Full-floating vibration-absorbing and sound-insulating floor and construction method thereof

A technology of vibration reduction and sound insulation and construction method, which is applied in the direction of construction, insulation layer, building structure, etc., and can solve the problems of increasing costs and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Example of construction method

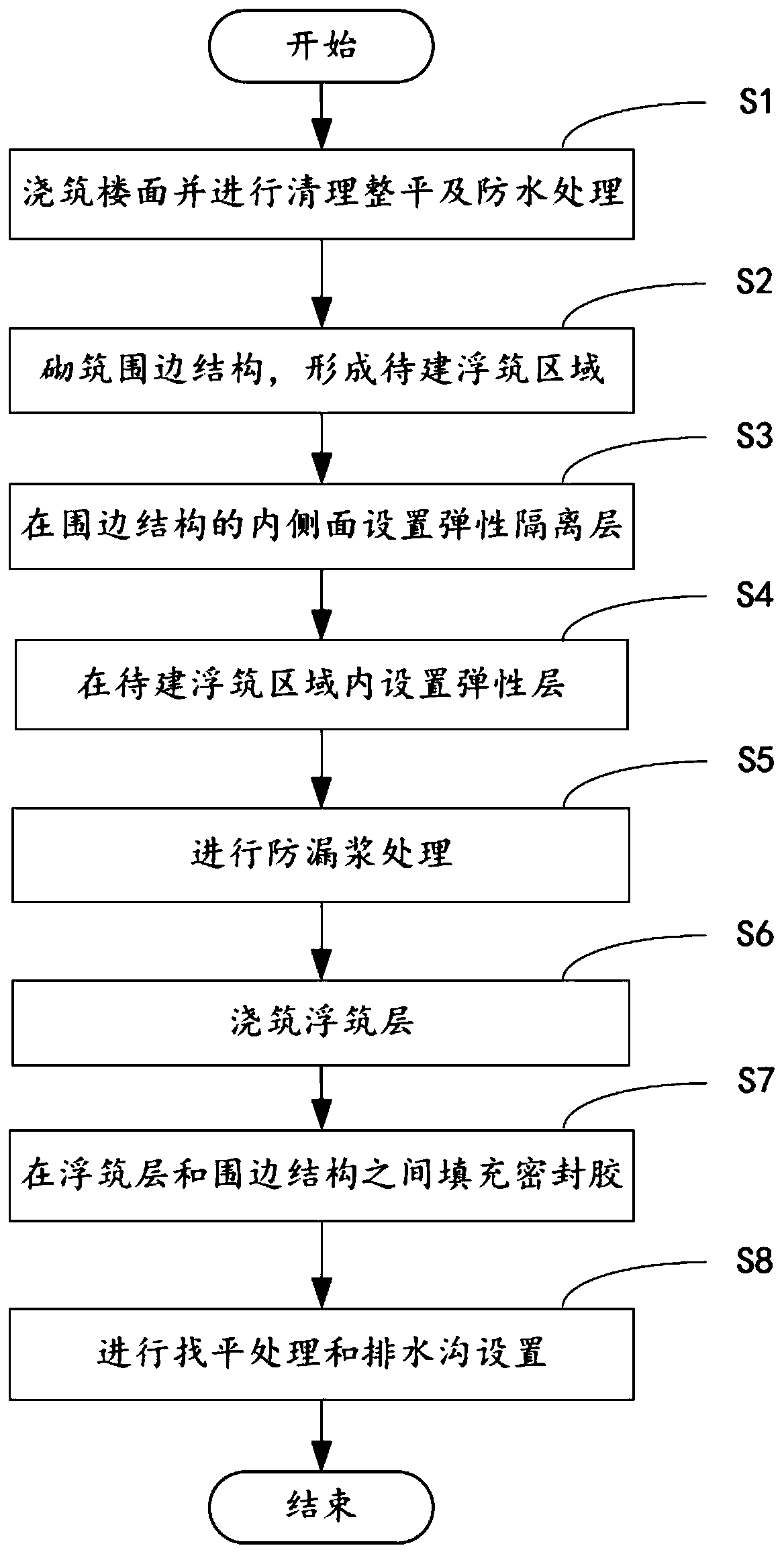

[0024] see figure 1 , figure 1 It is a flowchart of the construction method of the embodiment of the present invention. The construction method of the full-floating vibration-damping and sound-insulating floor includes the following steps:

[0025] In step S1, the floor is poured and cleaned, leveled and waterproofed. This floor can be formed by pouring concrete on a reinforced truss deck. The steel truss floor deck is a combined formwork in which the steel bars in the floor are processed into steel trusses in the factory, and the steel bar trusses and galvanized profiled steel plates are welded into one. During construction, the reinforced truss floor deck can be laid directly on the beams, and then simple reinforcement works and concrete pouring.

[0026] Specifically, before concrete is poured, all steel bars on the steel truss floor deck must be bound, and concrete can only be poured after the inspection is correct. When pourin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com