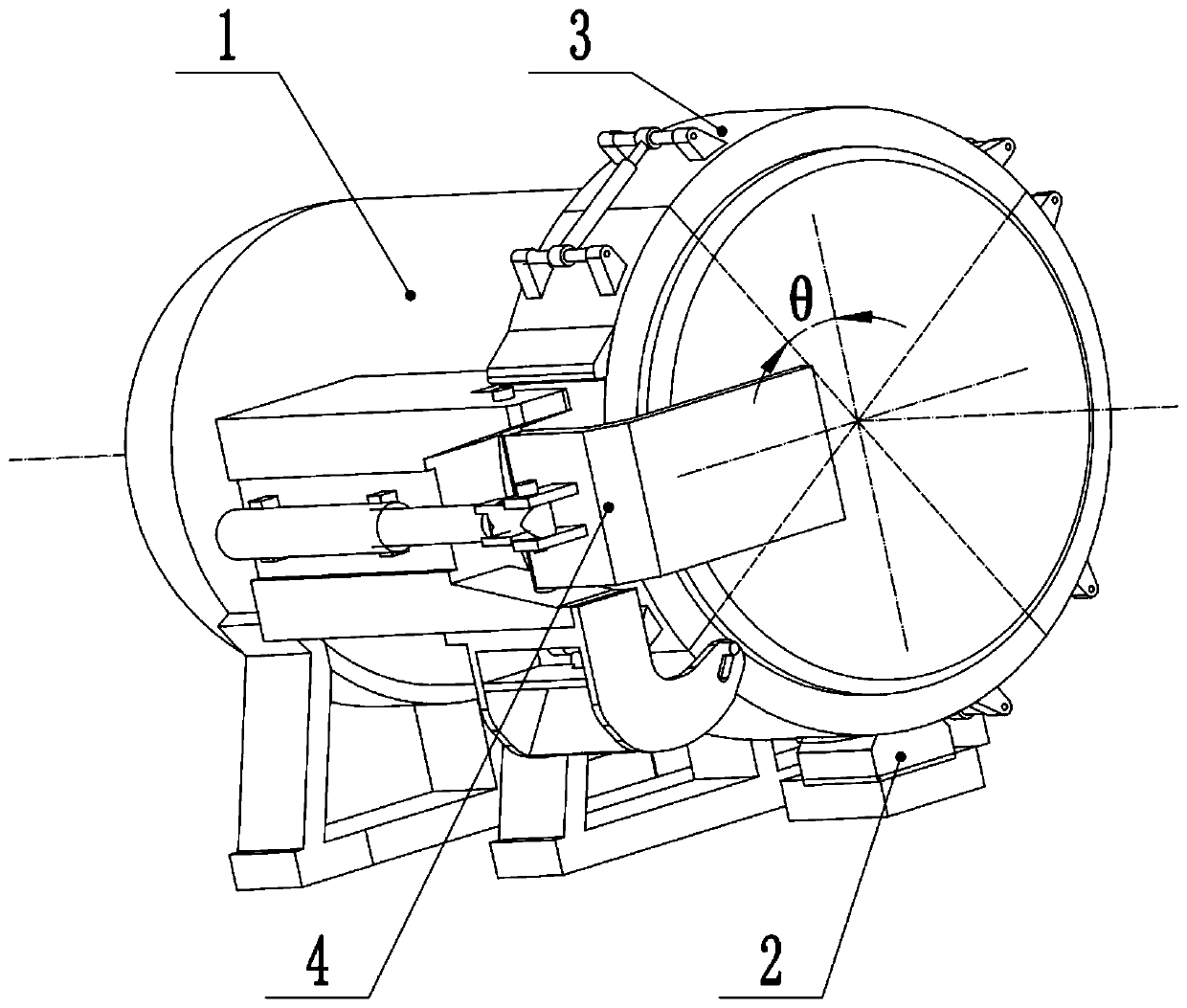

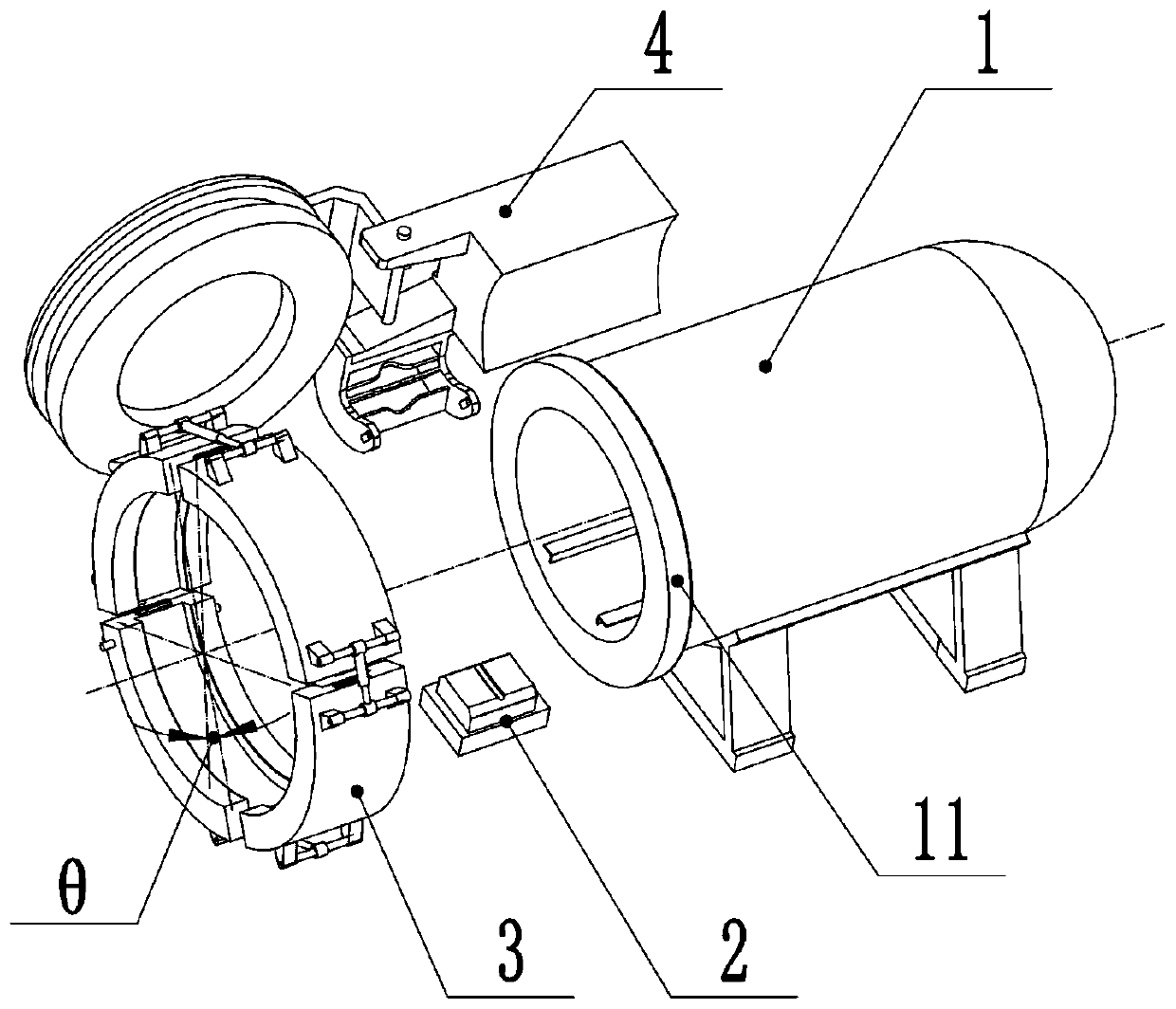

Four-block combination two-way opening and closing clamp horizontal type supercritical fluid foaming quick-opening device

A supercritical fluid and clamp technology, which is applied in the field of four combined two-way open and close clamp horizontal supercritical fluid foaming quick-opening devices, can solve the problem of high labor intensity in opening and closing operations of tanks, and increased space for equipment installation and operation. Large size, low work efficiency and other problems, to achieve the effect of saving installation space, reducing the space occupied by equipment, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 kettle body sealing process

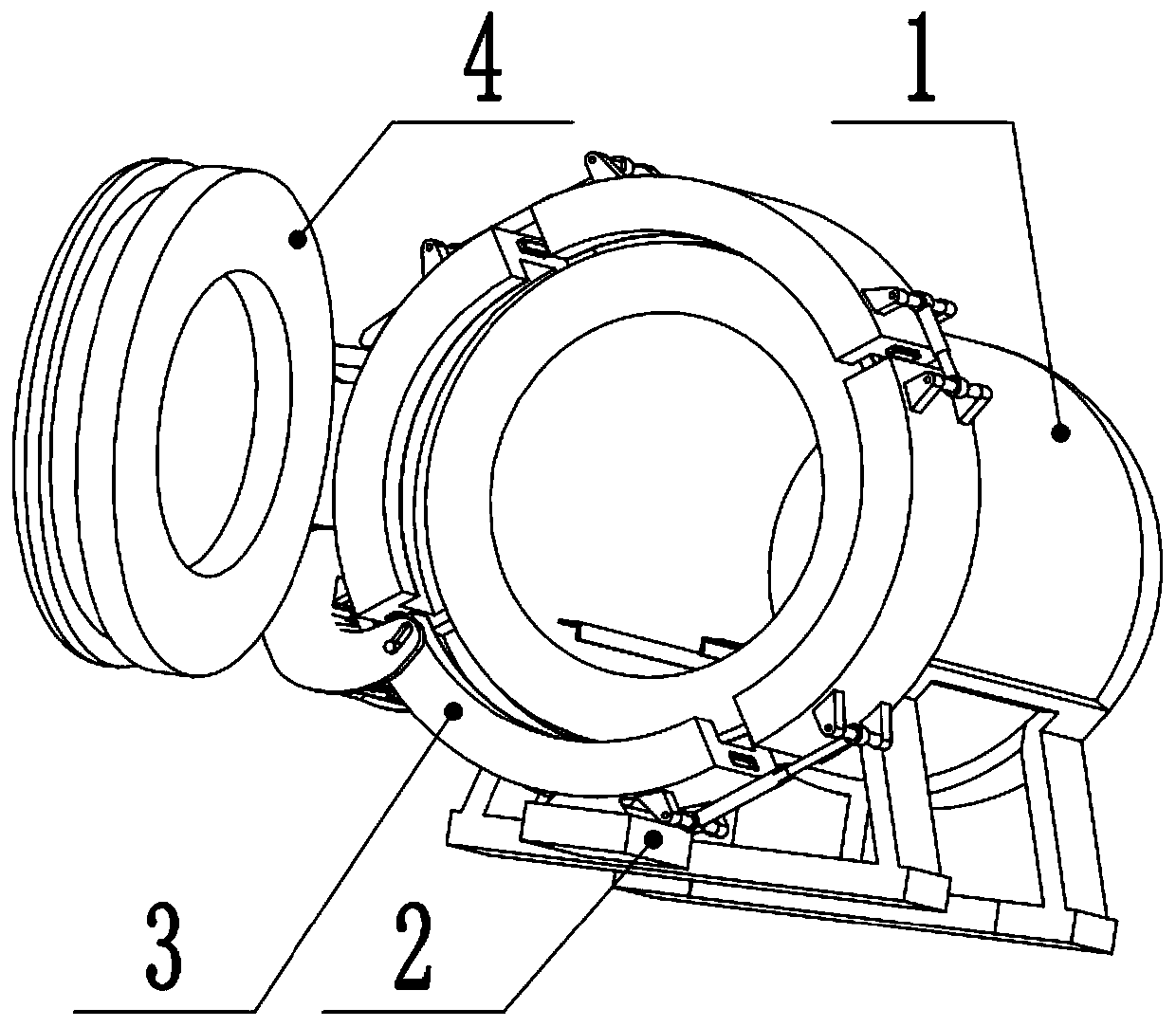

[0040] Refer to attached image 3 , attached figure 1 And attached Figure 10 , start the automatic control closure process:

[0041] 1) The hydraulic push-pull rod C (50) of the link mechanism (43) in the end cover opening and closing assembly (4) starts to work, and the link mechanism (43) drives the end cover ( 41) Close to the kettle body locking end (11) of the kettle body assembly (1), the end cover locking end (61) of the end cover (41) and the kettle body locking end (11) of the kettle body assembly (1) align.

[0042] 2) Then a pair of hydraulic push-pull rods A (36) of the clamp assembly (3) start to tighten the work, so that the combined clamp A (31) and clamp B (32) components move downward, and the clamp groove The shape and the aligned end cover locking end (61) and the kettle body locking end (11) are matched and approached, and because the aligned end cover locking end (61) and the kettle body locking end (...

Embodiment 2

[0046] Embodiment 2 Kettle body opening process

[0047] Refer to attached figure 1 , attached image 3 , attached Figure 10 And attached Figure 11 , start the automatic control opening process:

[0048] 1) The hydraulic push-pull rod B (37) on the assembly of clamp A (31) and clamp B (32) and the assembly of clamp C (33) and clamp D (34) starts to be pushed apart at the same time, when clamp A ( The distance between 31) and clamp B (32) and between clamp C (33) and clamp D (34) can ensure that the hydraulic push-pull rod B (37) stops working when the end cover (41) can be opened smoothly in this direction ; In this process, the support lifting guide block (22) in the support assembly (2) descends earlier than the clip C (33), ensuring that the clip assembly (3) can move freely.

[0049] 2) Then, since the assembly of clamp C (33) and clamp D (34) is only affected by the pulling force of the hydraulic push-pull rod A (36), when the pair of hydraulic push-pull rods A (36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com