Multi-turning work platform and engineering vehicle

A technology for working platforms and installation platforms, applied in cranes, mechanically driven excavators/dredgers, etc., can solve problems such as the inability to achieve independent operation or collaborative operation, improve the level of automation and operation efficiency, and improve the adaptability to multiple working conditions. ability, the effect of improving the adaptability to working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

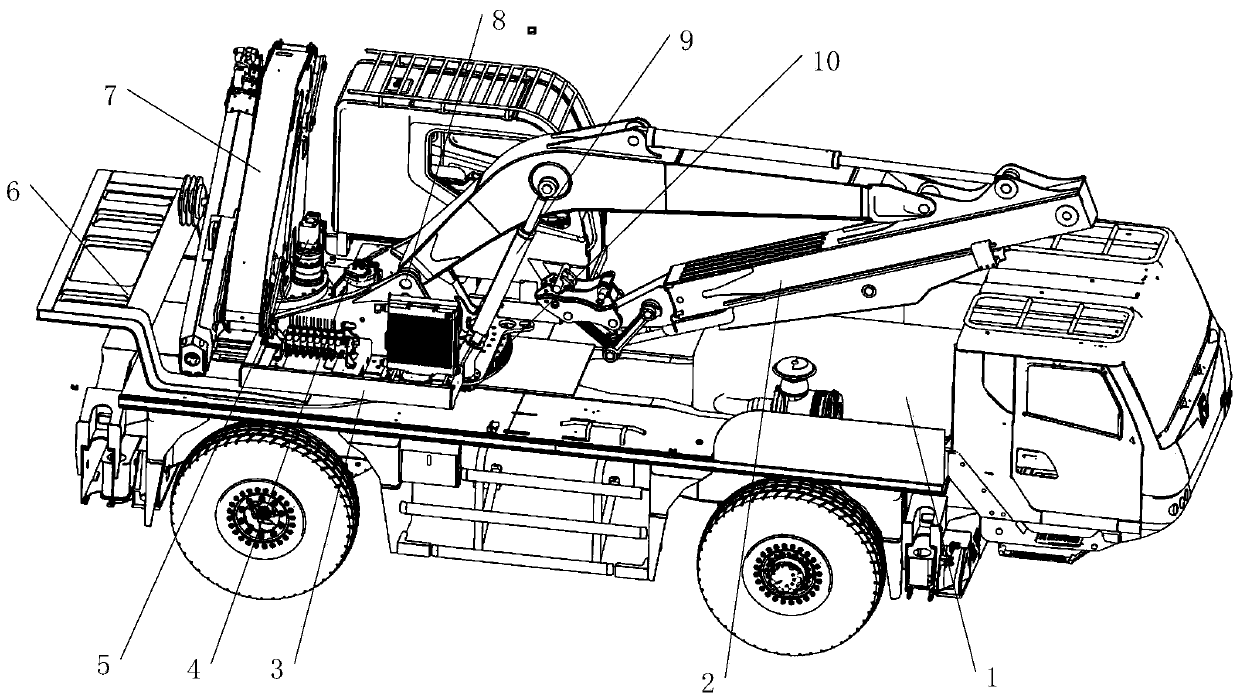

[0034] like figure 1 As shown, a multi-turn working platform of the present invention includes a first working device 2 , a working device installation platform 3 , a first slewing mechanism 4 , a second slewing mechanism 5 and a second working device 7 .

[0035] The working device installation platform 3 is rotatably connected with the chassis 1, which is fixed and supported together, through the first slewing mechanism 4; the first working device 2 is hinged to the front end of the working device installation platform 3 through the pin shaft 8; the second working device 7 is passed through the first The second slewing mechanism 5 is rotatably connected to the rear end of the working device installation platform 3 .

[0036] In other embodiments, the chassis 1 can also be other fixed supports that can perform the same fixing function.

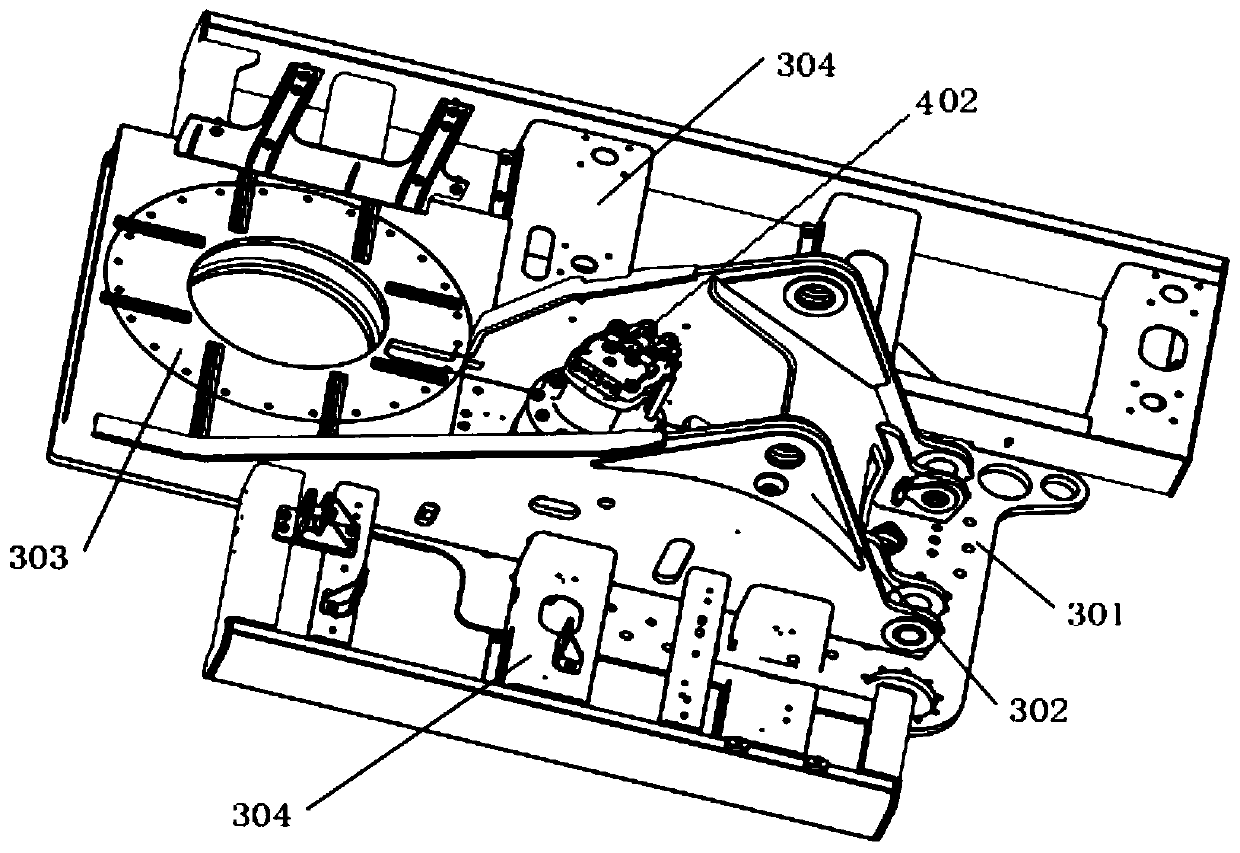

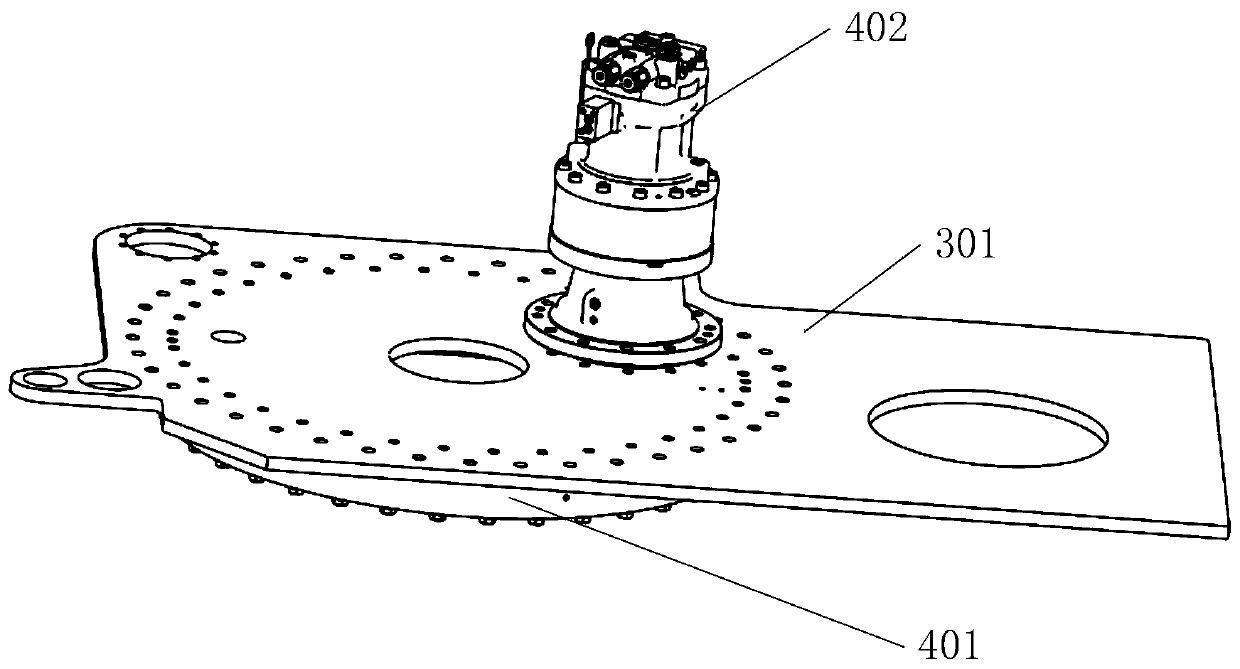

[0037] combine figure 2 , image 3 , Figure 4 and Figure 5 As shown, the working device installation platform 3 is welded by a botto...

Embodiment 2

[0051] like figure 1 , figure 2 and image 3 As shown, on the basis of Example 1, an engineering vehicle with a three-rotation work platform is designed. The working device installation platform 3 is connected to the chassis 1 of the construction vehicle through the first slewing mechanism 4 .

[0052] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com