Inclined tooth subdivision linear-movement fine adjustment mechanism

A fine-tuning mechanism and technology of helical teeth, applied in the field of machining, can solve the problems of inability to perform fine-tuning and low grinding precision of grinding heads, and achieve the effects of simple structure, simple operation and high adjustment precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

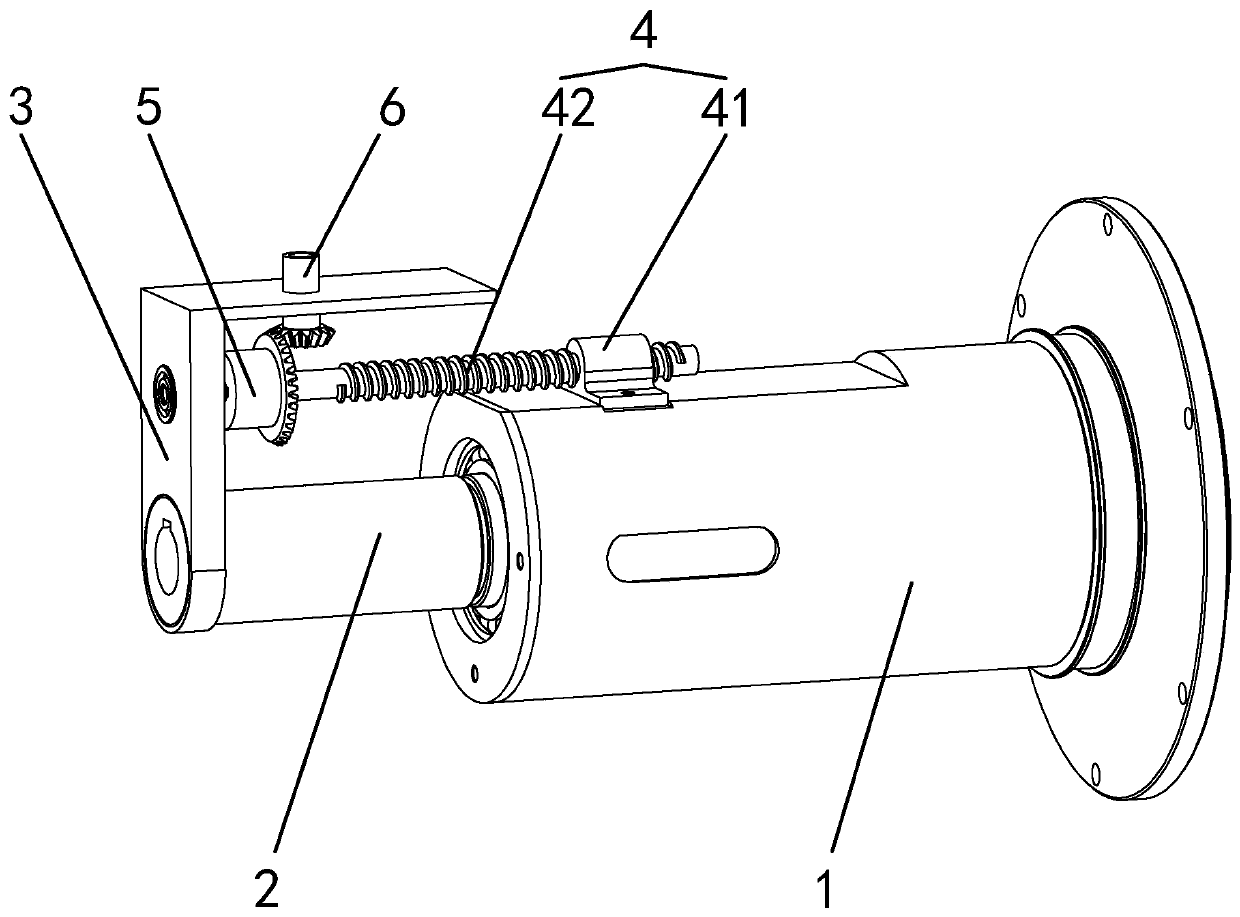

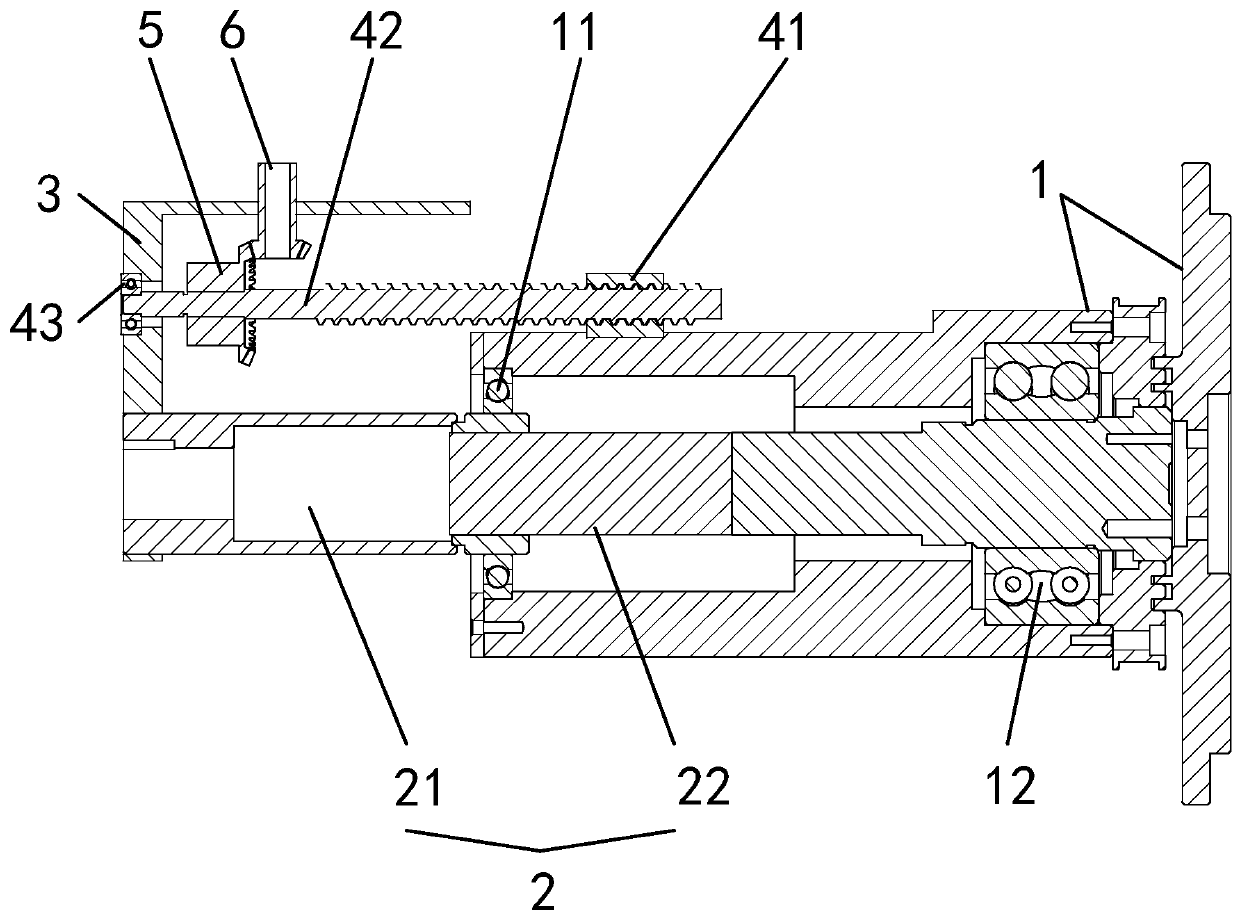

[0014] refer to figure 1 , a helical subdivision direct-motion fine-tuning mechanism, including a work seat 1, on which work accessories are installed, such as a grinding head, a saw blade, a guide mechanism 2 is housed in the work seat 1, and the guide mechanism 2 is connected by a fixed bracket 3 There is a screw assembly 4 installed on the working seat 1, and the screw assembly 4 is covered with a steering bevel gear 5, which is vertically meshed with the steering bevel gear 5. There is an indexing bevel gear 6, and the indexing bevel gear 6 is installed on the fixed bracket 3 , in actual use, a hand wheel with a scale is installed on the indexing bevel gear 6, and the indexing bevel gear 6 is rotated by the hand wheel, so that the steering bevel gear 5 is driven, and then the screw assembly 4 is rotated to make the indexing The rotary motion of the bevel gear 6 is converted into the linear motion of the work seat 1, and the work seat 1 slips on the guide mechanism 2. Becau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com