Photovoltaic energy station and photovoltaic mounting rack and base manufacturing method thereof

A manufacturing method and mounting technology are applied in the field of photovoltaic energy station and photovoltaic mounting and base manufacturing, which can solve the problems of high labor cost, long construction period, and photovoltaic modules cannot be quickly disassembled and placed, and achieve excellent anti-corrosion performance, Low cost and beneficial effect on power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

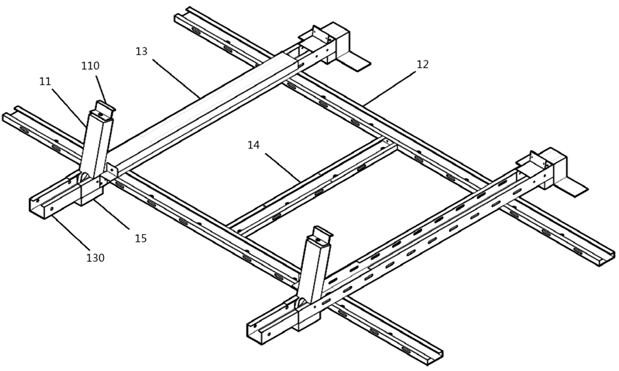

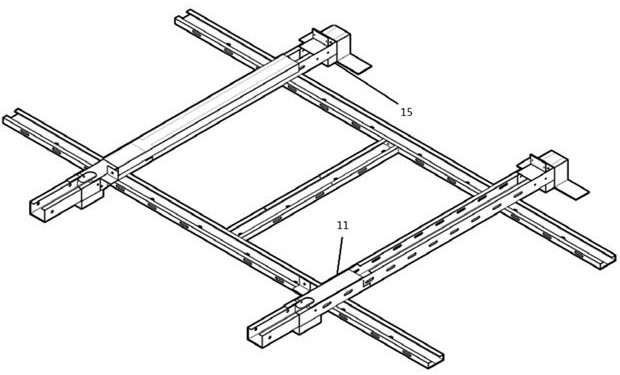

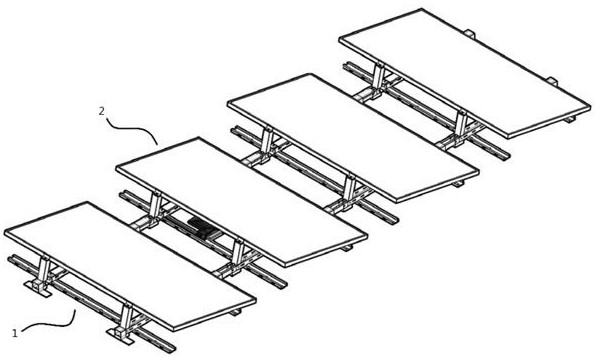

[0037] The present invention will be further described below with reference to the specific embodiments and the drawings, and more details are set forth in the following description to fully understand the present invention, but the present invention obviously be implemented in other ways different from this. Those skilled in the art can make similar promotion according to the actual application without departing from the connotation of the present invention, and thus the scope of the invention should not be limited in this particular embodiment.

[0038] The base production method of the present invention is applied to the metal stent body to provide a connection fixation, including the following production steps:

[0039] The surface treatment of the adhesive form is surface-treated in the plane of the adhesive table, thereby performing drying and polishing the rough surface, and dust free oil treatment;

[0040] The prepared A and B two components are mixed with a mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com