Wear optimized pad design

A technology of brake pads and friction materials, applied in mechanical equipment, brake components, brake parts, etc., can solve problems such as inconsistency of brake pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

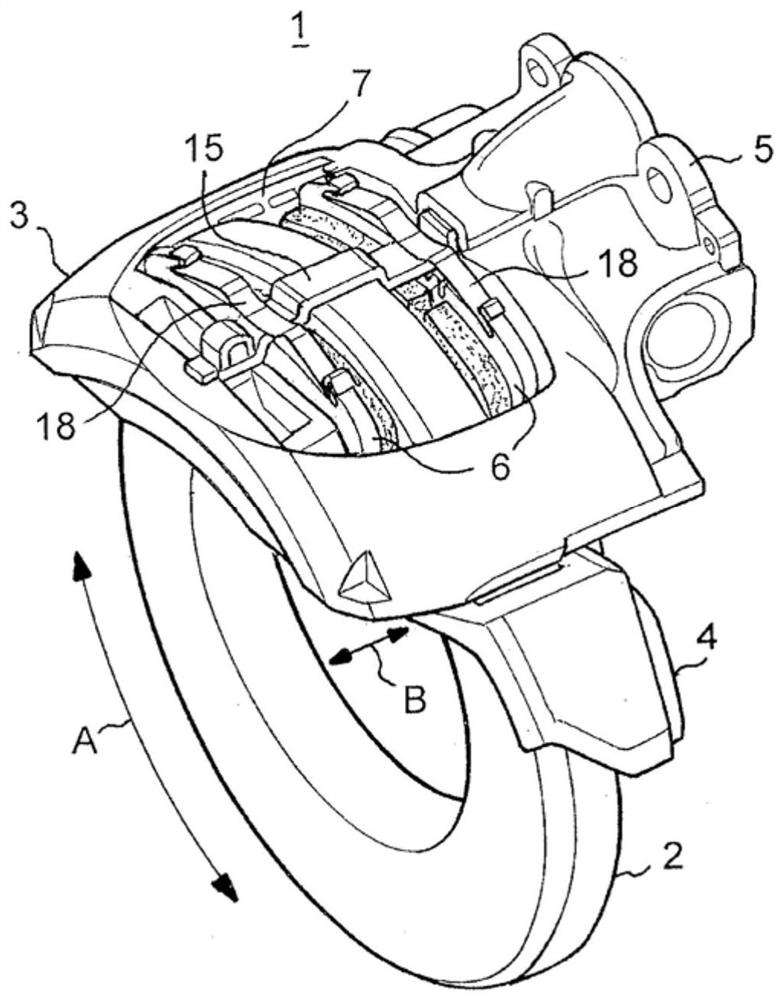

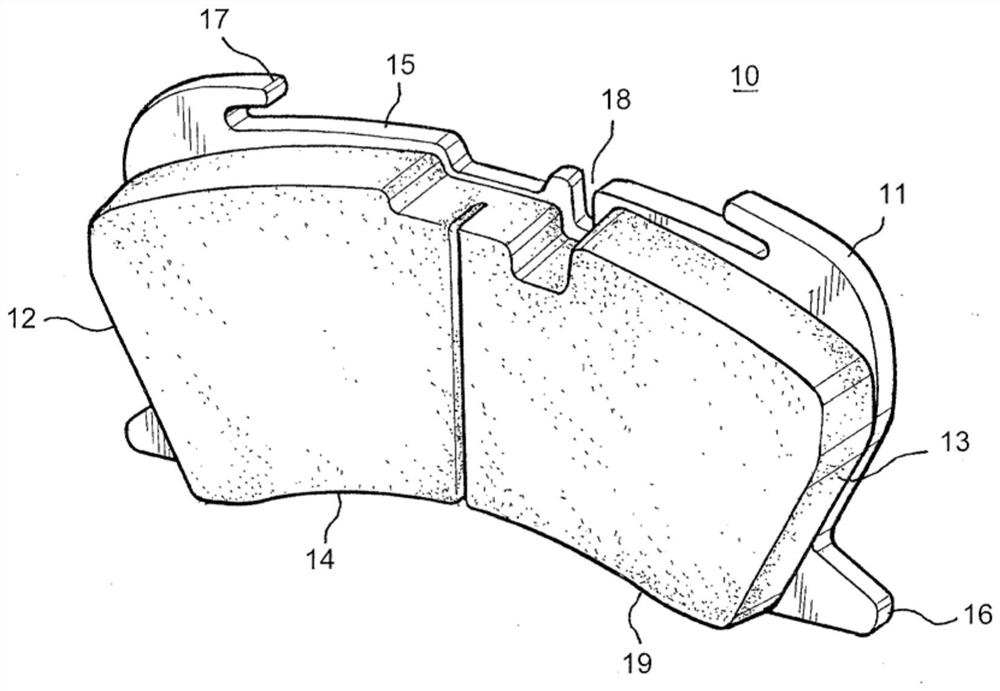

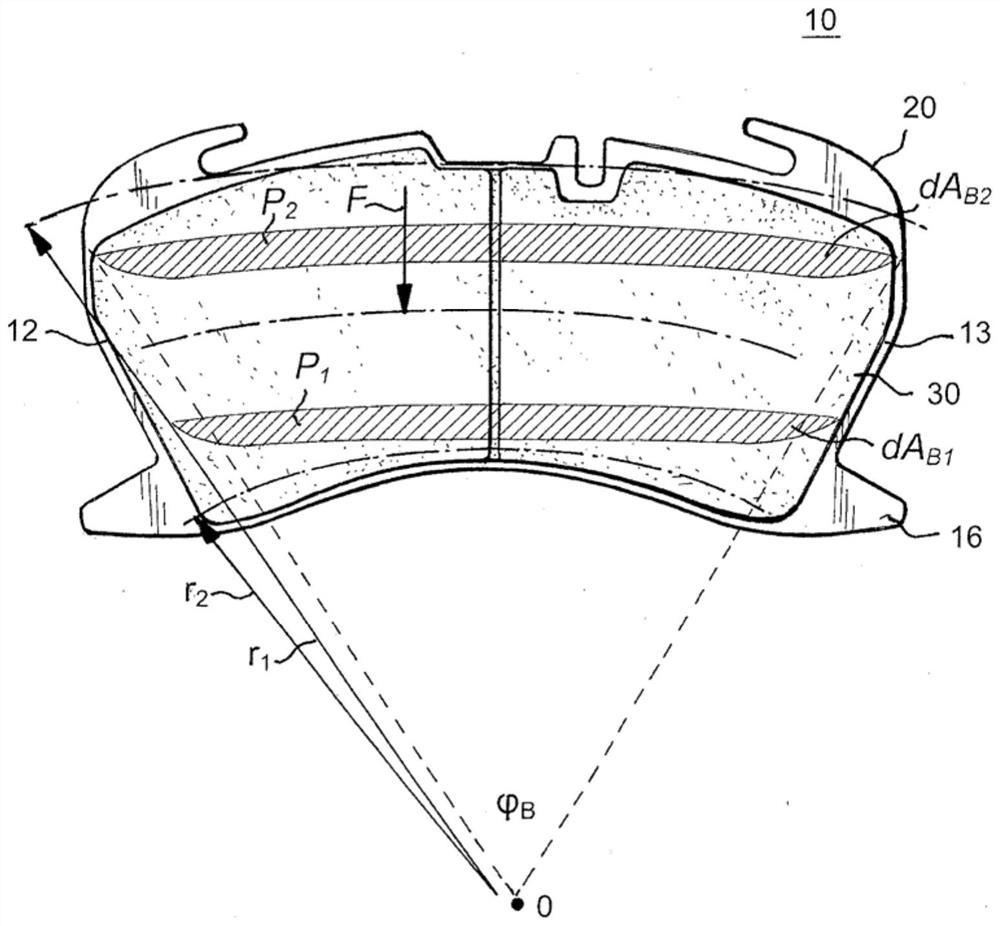

[0022] figure 2 is an oblique view of an embodiment of the present invention, wherein the brake pad 10 includes a back plate 11 to which the friction material 19 of the brake pad is affixed. Such as image 3 As shown, the lateral sides 12 , 13 of the brake pad 10 are generally aligned along a radius extending from the axis of rotation of the brake disc 2 (not shown). The radially inner side 14 and the radially outer side 15 of the brake pad 10 are slightly curved, substantially following the curvature of the brake disc.

[0023] The brake pad backing plate in this embodiment includes lateral protrusions 16 formed to engage corresponding brake pad retention features in the carrier seat 4 in the manner disclosed in co-pending application Serial No. 14 / 640,152 so that even in the absence of Without any additional brake pad retention means, once engaged in the receiving feature of the carrier seat, the brake pad is securely retained within the disc brake. The backing plate 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com