Viscosity index improver and preparation method thereof

A viscosity index improvement, viscosity index technology, applied in the field of viscosity index improver and its preparation, can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

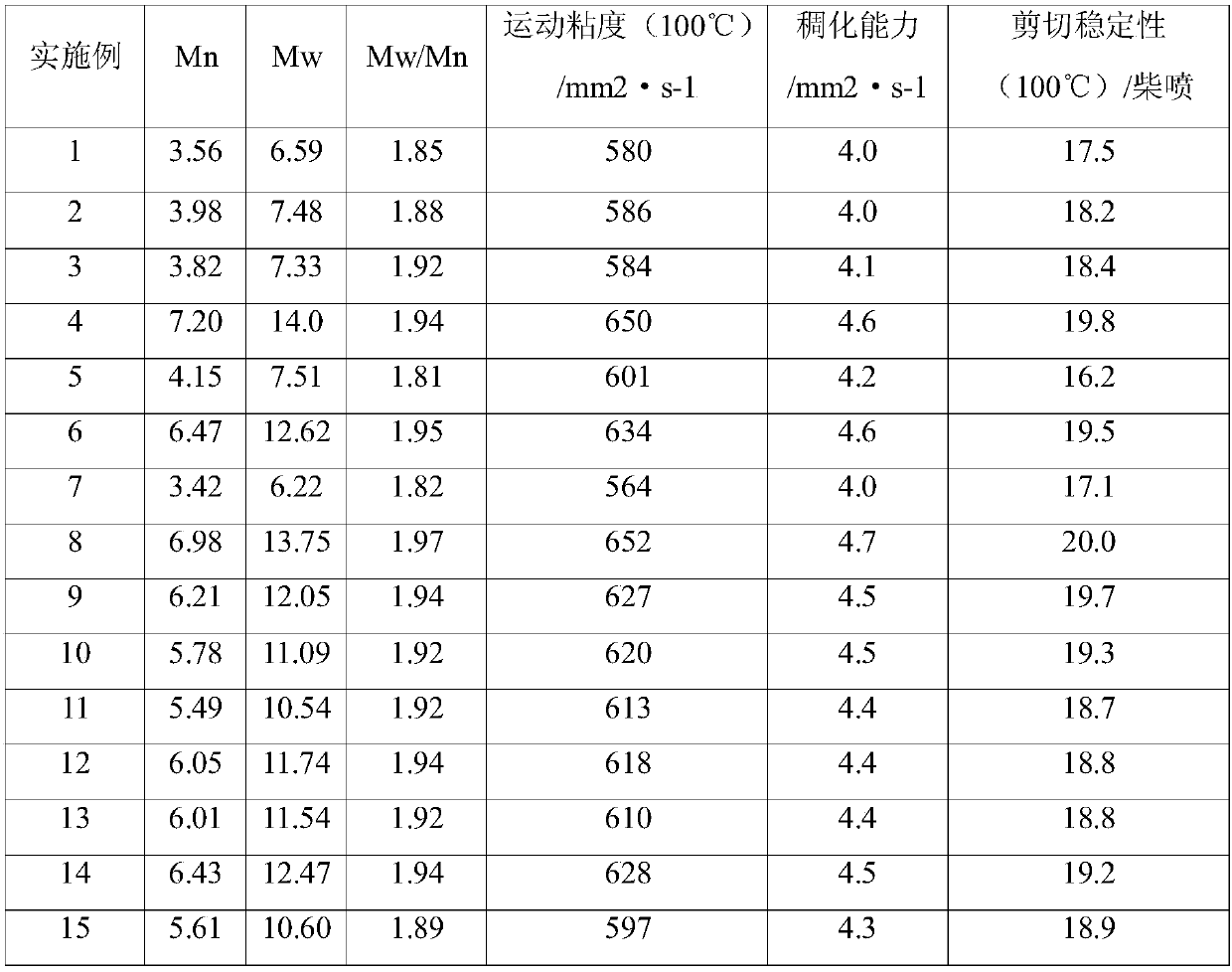

Examples

preparation example Construction

[0024] It can be seen from the background art that there is an urgent need to provide an ethylene-propylene rubber lubricating oil viscosity index improver with high thickening ability and low shear stability index in the prior art. The inventors of the present invention have conducted research on the above-mentioned problems and provided a preparation method of a viscosity index improver, which includes the following steps: S1, mixing a graft initiator, an acrylic compound, an ethylene-propylene rubber polymer and a solvent and performing grafting Branching reaction to obtain the first solution of ethylene-propylene copolymer grafted with acrylic compound; S2, mixing the first solution with amine compound and performing amination reaction to obtain a viscosity index improver.

[0025] The low-temperature stability, high-temperature thickening ability, and shear stability of the ethylene-propylene copolymer viscosity index improver product obtained by the above-mentioned prepar...

Embodiment 1

[0041] The initial temperature of ethylene-propylene polymer hexane solution in the present embodiment is between 15~25 ℃, and solid content is 4.0%, and the content of the molecular chain unit corresponding to ethylene is 48.5%, polymer Mooney viscosity (ML 1+4 100 ° C) was 6.0, the number average molecular weight of the polymer was 79,000, the weight average molecular weight was 158,000, and the relative molecular mass distribution was 2.00.

[0042] Get above-mentioned polymer hexane solution 0.6L and add in the reactor, add benzoyl peroxide and acrylic acid, the weight of acrylic acid is 1.0% of ethylene propylene rubber polymer weight, the weight of benzoyl peroxide is ethylene propylene rubber polymer 2.0% by weight, the stirring speed is 125r / min, the internal temperature of the reactor is 80℃~82℃, the pressure of the reactor is 0.115MPa~0.120MPa, after 4 hours of reaction, stop stirring, and slowly open the gas phase outlet valve for flash operation , the discharged g...

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 is:

[0046] The solid content of the ethylene-propylene polymer hexane solution was 8.1%, and the solid content of the glue after flash evaporation was 12.0%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap