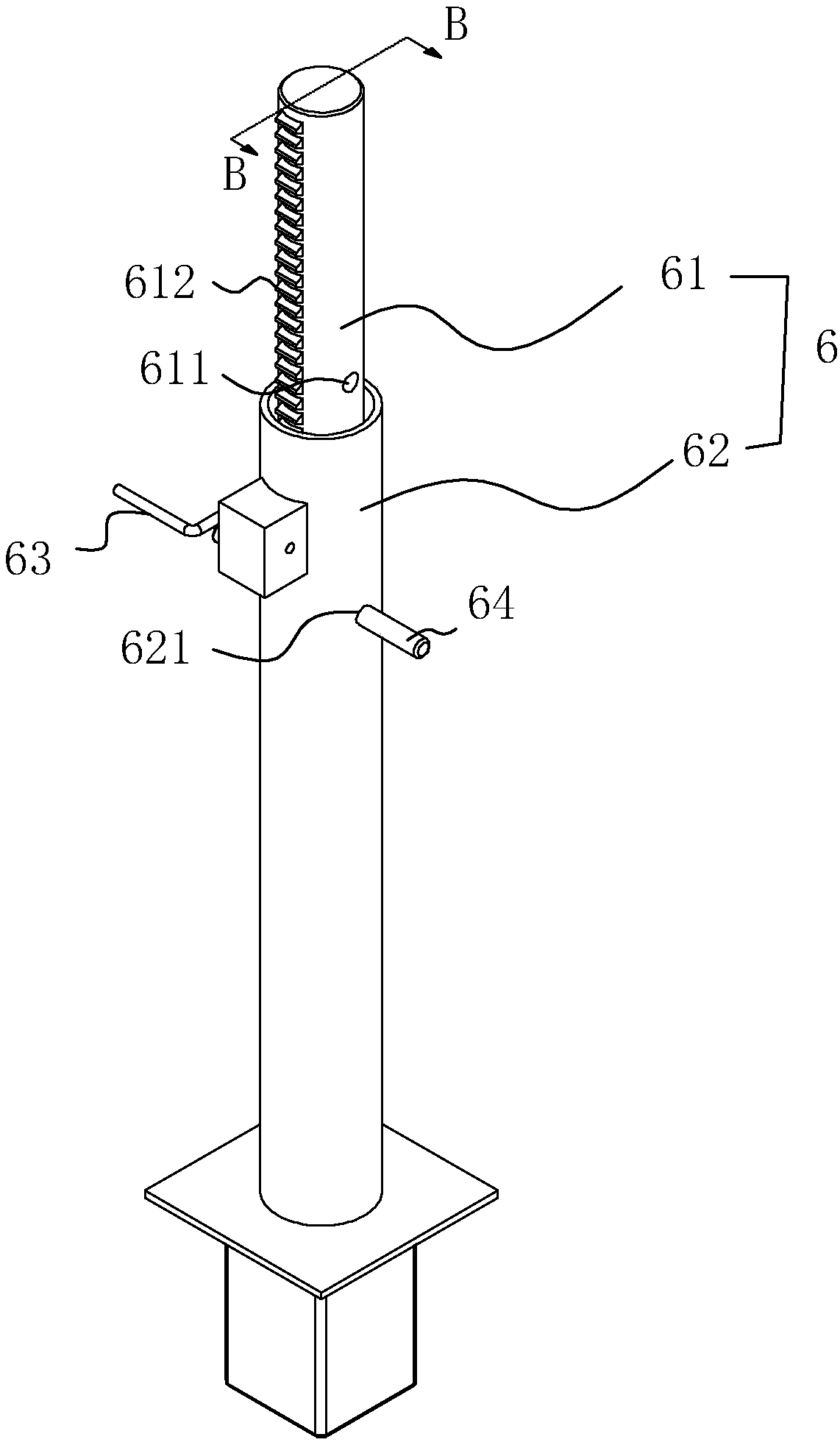

[0053] A tall formwork support system for aluminum alloy formwork, as attached image 3 And attached Figure 4 As shown, on the basis of Embodiment 1, an operating platform 5 is also included. The operating platform 5 is located inside the building, and the operating platform 5 is located at the height of the middle of the building, with a liftable support pipe 6 below it. The lower end of the support pipe 6 stands on the ground, and the upper end supports the operating platform 5 . And, here the support tube 6 includes an inner tube 61 and an outer tube 62, and the outer peripheral surface of the inner tube 61 is provided with two rows of holes 611 symmetrical to the axis of the inner tube 61, while the outer tube 62 is provided with two rows respectively The positioning holes 621 corresponding to the two rows of holes 611, and when the two rows of holes 611 and the two positioning holes 621 are aligned, can just allow a bolt 64 to pass through, thereby ensuring that the inn...

Embodiment 3

[0057] A method for installing an aluminum alloy formwork tall formwork support system, comprising the following construction steps:

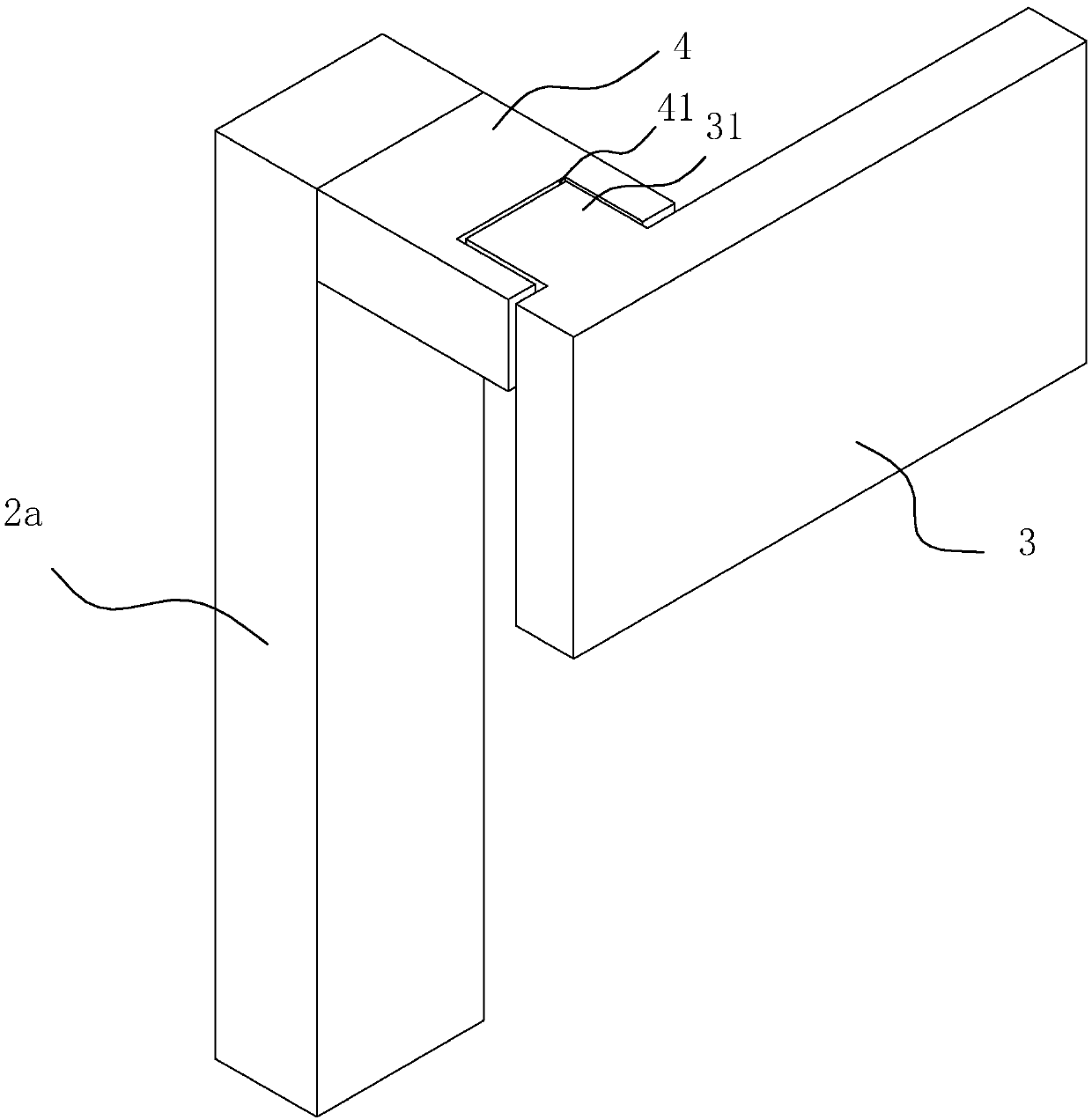

[0058] Step 1, arrange two parallel positioning boards 3 at equal intervals with the width of the wall along the plane profile of the building on the ground;

[0059] Step 2, use the pressing block 4 to cooperate with the dovetail groove and the dovetail block along the vertical direction, so that the vertical back flute 2a and the positioning plate 3 are connected;

[0060] Step 3: Place the aluminum formwork 1 on the top of the positioning plate 3, and then set a number of horizontal corrugations between the vertical back corrugated 2a and the aluminum formwork 1 at a height of 40 cm, and use the pull screw 2c to simultaneously place the two parallel aluminum formworks 1 , two parallel vertical back flutes 2a and two parallel horizontal back flutes 2b are connected together;

[0061] Step 4: Diagonal struts 7 are set between the vertical bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com