Debris flow control parameter design optimization method considering freeze-thaw cycle effect

A freeze-thaw cycle and debris flow technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve problems such as not considering freeze-thaw cycles and high parameter values, achieving significant applicability advantages and strengthening pertinence , the effect of improving the accuracy of the value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

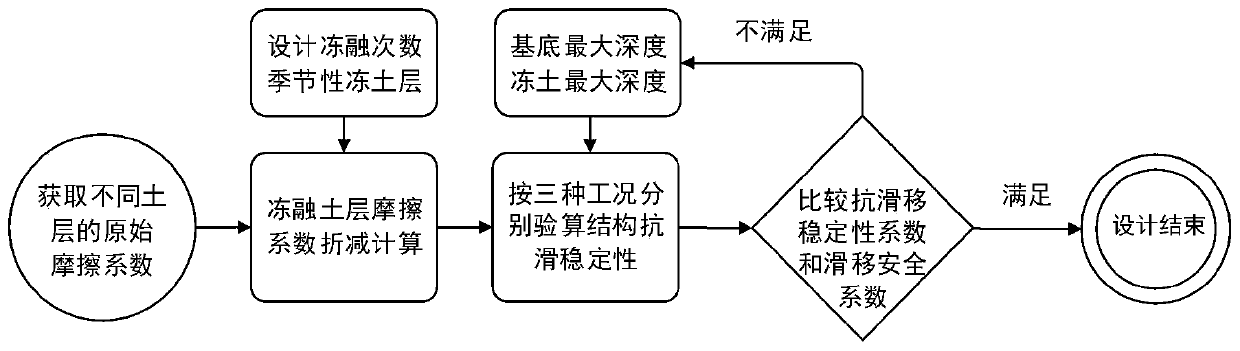

Method used

Image

Examples

Embodiment

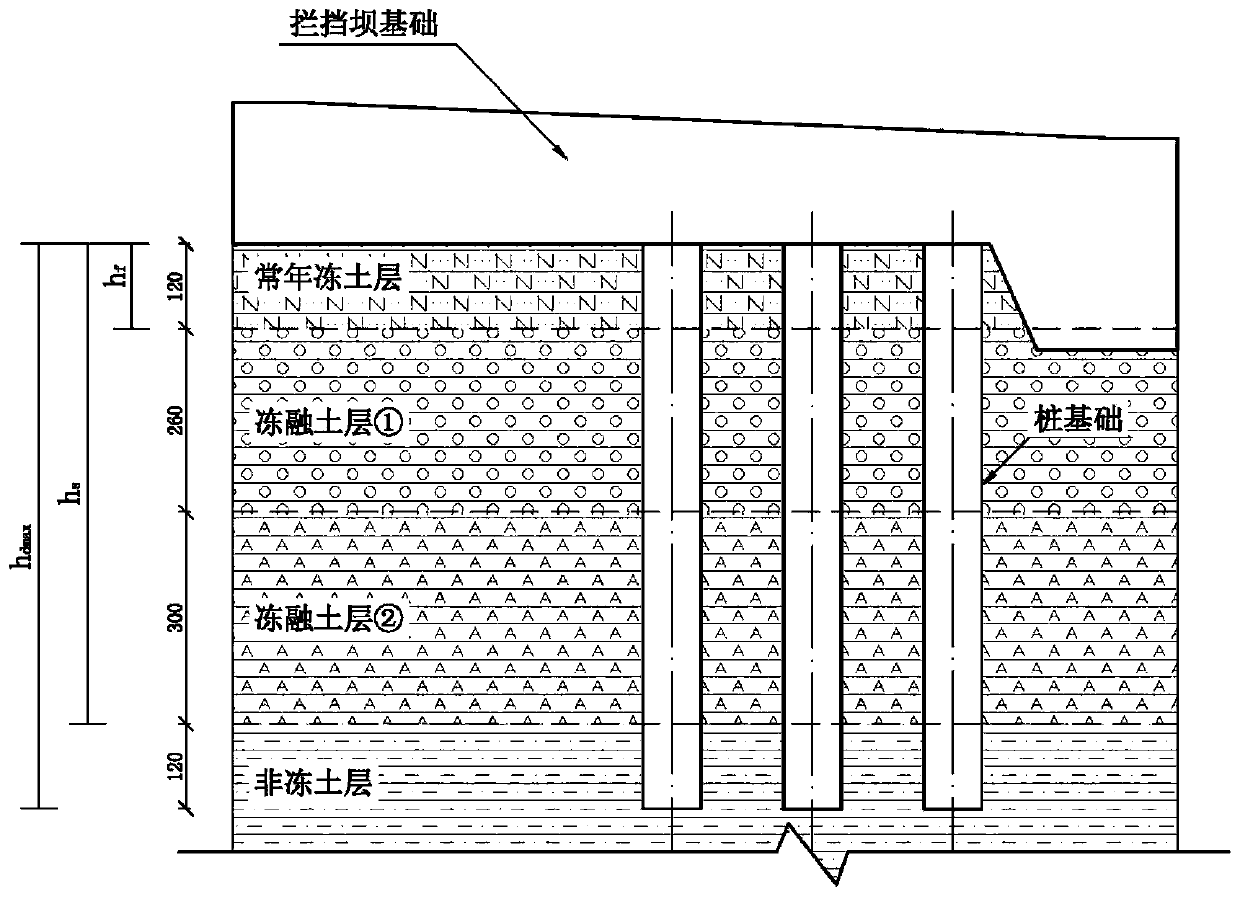

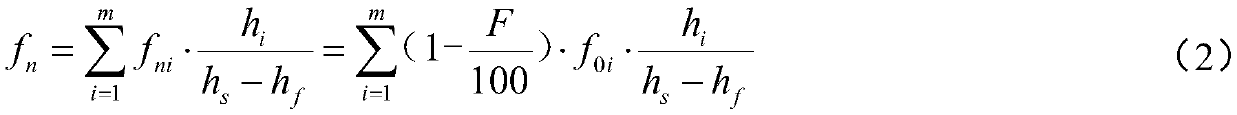

[0059] Such as figure 2 As shown, a debris flow ditch is located in Jiangda County, Gongbu, Tibet. According to the survey data, the permafrost depth of the area where the debris flow ditch is located is h f = 1.2m, depth of seasonal frozen soil h s = 6.8m, a sand control dam is planned to be laid, and the foundation soil layer at the dam foundation is exposed in total 4 layers, and their friction coefficients are: f of the permafrost layer f =0.40; f of seasonal frozen soil layer ① 1 =0.45 (thickness h 1 =2.6m), f of seasonal frozen soil layer ② 2 =0.50 (thickness h 2 =3.0m); f of the underlying non-frozen soil layer 0 = 0.60.

[0060] According to the fortification level and specific prevention and control objectives of the prevention and control project, the design service life of the project is determined to be 20 years, the dam foundation structure adopts pile foundation, and the maximum design depth of the base is h dmax = 8.0 m. According to the movement parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com