Bin wall discharging system of aluminum oxide storage bin

A discharge system, alumina technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of inability to achieve the conveying effect, uneven material conveying, unsteady feeding, etc., to solve the uncertainty of discharge , Uniform discharge, simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention will be described in further detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the invention and are not intended to limit the scope of the present invention.

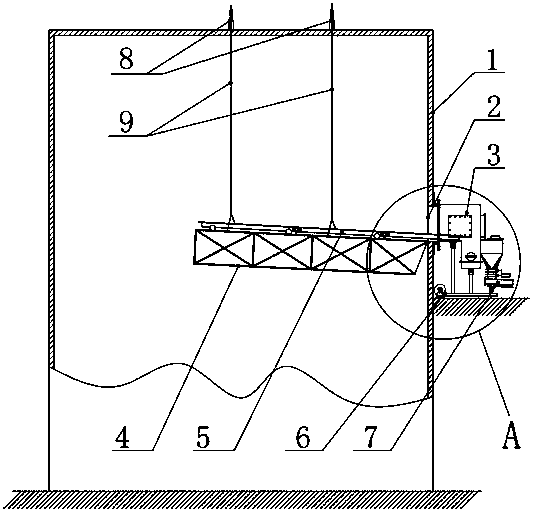

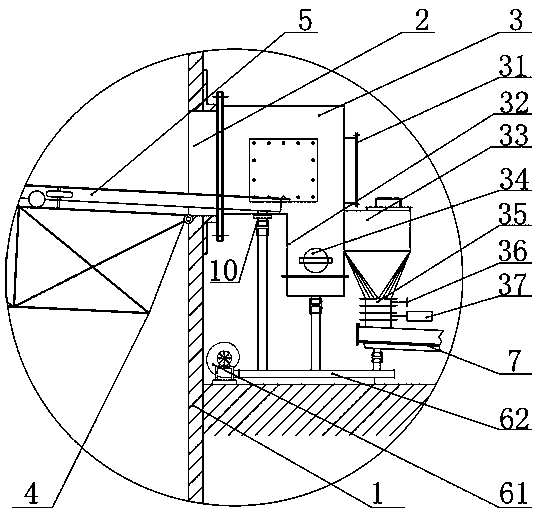

[0019] Such as figure 1 , figure 2 An alumina storage bin wall discharge system according to the present invention includes a storage bin 1 for storing alumina and a discharge port 2 set on the side wall of the storage bin 1, and also includes a sand removal filter device 3 and a steel frame 4 , open chute 5, pneumatic chute 7, air supply system 6; the left side of the top of the sand removal filter device 3 is connected to the discharge port 2 by a flange; a discharge port 35 is provided at the bottom of the sand removal filter device 3 , there is a slag discharge port 34 on the side; a manual flapper valve 36 and a pneumatic flapper valve 37 are arranged in turn at the discharge port 35, the manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com