General rail shifting device for petroleum drilling machine

A transfer device and track-type technology, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems that different track-type transfer devices cannot be used universally, and achieve universality, optimization of limit devices, limit bit device for simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

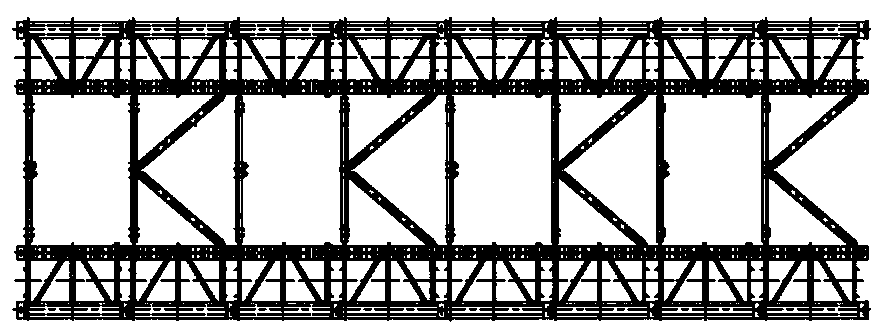

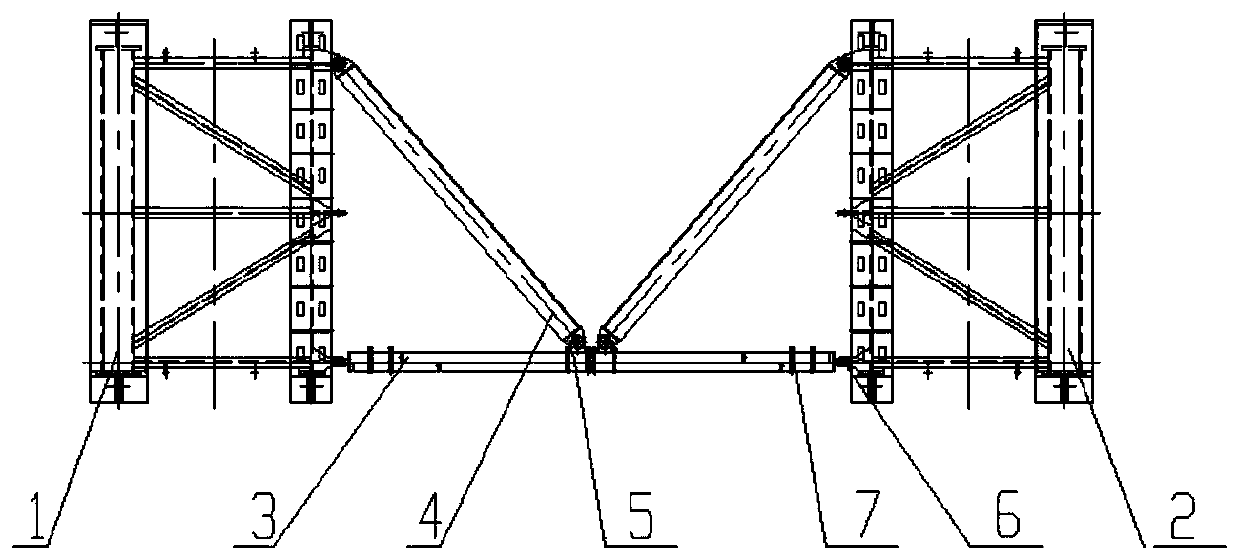

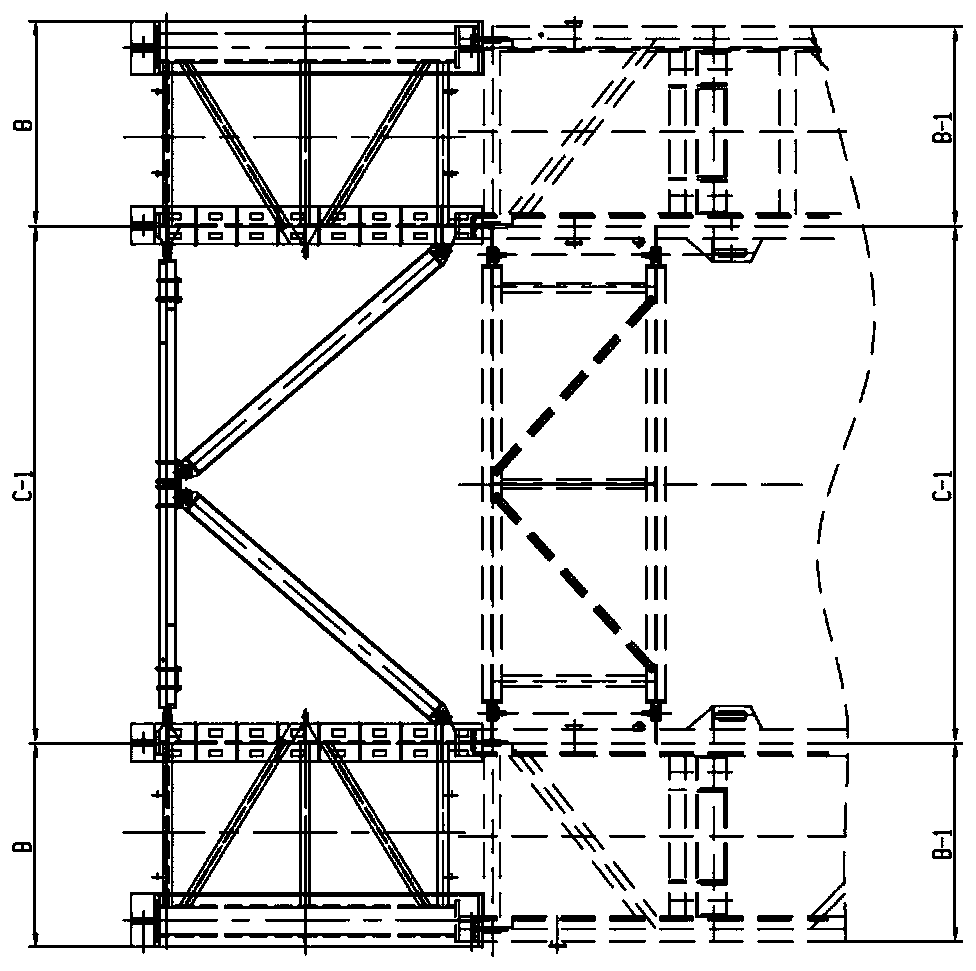

[0028] Such as Figure 1-8 As shown, the universal rail-type transfer device for oil drilling rigs of the present invention is characterized in that it includes a group of transfer units sequentially connected by connecting pins 6, and each transfer unit includes a film rack I1 and a film rack arranged on both sides. II2, connecting the combined beam 3 and inclined beam 4 of the two sides of the film rack I1 and the film rack II2, the two ends of the combined beam 3 are respectively connected to the film rack I1 and the film rack II2 through the connecting pins 6 Connection, the combined beam 3 and the inclined beam 4 are connected through the ear seat 5 of the inclined beam.

[0029] The set of transfer units includes 6-10 transfer units.

[0030] The combined beam 3 includes a group of beams, and a beam card 7 connecting every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com