Geotextile tube with inner cores and mud dehydration method combining geotextile tube with vacuum

A geotechnical tube bag, inner core technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of poor dehydration effect of geotechnical tube bags, difficult dehydration and solidification of mud, etc. The effect of drainage path, speeding up drainage and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

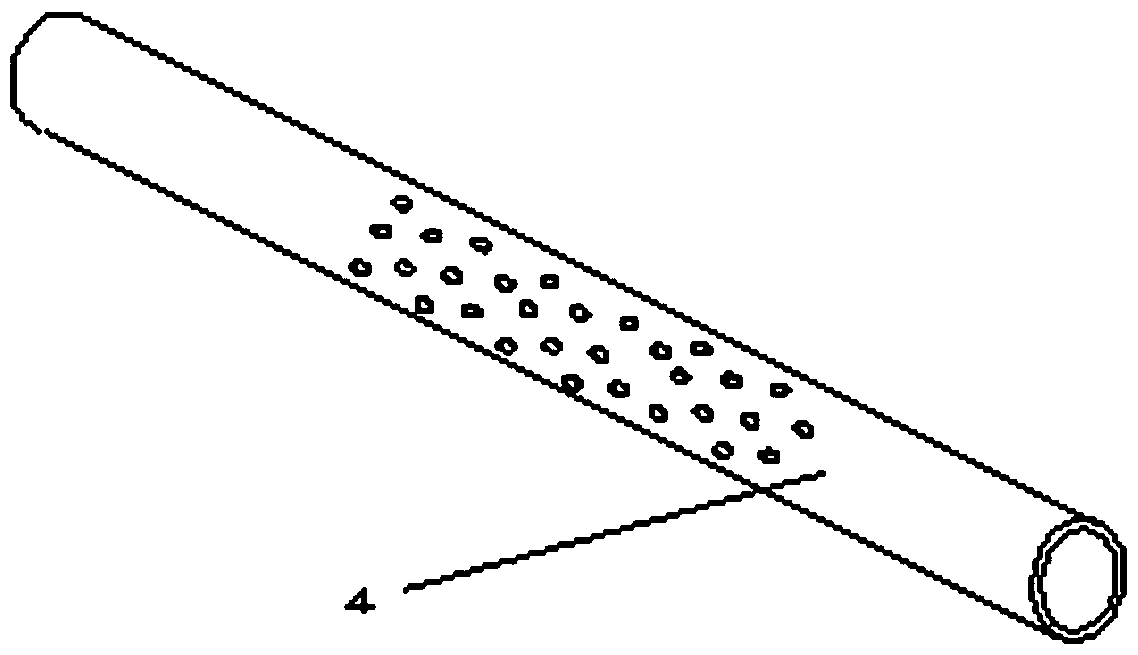

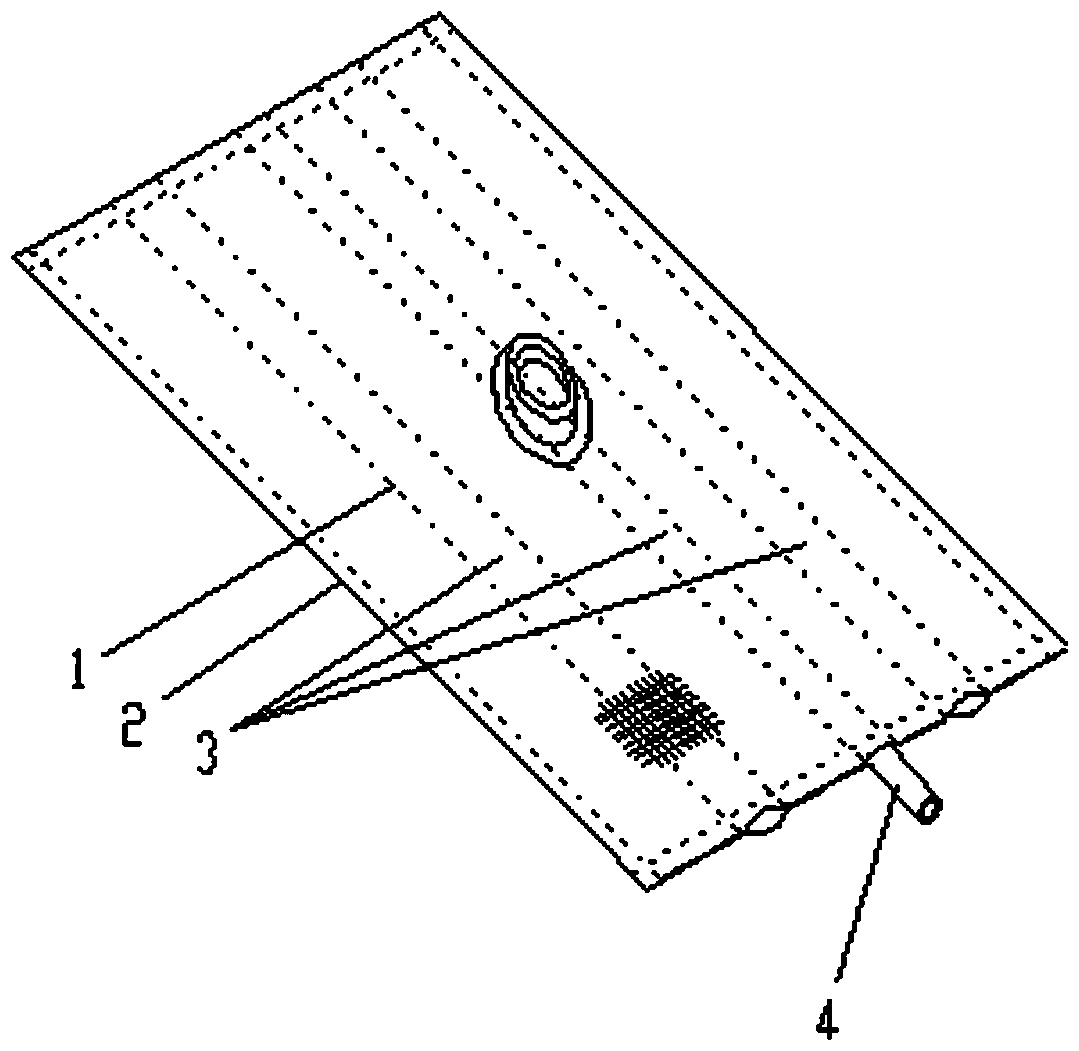

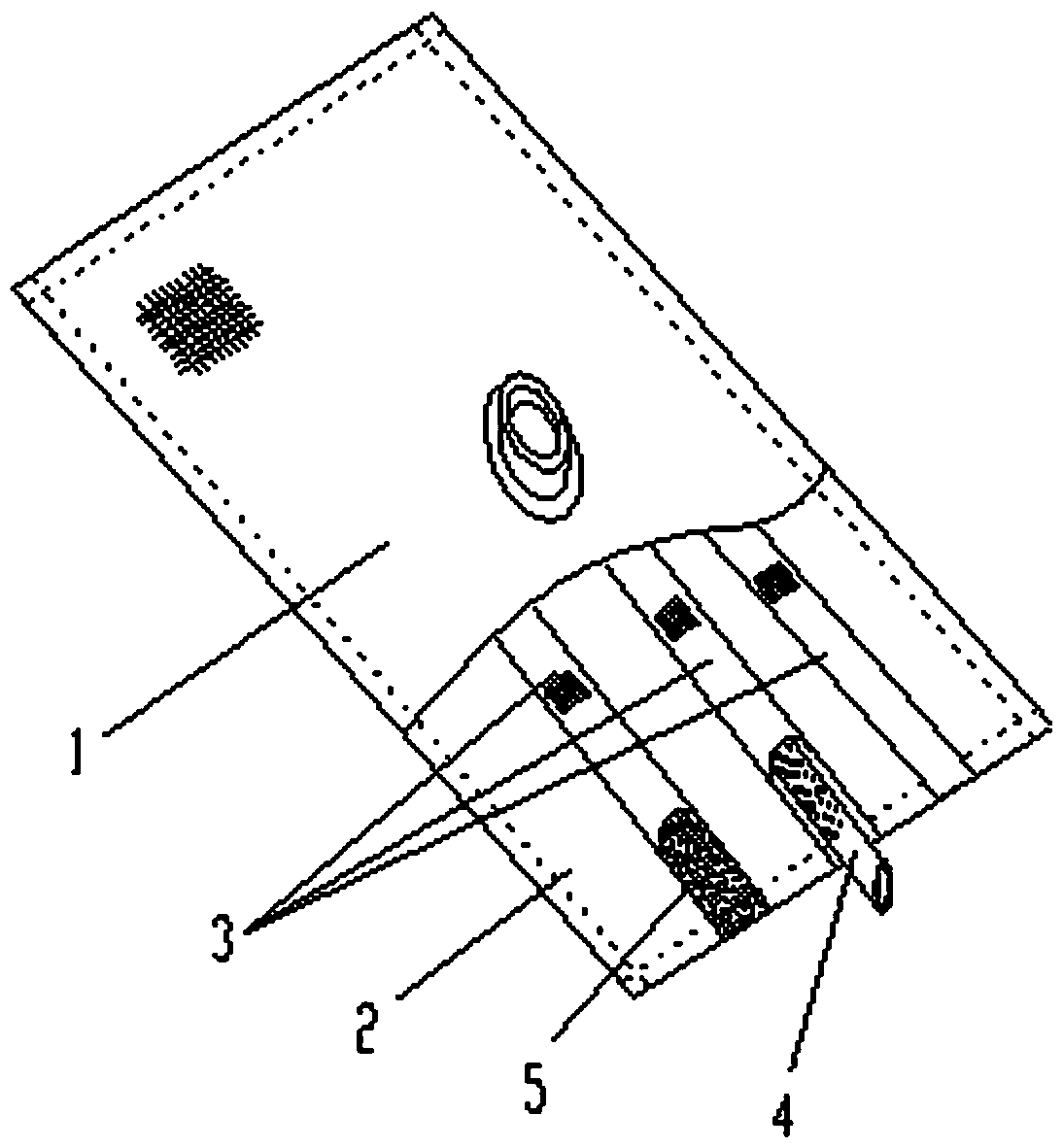

[0024] like figure 1 As shown in -6, the present invention includes a top cloth 1, a bottom cloth 2, several inner cores 3, a filter tube 4, medium sand or coarse sand 5. The top cloth 1 is polygonal, and the top cloth is provided with a grouting interface 101 . The base cloth 2 is polygonal, and the size and shape of the base cloth 2 and the top cloth 1 are the same. Several inner cores 3 are arranged in the geotechnical tube bag, and the inner cores 3 are arranged between the top cloth 1 and the bottom cloth 2, and the inner cores 3 are processed into a tubular or sleeve-shaped structure using the same geotextile as the top cloth and the bottom cloth. The filter pipe 4 is a round pipe with drainage holes drilled on the periphery, and the round pipe is a metal pipe or a hard plastic pipe.

[0025] In the present invention, the top fabric 1 is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com