Online electric toothbrush finished product assembly testing device

An electric toothbrush and testing equipment technology, applied in sorting and other directions, can solve problems such as damage to the bottom cover, low efficiency, operator fatigue, etc., and achieve the effects of eliminating leakage testing, reducing labor costs, and reducing fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

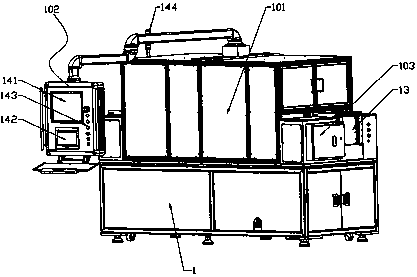

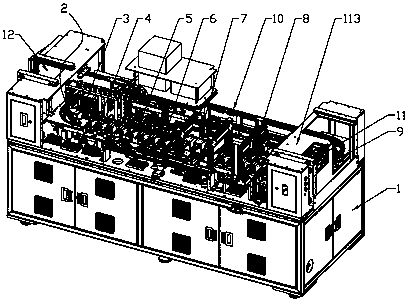

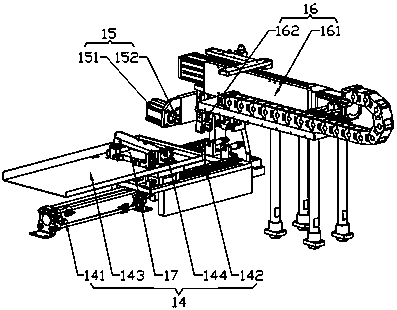

[0029] Such as Figure 1 to Figure 5 As shown, in this embodiment, the present invention includes a test frame 1, and the test frame 1 is provided with a circular transmission guide rail 2 and an operation controller electrically connected with the circular transmission guide rail 2, and the circular transmission The guide rail 2 is sequentially provided with a feeding station 3, a buffer station 4, a front-end leak test station 5, a rear-end leak test station 6, a Bluetooth test station 7, and a near Field and proximity sensor test station 8, discharge station 9, reflow station 10, the top between the near field and proximity sensor test station 8 and the discharge station 9 is provided with the operation control A defective product recovery device 11 electrically connected to the device, and a material loading and capping device 12 electrically connected to the operation controller is provided at the outer end of the feeding station 3 .

[0030] In this embodiment, the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com