Circulating conveying structure

A circulating conveying and chain technology, applied in conveyors, transportation and packaging, etc., can solve the problems of short conveying stroke and insufficient conveying power of thick chains, and achieve the effect of continuous and stable chain operation, avoiding direct contact and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

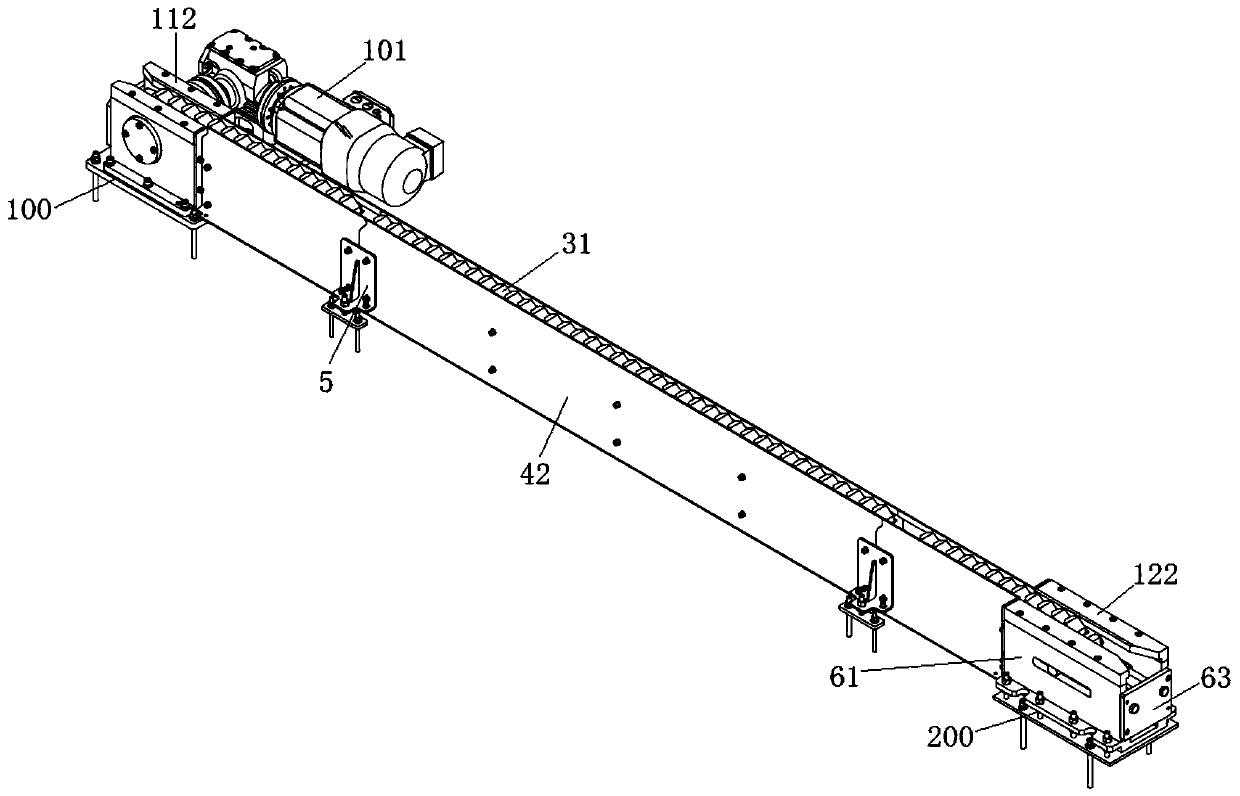

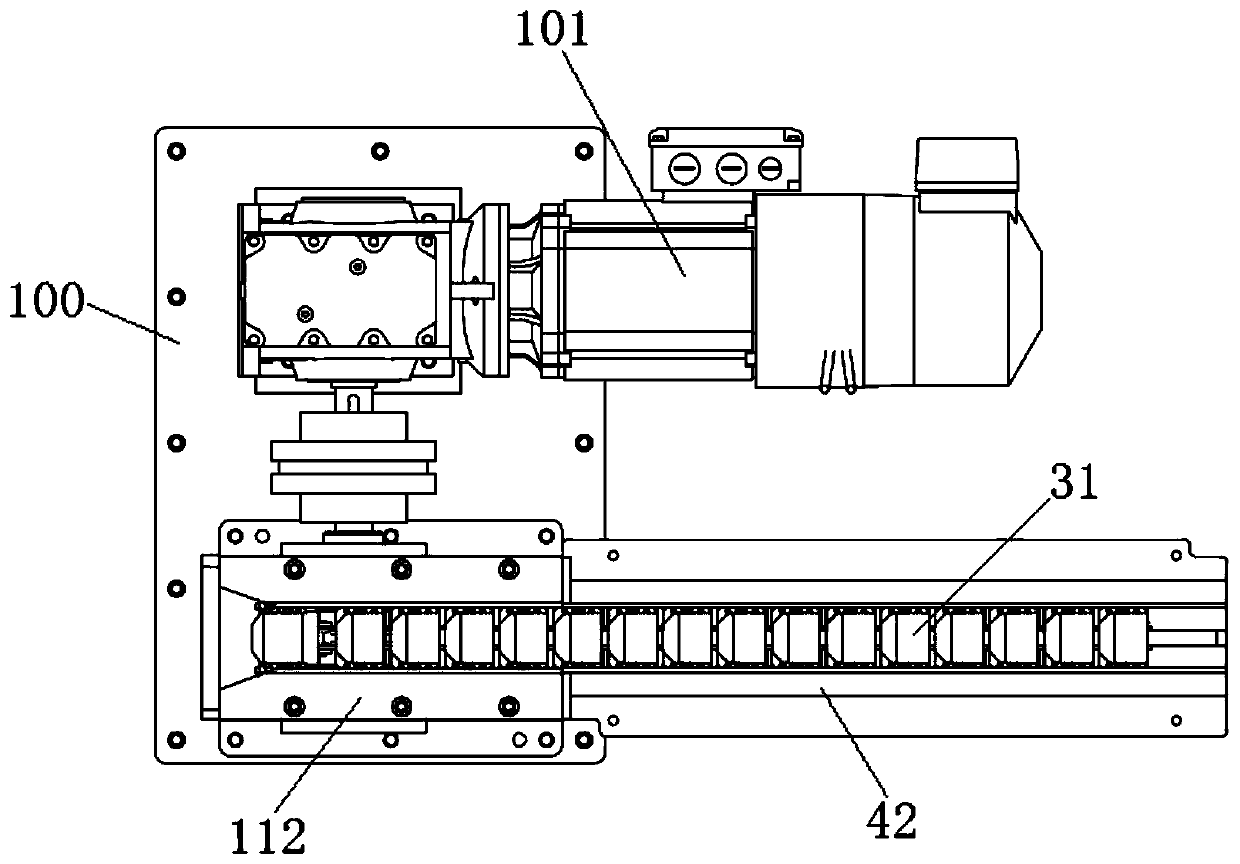

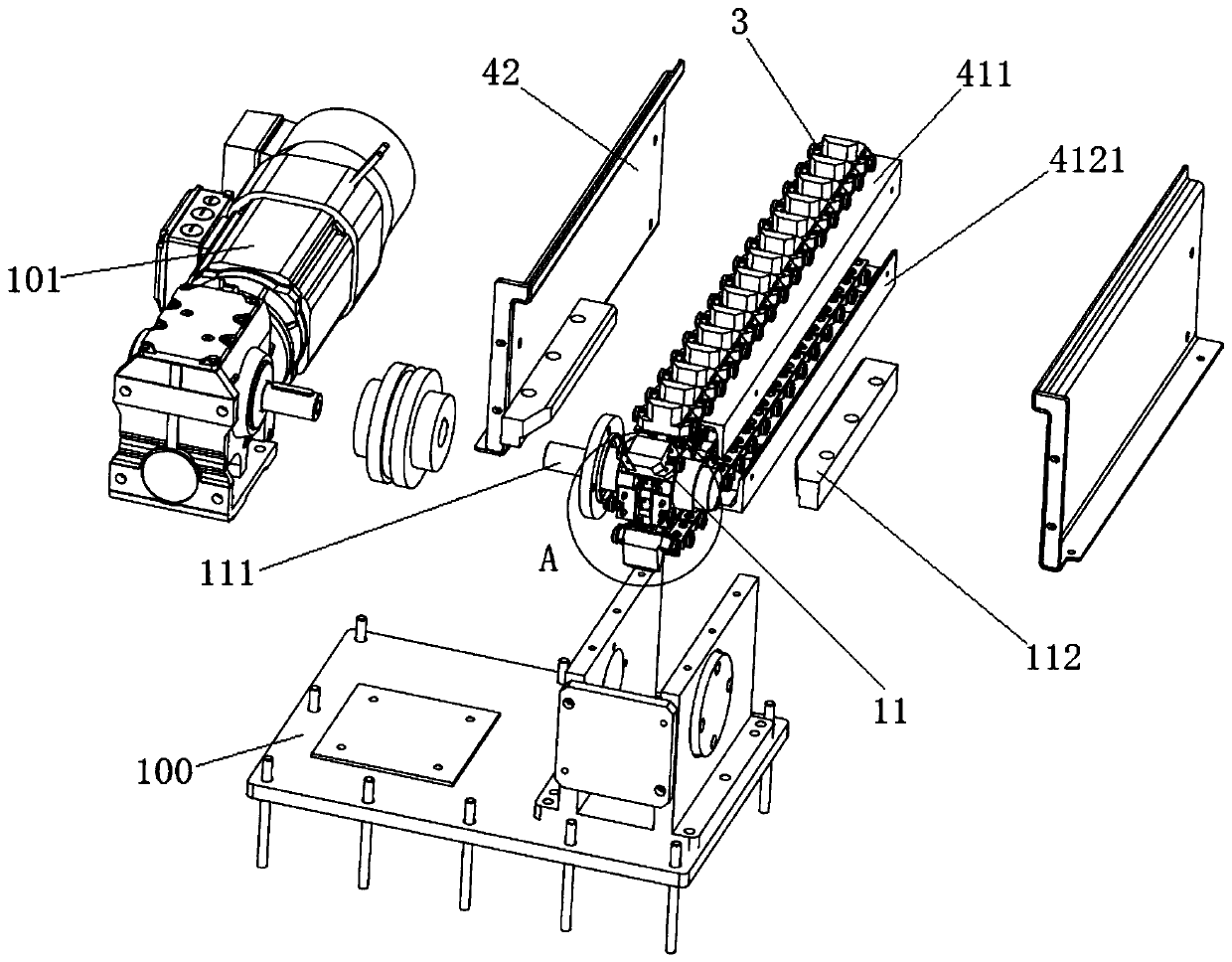

[0063] This embodiment provides a circular conveying structure, such as figure 1 As shown, it includes a sprocket, a chain 2 , several carrying components 3 and a support component 4 , the sprocket includes a driving wheel 11 and a driven wheel 12 , and the chain 2 is tightly wound around the driving wheel 11 and the driven wheel 12 . Such as figure 2 and image 3 As shown, the driver 101 is installed on the first mounting base 100, the drive shaft of the driver 101 is connected with the driving shaft 111 of the driving wheel 11, the driver 101 is suitable for driving the driving wheel 11 to rotate around the axis, and the second wheel located on both sides of the driving wheel 11 A mounting base 100 is vertically provided with fixing plates, and the driving shaft 111 is passed through and rotated on the fixing plates on both sides to realize the positioning of the driving wheel 11. In this embodiment, the driver 101 adopts a motor.

[0064] Such as Figure 5 and Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com