Method for the preparation of ethanol

A technology of ethanol and saccharification, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of cell metabolism, yeast cell toxicity, unevenness, etc., to improve economic benefits, high ethanol concentration, increase yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

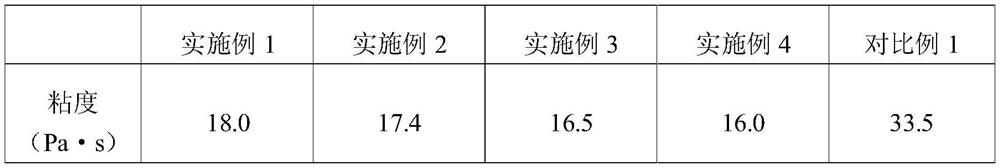

[0024] According to the background, it is known that in the prior art, there is an urgent need to develop a concentrated alcohol fermentation technique, so that it can achieve both high concentration of ethanol fermentation, and can ensure that the viscosity of the liquid meets the mixing, delivery, and heating the cooling process. The inventors of the present invention conducted a method of studying ethanol, including the step of: step S1, liquidified and glycated to obtain a saccharified fluid; step S2, step S2 The concentration of glucose in the syrup supernatant and the syrup supernatant is greater than the concentration of glucose in the saccharified liquid; the remaining saccharified liquid is blended with the syrup supernatant to obtain ethanol.

[0025] In the above-described preparation method of the present invention, since it is blended with a syrup supernatant having a solid content and a saccharified liquid, it is possible to greatly reduce the viscosity of the fermen...

Embodiment 1

[0048] The method of preparing ethanol according to the present embodiment includes the steps of:

[0049] After pulverizing corn grain size ≤ 3mm, a starch slurry having a dry mass concentration of 26% was prepared.

[0050] The dry mass concentration was 26% of the starch slurry, and the liquefaction of 55u / g was added. The liquefaction temperature was 1.4 h at 1.4 h, which was placed, liquefied, and liquefied, and then fell to 56 ° C, the volume fraction was 0.05%, 72% dilute sulfuric acid, pH adjusted to 4.0 to 4.5, and then adding 235 u / g of glycogenase, glycified 3.0 h, prepared a high sugar concentration of saccharified liquid, prepared gum The glucose concentration was 221 g / L, and the prepared partial saccharified liquid was separated from the centrifugal apparatus to obtain two parts of the saclate and the syrup supernatant, and the glucose concentration in the prepared syrup was 221 g / L.

[0051] When the yeast is activated, first empty the yeast activating can ...

Embodiment 2

[0053] The method of preparing ethanol according to the present embodiment includes the steps of:

[0054] After crushing the corn grain size ≤ 3mm, a starch slurry having a dry mass concentration of 30% was prepared.

[0055] The dry matter mass concentration was 30% of the starch slurry, and the liquefaction of 63u / g was added, the liquefied temperature was 1.8 h, which was 1.8 h, which caused the starch pulverized, liquefied, and became liquefied. ° C, and 72% dilute sulfuric acid having a volume fraction of 0.05%, pH adjusted to 4.0 to 4.5, then add 255 u / g of sugar enzyme, saccharification 2.4 h, prepared a high sugar concentration of saccharified liquid, prepared gum The glucose concentration was 255 g / L, and the preparative partially saccharified liquid was separated from the centrifugal apparatus to obtain a saccharification and the syrup supernatant, and the glucose concentration in the prepared syrup was 255 g / L.

[0056] When the yeast is activated, first empty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com