Cylindrical roller bearing with integrated solid copper retainer

A cylindrical roller bearing and cage technology, which is used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of inability to meet the requirements of low noise of precision equipment, inability to ensure good lubrication of products, and unreasonable design structure. Good performance, easy processing, reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

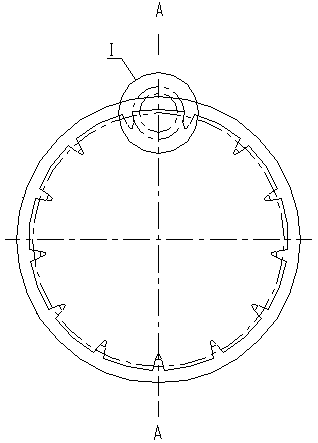

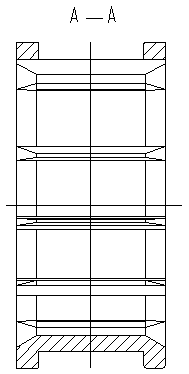

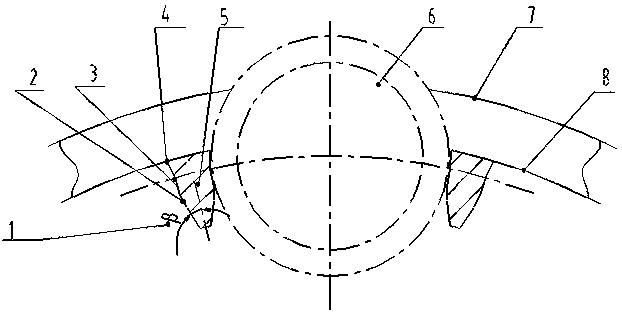

[0017] refer to Figure 1 to Figure 4 As shown, a cylindrical roller bearing with an integrated solid copper cage of the present invention includes an inner ring, an outer ring, a copper cage and rolling elements. The copper cage is composed of an inner edge 8, an outer edge 7 and several pocket beams 5. integrated structure. Wherein, the inner edge 8 and the outer edge 7 are connected by a pocket crossbeam 5, and the middle of the pocket crossbeam 5 both sides is a pocket wall 3, and its two sides are arc surfaces. The outer end of the pocket wall 3 is provided with an outer locking arc 4 , and the inner end is provided with an inner locking arc 2 . An inner lock entrance β angle 1 is arranged on the inner side of the arc amount 2 of the inner lock opening. The outer locking arc amount 4 of the pocket crossbeam 5, the inner locking arc amount 2 and the pocket wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com