Method for determining purity and impurity content of 1,3,3,3-tetrafluoropropene product by gas chromatography

A technology of gas chromatography and tetrafluoropropene, which is applied in the field of analysis and determination of fluorine-containing olefin products and their impurities, and can solve problems such as difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

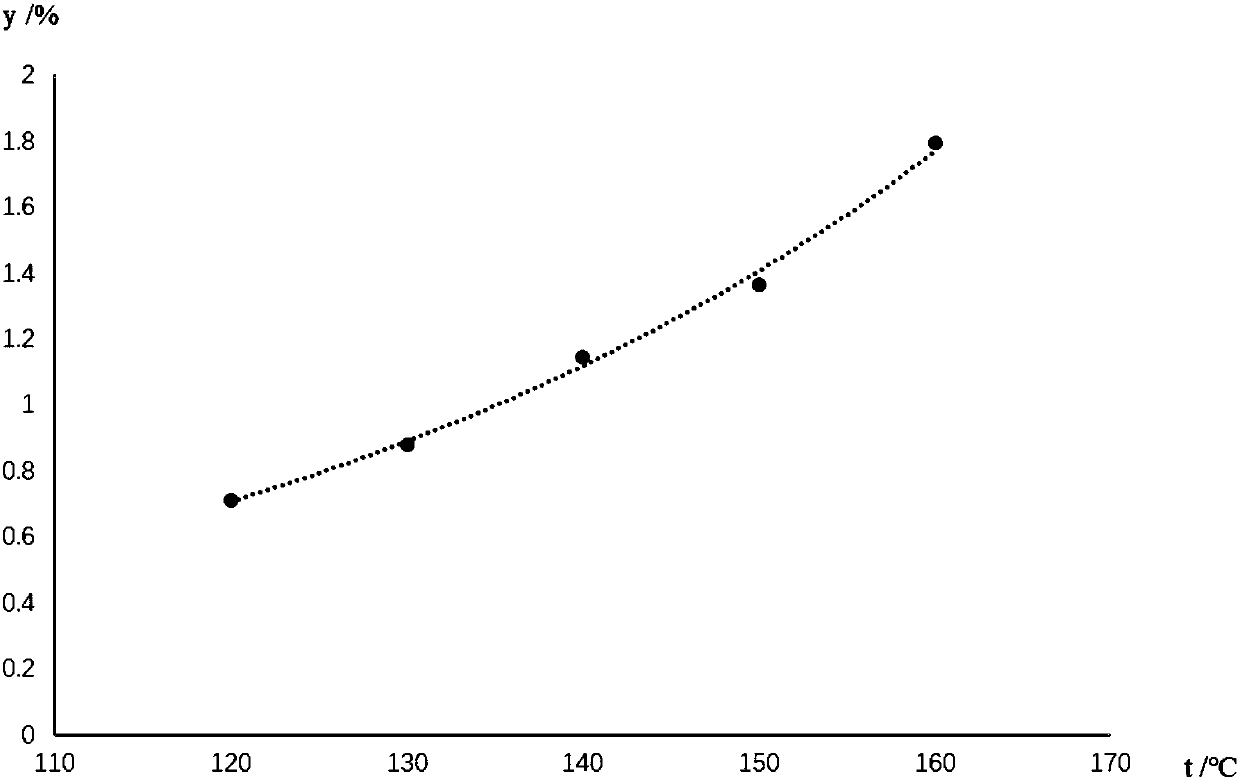

Method used

Image

Examples

Embodiment 1

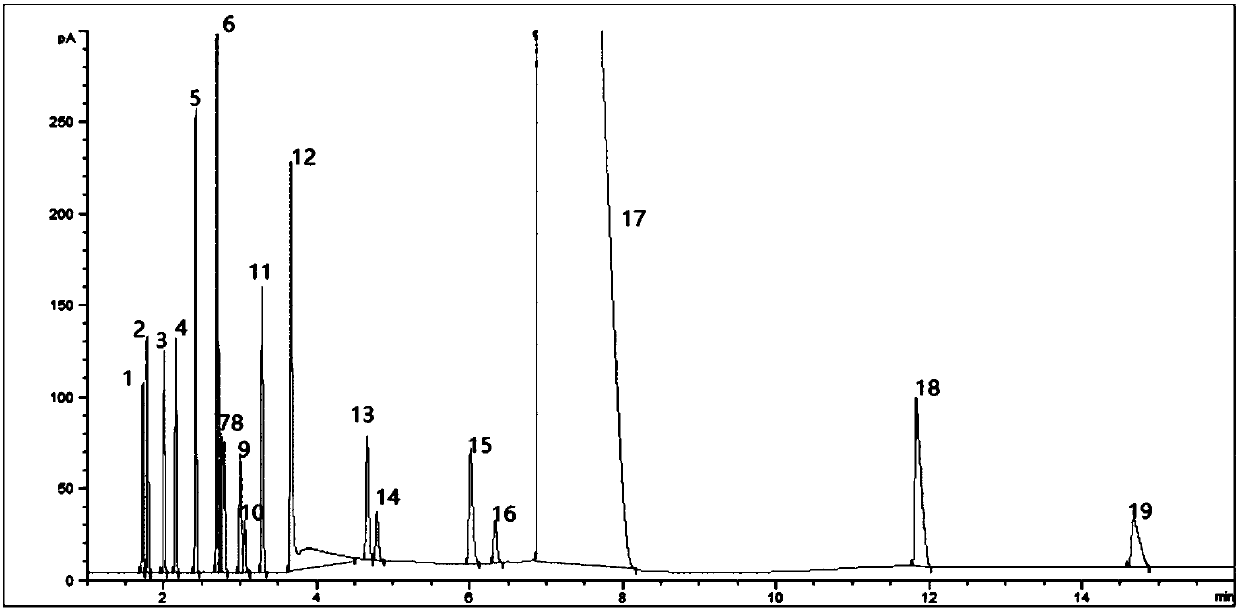

[0041] A 7890A gas chromatograph and FID detector from Agilent were used.

[0042]Test sample preparation: Inject 2.05g of HFO-1234ze(Z) sample into a 1L vacuum-treated air bag, inject 0.4ml methane, 5ml R116, 0.2ml R115, 0.2ml R1216, 0.2ml R143a, 0.2ml with a sealed syringe R1234yf, 0.2ml R114, 0.2ml R114a, 0.2ml 3,3,3-trifluoropropyne, 1.0ml R1112, 0.2ml R245cb, 0.2mlR1234ze(E), 0.5ml R1233xf, 0.2ml R124, 0.5ml R1233zd(Z ), 0.2ml R133a, 0.2ml R245fa, 0.2ml R245eb, the operating environment of the above gases and the background gas should be consistent.

[0043] Select the chromatographic conditions as follows:

[0044]

[0045] The prepared sample to be tested is carried by the carrier gas through the selected chromatographic column, and the components are separated by different partition coefficients between the mobile phase (carrier gas) and the stationary phase in the chromatographic column. Enter the detector; different substances have different characteristics, and...

Embodiment 2

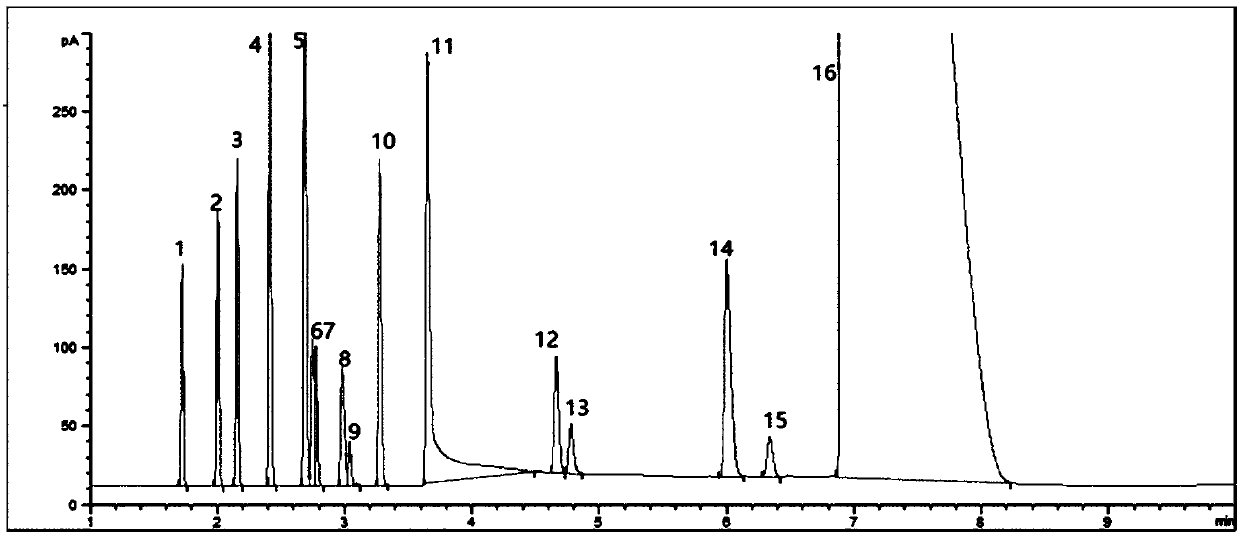

[0050] A 7890A gas chromatograph and FID detector from Agilent were used.

[0051] Test sample preparation: Inject HFO-1234ze(Z) into a 1L vacuum-treated air bag as background gas, inject methane and appropriate amount of impurities into a sealed syringe including: R115, R1216, R143a, R1234yf, R114, R114a, 3, 3,3-Trifluoropropyne, R1112, R245cb, R1234ze(E), R1233xf, R124, R1233zd(Z), R133a. The operating environment of the above-mentioned gases and the background gas shall be consistent. Select the same chromatographic conditions as in Example 1 to analyze, and the chromatogram is detailed in the attached description image 3 .

[0052] The content of each impurity is calculated as follows. First use (2) (3) correction formula to correct the R1234ze(E) and R1234ze(Z) peak areas, and then use (1) area normalization method to calculate, the results are as follows:

[0053]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com