Reinforcing structure and method for damaged wood structure mortise-tenon joint

A technology for strengthening structures and wooden structures, which is applied in the direction of building structure, building maintenance, building types, etc., can solve the problems of hindering the wooden components around the nodes and destroying the effect of the facade, etc., to achieve convenient promotion, little impact on the appearance, and improve the force performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

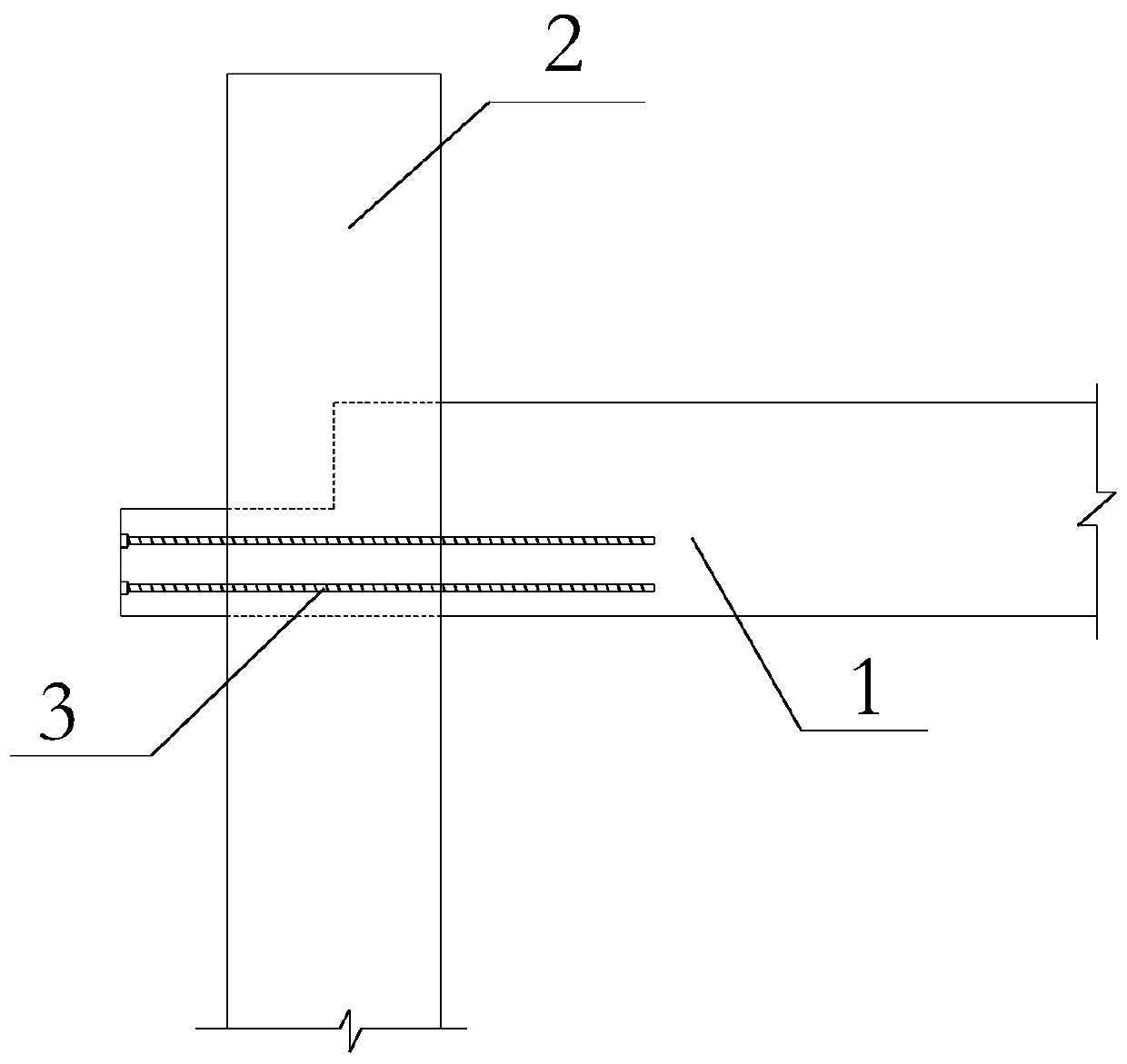

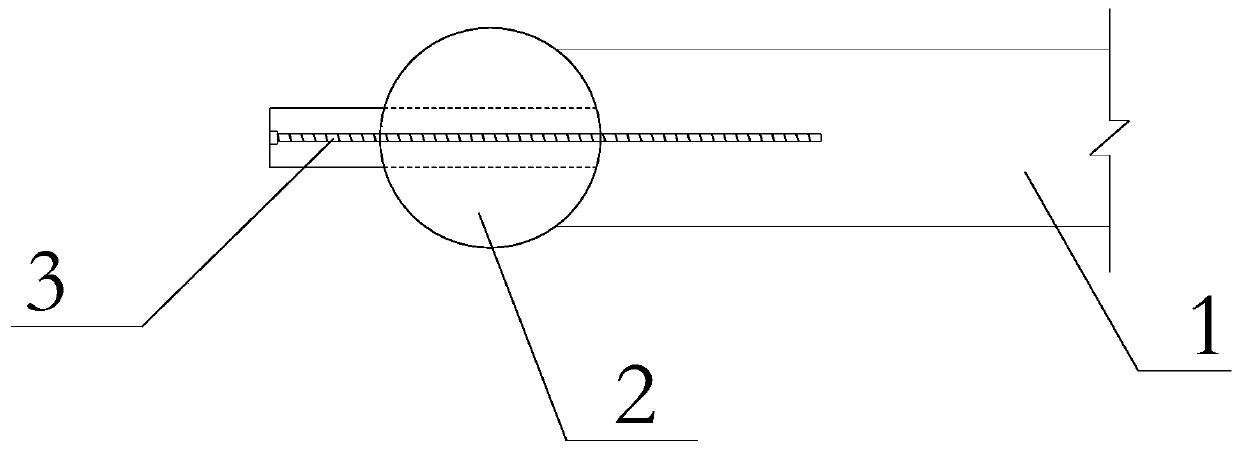

[0026] Such as Figure 1-Figure 2 As shown, a reinforced structure of damaged wooden structure mortise and tenon joints, including wooden columns 2, beams 1, the end of the beam 1 is the tenon head part, using a group of horizontally parallel self-tapping screws 3, self-mortise The end of the part is drilled inward into the beam 1, and the set of horizontally parallel self-tapping screws 3 is located in the same elevation.

[0027] In this example, see figure 1 , the tenon is L-shaped and stepped, and its outer end protrudes from the wooden post 2 . The tenon part is through tenon.

[0028] In this example, see figure 1 , the length of the self-tapping screw 3 extending into the beam 1 is not less than 1 times the diameter of the wooden column.

[0029] In this embodiment, when the width of the tenon is not greater than 50mm, the diameter of the self-tapping screw 3 is 6-8mm; when the width of the tenon is greater than 50mm, the diameter of the self-tapping screw 3 is 8-10...

Embodiment 2

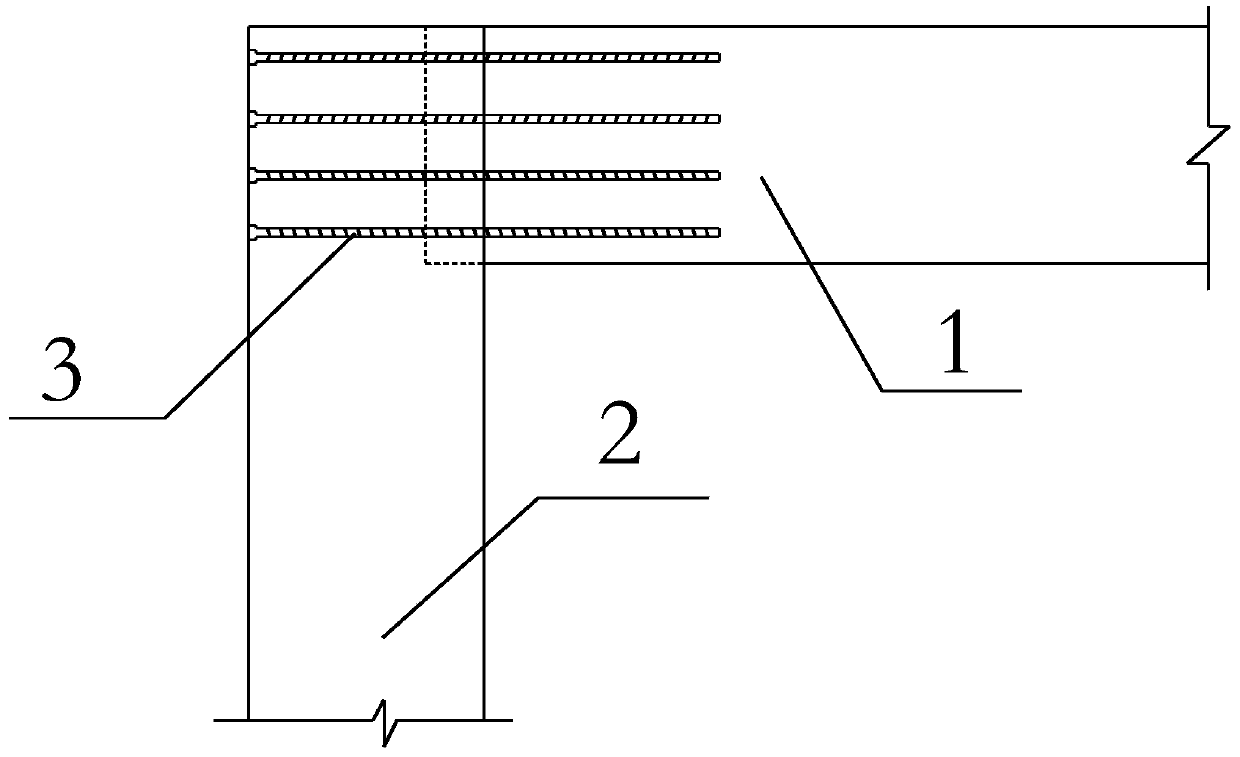

[0036] In this embodiment, the tenon is a dovetail tenon embedded in the wooden column 2, and a set of horizontally parallel self-tapping screws 3 start from the wooden column 2 and drill into the wooden column 2, the dovetail tenon and the wooden column 2 in sequence. Liang Fang1.

[0037] All the other are the same as embodiment one.

[0038] The invention provides a method for strengthening mortise and tenon joints of damaged wood structures, which can significantly improve the mechanical performance of mortise and tenon joints of damaged wood structures; and the method is simple and easy to implement, has little effect on the appearance of tenon and tenon joints, and is convenient for popularization .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com