Psi-type pipe multi-phase fidelity sampling method and device suitable for ultra-low permeability stratum

A sampling device and formation technology, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of slow formation pressure drop, reduced sample representativeness, insufficient natural energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0091] Example 1: Carry out the sampling flow process that carries out on-the-spot implementation with certain place according to the present invention, flow process is carried out strictly according to standard procedure, the pressure source (10) that on-the-spot use is the N of maximum pressure 15MPa 2 Steel cylinder, the driving fluid type is high-pressure inert gas, and the pressure change record is as follows: Figure 8 As shown, the pressure change compared with the original method sampling is as follows Figure 7 As shown, the pressure disturbance of the pressure formation is small.

[0092] A Ψ-type tube multi-phase fidelity sampling method applicable to ultra-low permeability formations, using a set of Ψ-type sampling tubes and a set of I-type sampling tubes in combination for gas-liquid sampling in general low-permeability formations, the steps are:

[0093] (1) Open the pressure source 10, the fluid pressure reducing valve 12, the first gas drive pipe valve 1201, t...

example 2

[0098] Example 2: when using the device sampling of the present invention in the ultra-low permeability formation, the gas sample and the liquid sample sampling all use the Ψ type sampling tube to sample, and the pressure source 10 used on-site is the high-pressure inert gas N of the highest pressure driving fluid that is 15MPa 2 Steel cylinder and purified water pressurized by a pressurizer (output pressure is 15MPa), the pressure change record is as follows Figure 9 As shown, the pressure change compared with the original method sampling is as follows Figure 7 As shown, the pressure has almost no disturbance to the formation pressure.

[0099] A Ψ-shaped tube multi-phase fidelity sampling method suitable for ultra-low permeability formations. In view of the rare situation of ultra-low permeability formation gas samples, two sets of Ψ-shaped sampling tubes are used for gas-liquid sampling. The steps are:

[0100] (1) Open the pressure source 10, the fluid pressure reducing...

example 3

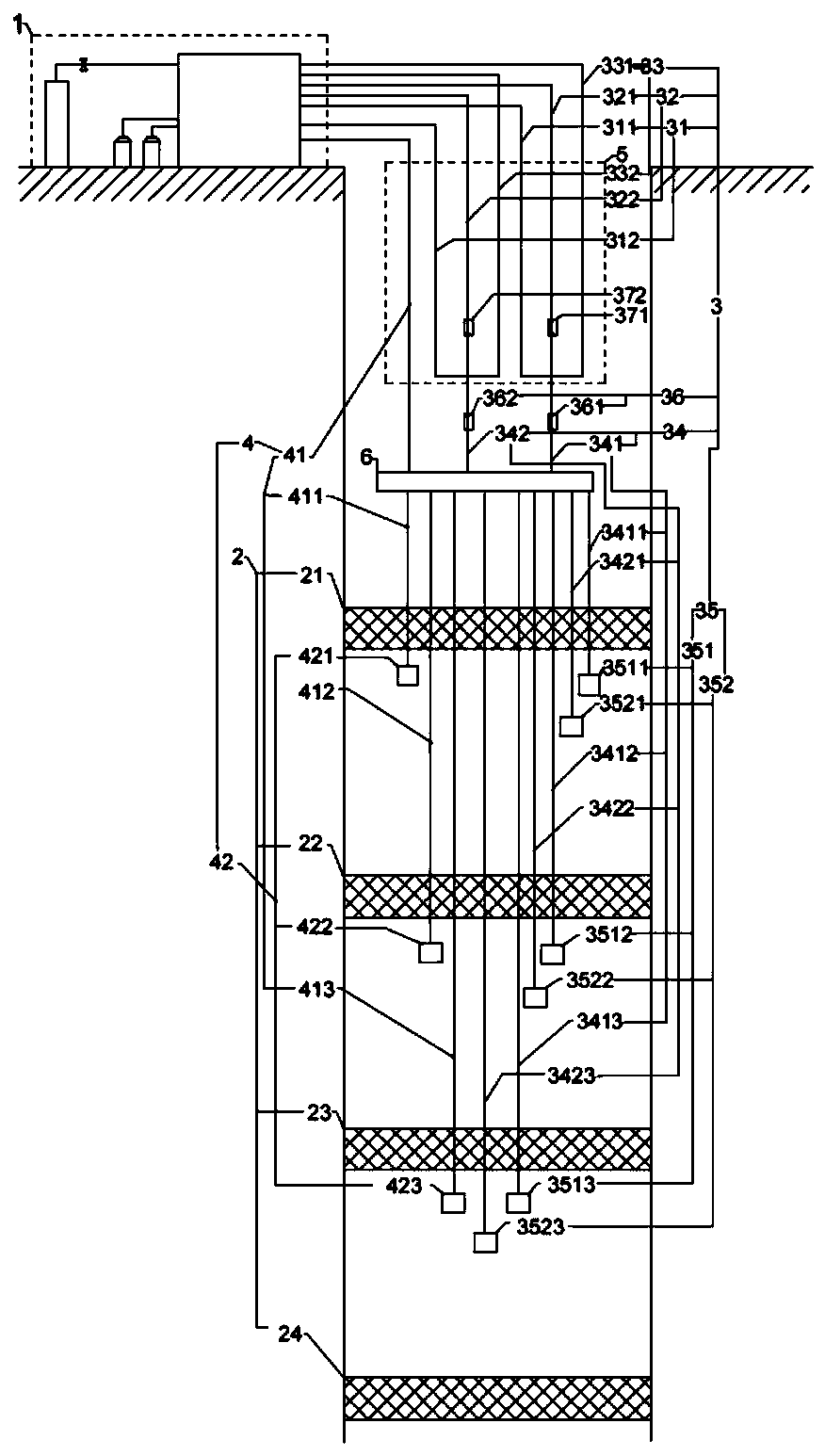

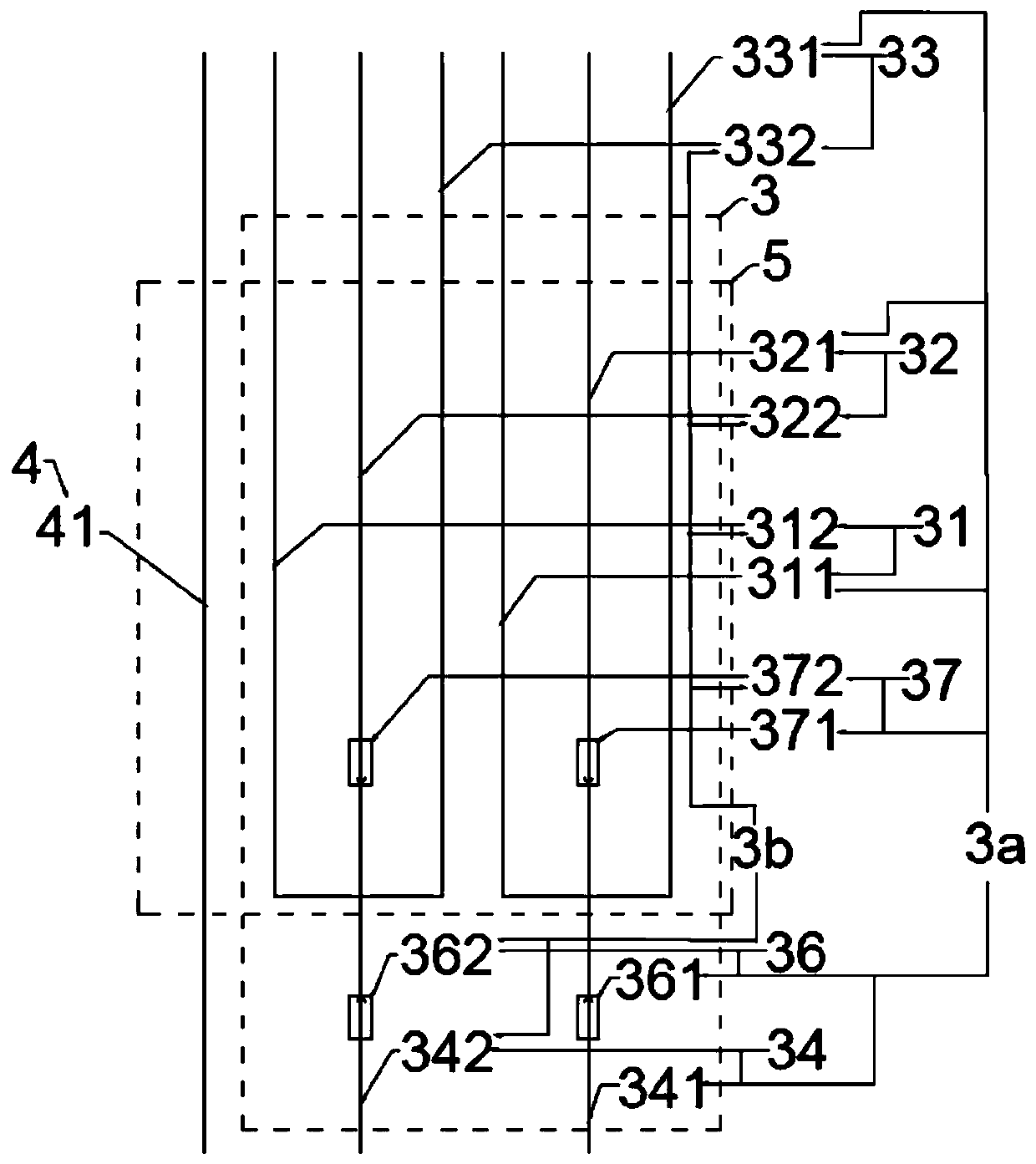

[0106] Example 3: Combine below Figure 1-Figure 6 The inventive device is described in detail:

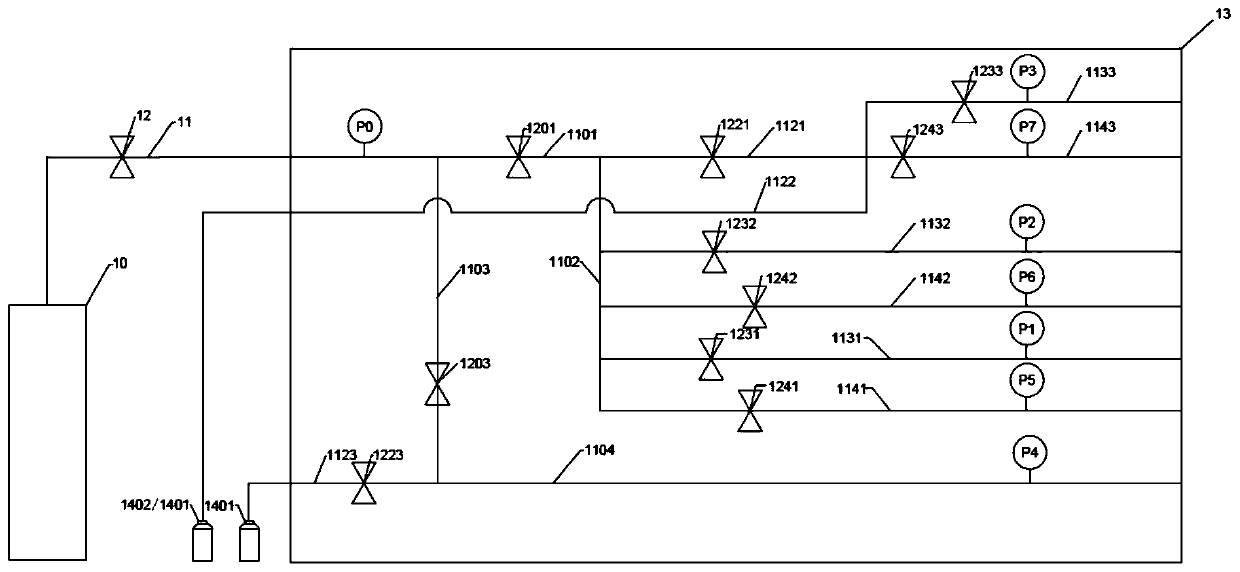

[0107] A Ψ-type tube multi-phase fidelity sampling device suitable for ultra-low permeability formations, which includes a ground control system 1, a packer system 2, a Ψ-type sampling tube 3, an I-type sampling tube 4, a temperature control system 5, an automatic multiple Through the valve 6, the present invention is different from the previous U-shaped tube gas-liquid two-phase sampling device. The ground control system 1 is added on the ground and the U-shaped sampling tube of the original device is replaced with Ψ-shaped sampling tube 3 and Ψ-shaped sampling tube 3 Functionally, it can completely replace the U-shaped sampling pipe; in the ground control system 1, the pressure source 10 is connected to the first driving pipe 11 and the fluid pressure reducing valve 12 and then connected to the control panel 13, and the control panel 13 is connected to the gas sampling container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com