A Converter Production Process of Extremely Low Mn Steel

A production process and an extremely low technology, which are applied in the field of converter production technology of extremely low Mn steel, can solve problems such as the inability to meet the production requirements of extremely low Mn steel, and achieve the effects of improving the smelting rate, avoiding cost waste and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A converter production process for extremely low Mn steel, comprising the steps of:

[0045] Using molten iron and scrap steel as raw materials, carry out converter blowing, tap steel, and obtain extremely low Mn steel molten steel;

[0046] Controlling the raw material, wherein, controlling the temperature and chemical composition of the molten iron, controlling the scrap ratio and chemical composition of the scrap;

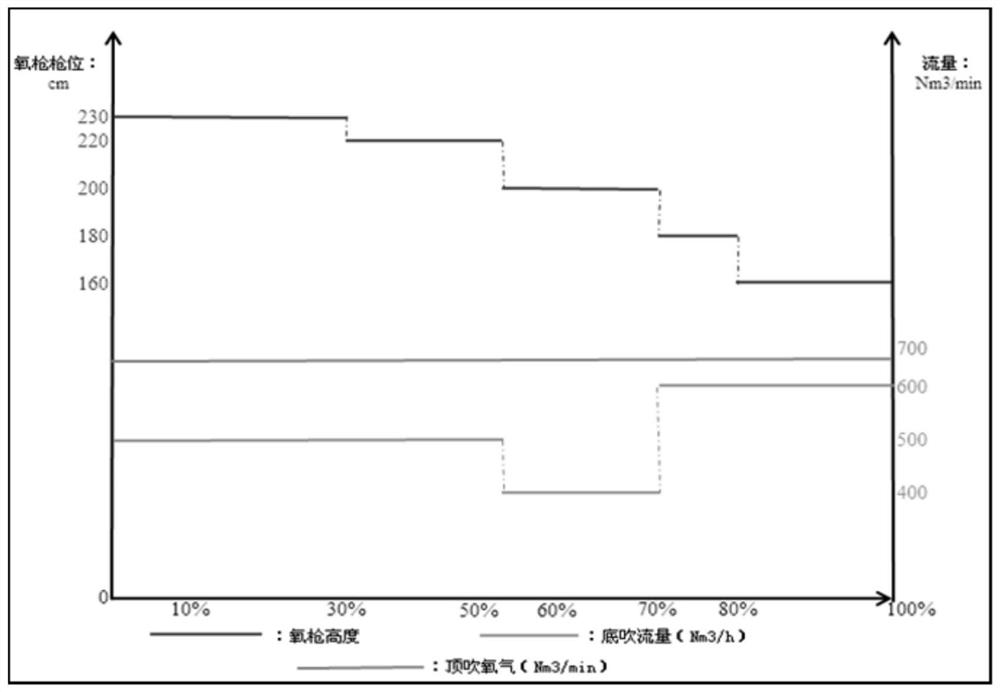

[0047] In the converter blowing process, the converter steelmaking and double slag operations are adopted with top-bottom combined blowing; the top-bottom combined blowing includes top-blown oxygen and bottom-blown inert gas, and the oxygen supply intensity of the top-blown oxygen is 700Nm 3 / min, in the bottom blowing inert gas, the gas supply intensity is 500Nm 3 / min;

[0048] At the end of the converter blowing, control the end temperature and the oxygen content of molten steel;

[0049] In the tapping, the amount of slag lowered during tapping is ...

Embodiment 2

[0059] A converter production process for extremely low Mn steel, comprising the steps of:

[0060]Using molten iron and scrap steel as raw materials, carry out converter blowing, tap steel, and obtain extremely low Mn steel molten steel;

[0061] Controlling the raw material, wherein, controlling the temperature and chemical composition of the molten iron, controlling the scrap ratio and chemical composition of the scrap;

[0062] In the converter blowing process, the converter steelmaking and double slag operations are adopted with top-bottom combined blowing; the top-bottom combined blowing includes top-blown oxygen and bottom-blown inert gas, and the oxygen supply intensity of the top-blown oxygen is 700Nm 3 / min, in the bottom blowing inert gas, the gas supply intensity is 400Nm 3 / min;

[0063] At the end of the converter blowing, control the end temperature and the oxygen content of molten steel;

[0064] In the tapping, the amount of slag removed from the tapping is...

Embodiment 3

[0074] A converter production process for extremely low Mn steel, comprising the steps of:

[0075] Using molten iron and scrap steel as raw materials, carry out converter blowing, tap steel, and obtain extremely low Mn steel molten steel;

[0076] Controlling the raw material, wherein, controlling the temperature and chemical composition of the molten iron, controlling the scrap ratio and chemical composition of the scrap;

[0077] In the converter blowing process, the converter steelmaking and double slag operations are adopted with top-bottom combined blowing; the top-bottom combined blowing includes top-blown oxygen and bottom-blown inert gas, and the oxygen supply intensity of the top-blown oxygen is 700Nm 3 / min, in the bottom blowing inert gas, the gas supply intensity is 600Nm 3 / min;

[0078] At the end of the converter blowing, control the end temperature and the oxygen content of molten steel;

[0079] In the tapping, the amount of slag removed from the tapping i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com