Multi-phase flow fidelity sampling device and method based on drilling

A sampling device and drilling technology, applied in the field of formation multiphase fluid sampling and formation multiphase fluid sampling devices, can solve fidelity sampling (only gas-liquid two-phase, liquid can only be single-phase liquid or mixed state) Liquid, can not consider sample sampling, can not consider the proportion of different phase liquids and other issues, to achieve the effect of wide application range, stable system and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0075] Take China United Coal Changzi County CO 2 Take the coalbed methane displacement site as an example (the downhole liquid has no oil-water mixture, and the gas samples taken have not been collected for related experiments). The steps are:

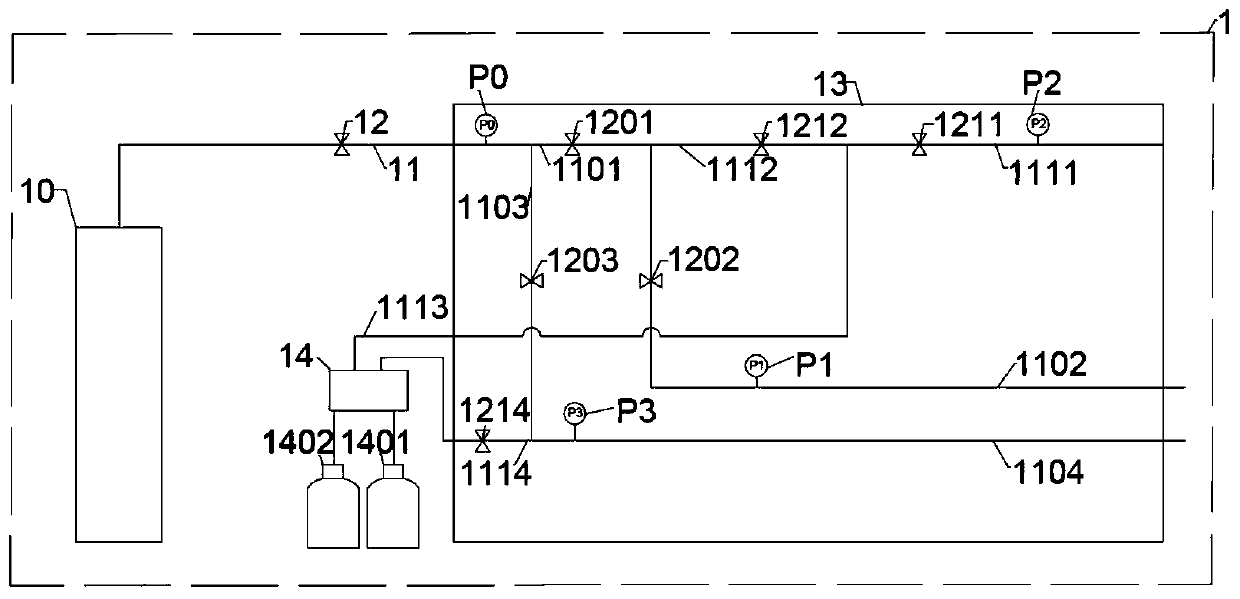

[0076]1. Open the pressure source 10 to release the high-pressure relatively inert gas, adjust the fluid pressure reducing valve 12 to the maximum output pressure (the general pressure is about 12Mpa, related to the drilling depth), open the first liquid drive pipe valve 1201, the second liquid drive pipe valve 1201 The valve 1202 and the first liquid sampling pipe valve 1211 inject high-pressure relatively inert gas into the U-shaped liquid sampling pipe 2; the high-pressure relatively inert gas leaves the pressure source 10 and passes through the first driving pipe 11, the first liquid driving pipe 1101, the second The liquid driving tube 1102 is then injected into the downhole control pipeline 21 and sampling pipeline 22 of the U-...

Embodiment 2

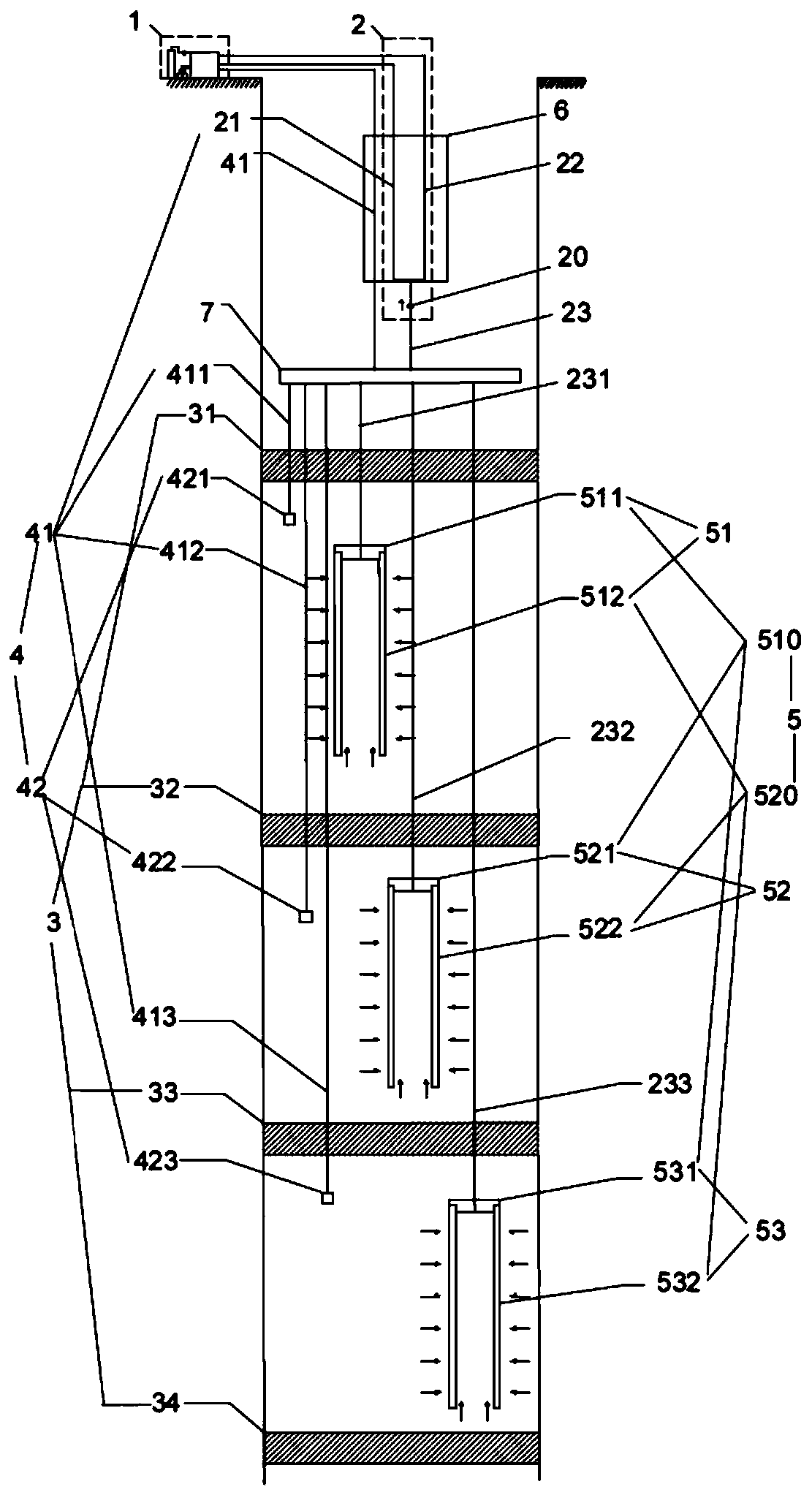

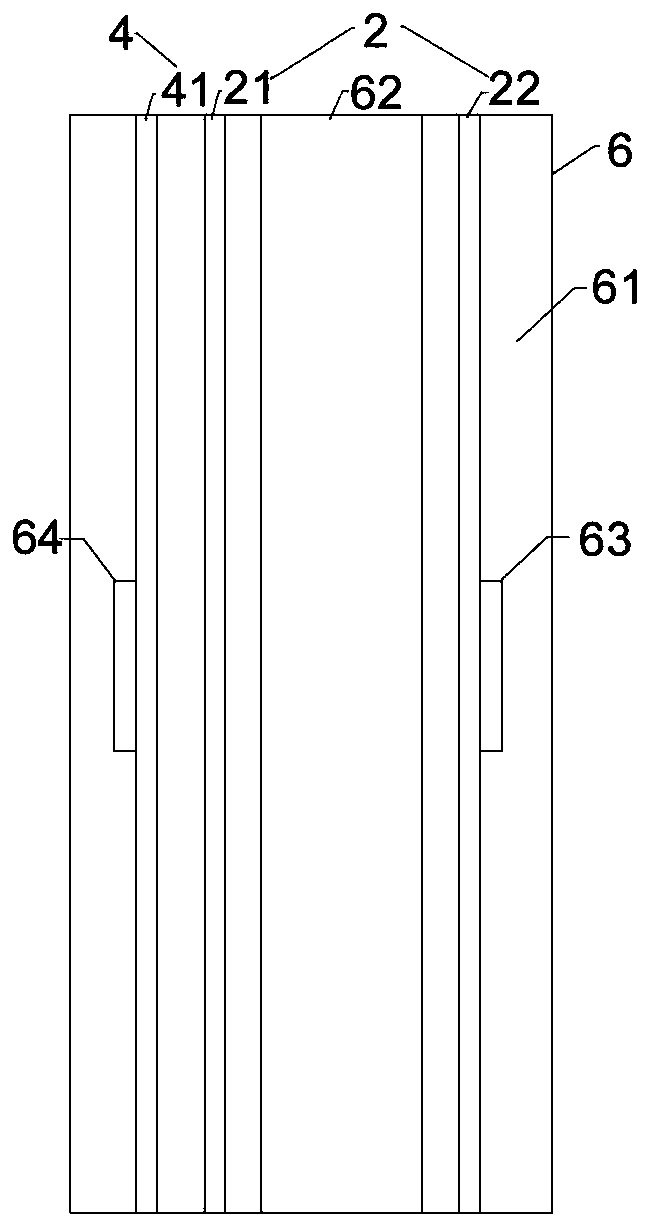

[0087] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 The present invention is further described: a multiphase flow fidelity sampling device for drilling, which includes a surface control system 1, a U-shaped liquid pipe 2, a packer system 3, an I-type gas pipe 4, a porous pipe downhole Liquid sampling system 5, temperature control system 6, automatic multi-way valve 7. The present invention is different from the existing U-shaped tube gas-liquid two-phase sampling device, and adds a ground control system 1 and a porous tube downhole liquid sampling system 5, and is characterized in that: the pressure source 10 and the first drive in the ground control system 1 The pipe 11 and the fluid pressure reducing valve 12 are connected; the control pipeline 21 in the U-shaped liquid taking pipe 2 is respectively connected with the sampling pipeline 22, the ground control system 1, and the liquid sampling pipe 23, and the liquid sampl...

Embodiment 3

[0104] Such as Figure 8 , Figure 9 , Figure 10 In the drilling at a depth of 1000m (underground temperature is about 30°C), the original sampling method and the device and sampling method of the present invention are used to sample, and the stability of the pressure of the underground fluid during the sampling process has been greatly improved. Effective control of fluid external conditions. Its implementation steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com