Granule spray-seeding construction method

A construction method and agglomeration technology, applied in the fields of botanical equipment and methods, excavation, infrastructure engineering, etc., can solve the problems of poor slope protection effect, complicated construction method, unstable anchoring, etc., to improve the protection and greening effect. , Improve the fixed effect, the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

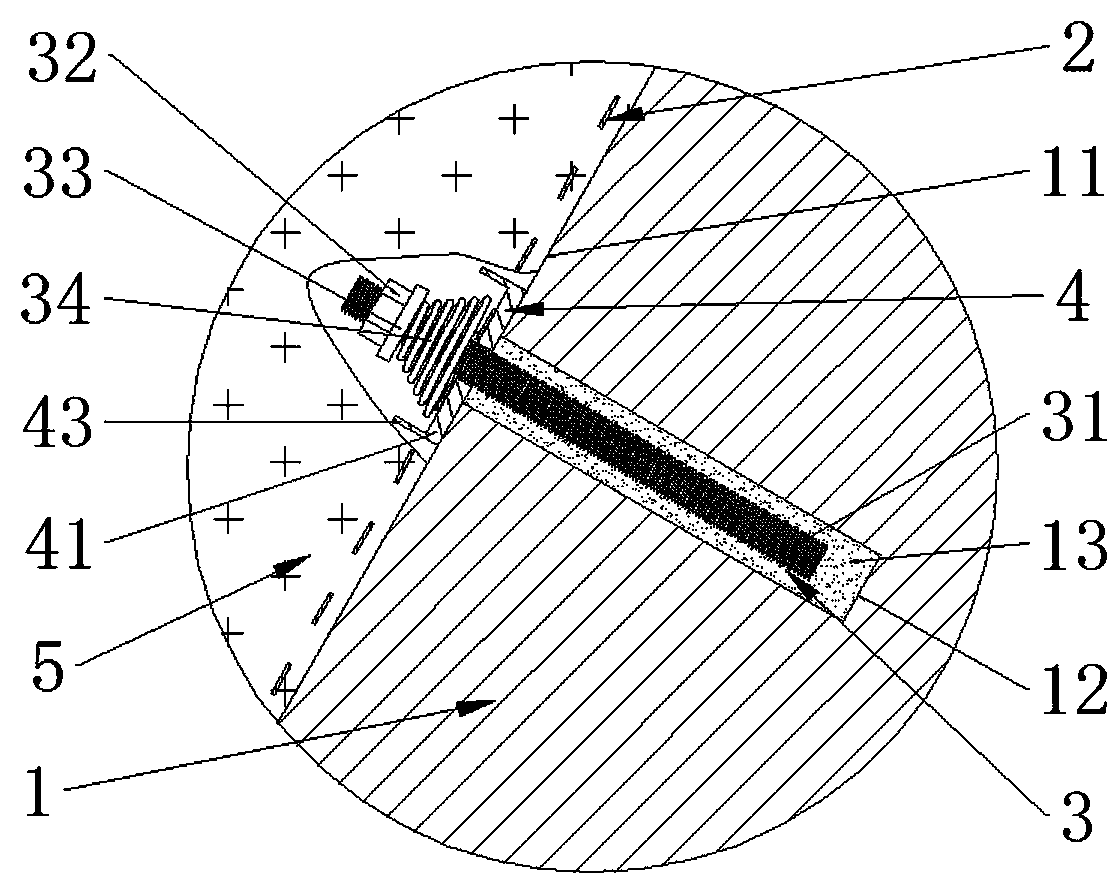

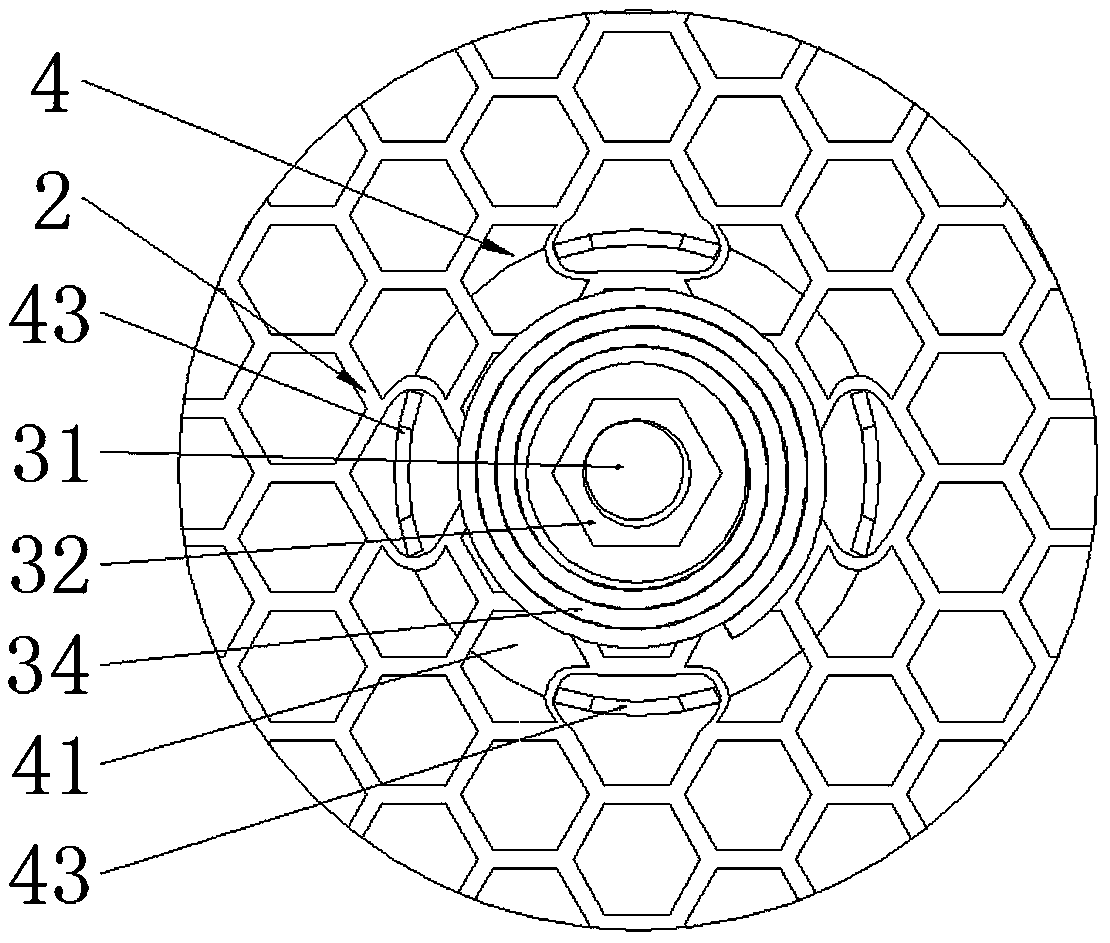

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

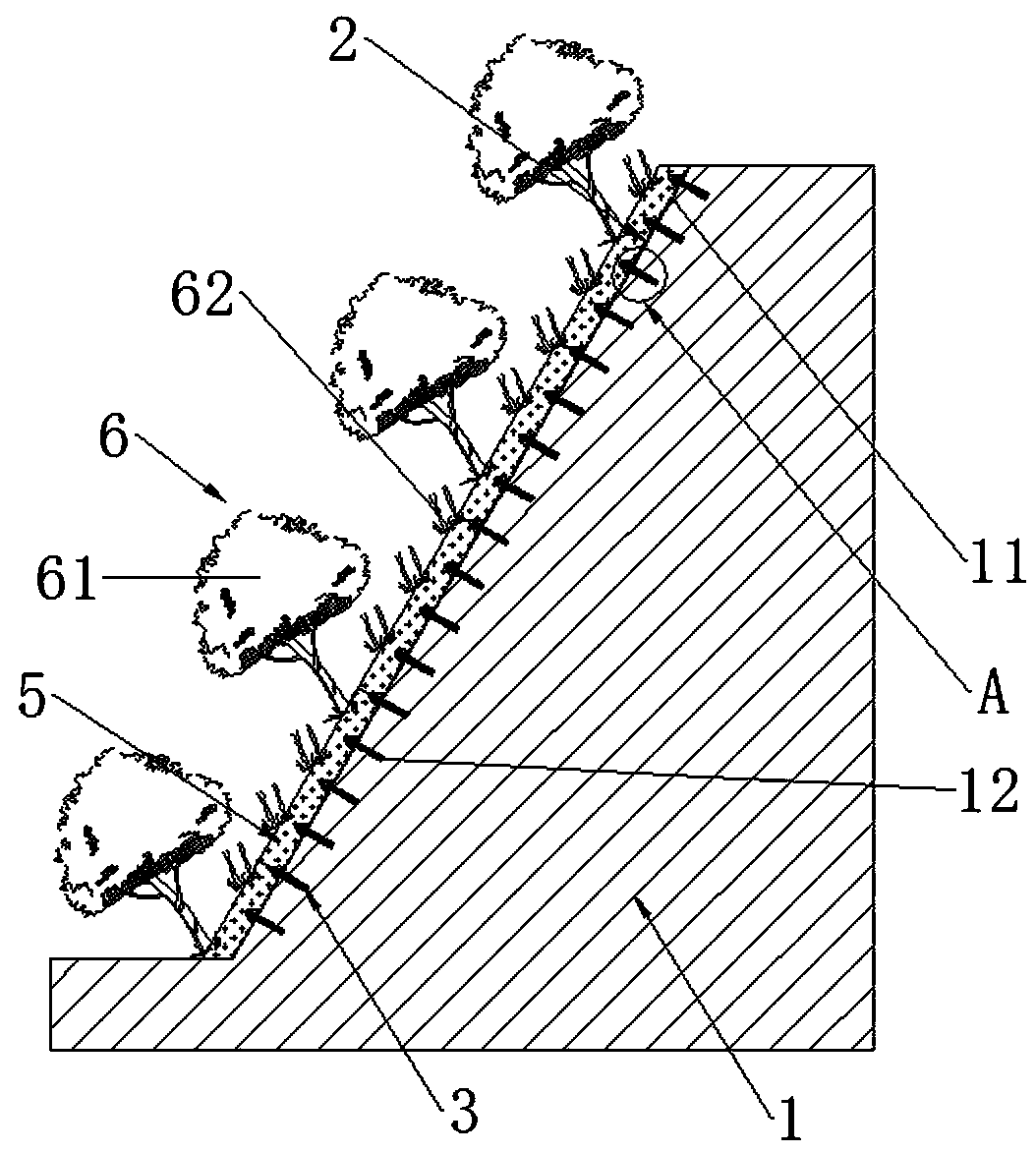

[0035] see Figure 1-5 , a construction method of aggregate spraying, comprising the following steps:

[0036] S1, cleaning the slope surface 11: cleaning and trimming the slope surface 11 of the slope body 1;

[0037] Clean up sundries on the slope 11, remove pumice and loose rocks, and trim the slope body 1 to make the slope 11 smooth so that the barbed wire 2 can be laid. At the same time, check whether there are ditches on the top of the slope to prevent direct erosion of the spraying surface.

[0038] S2, laying barbed wire 2: laying barbed wire 2 from top to bottom on the trimmed slope 11;

[0039] When laying the barbed wire 2, it should be laid from top to bottom along the slope body 1, and the whole barbed wire 2 is launched on the slope 11, and the upper end of the net body is fixed, and then it can continue to be fixed downwards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com