Wire coil angle detecting device for high-voltage cable wire coil packaging

An angle detection, cable reel technology, applied in the direction of measuring devices, packaging, packaging protection, etc., can solve the problems of unstable rotation center position of the wire reel, affecting packaging accuracy, packaging position error, etc., to meet the accuracy requirements, eliminate The effect of transmission clearance and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

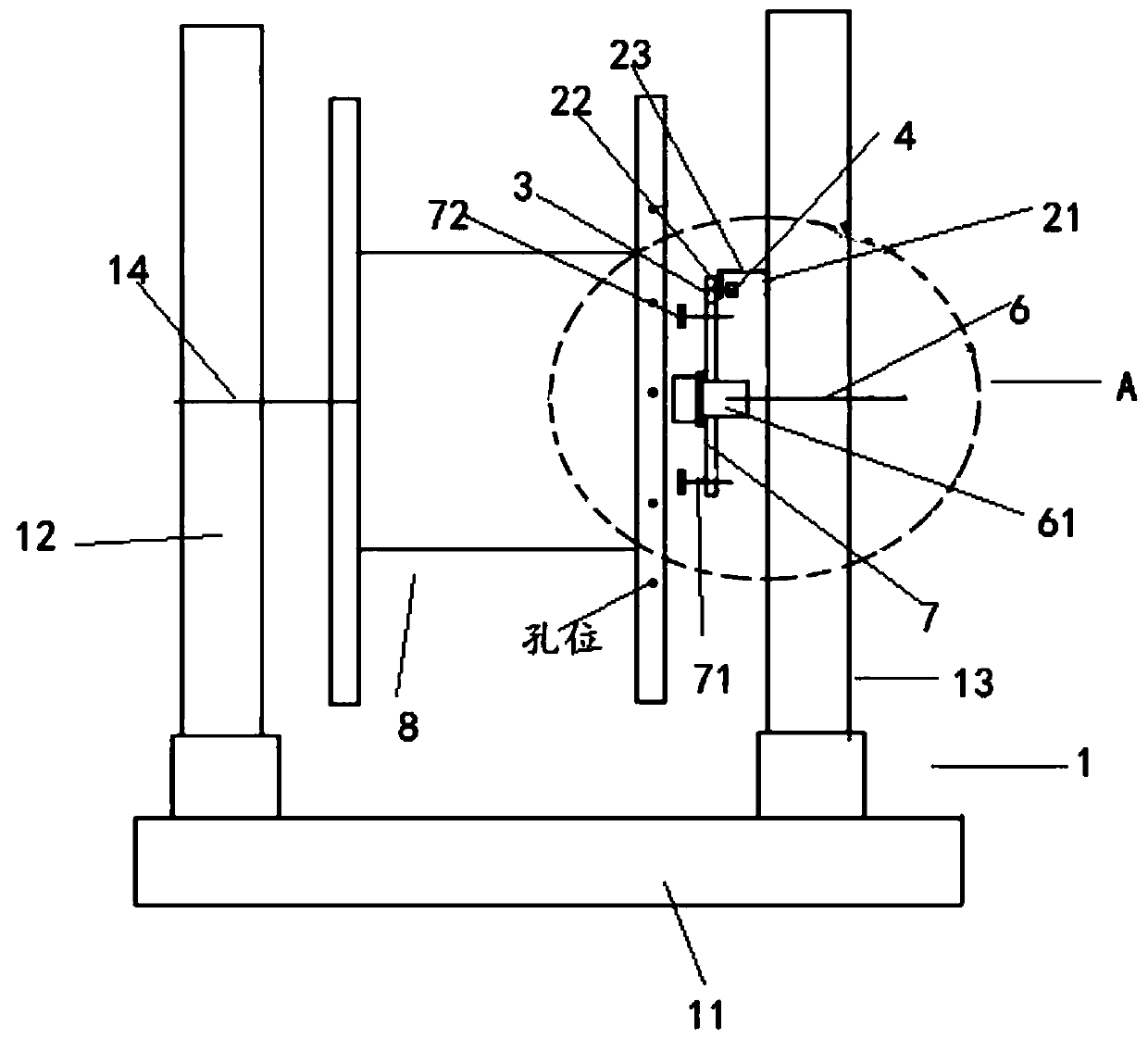

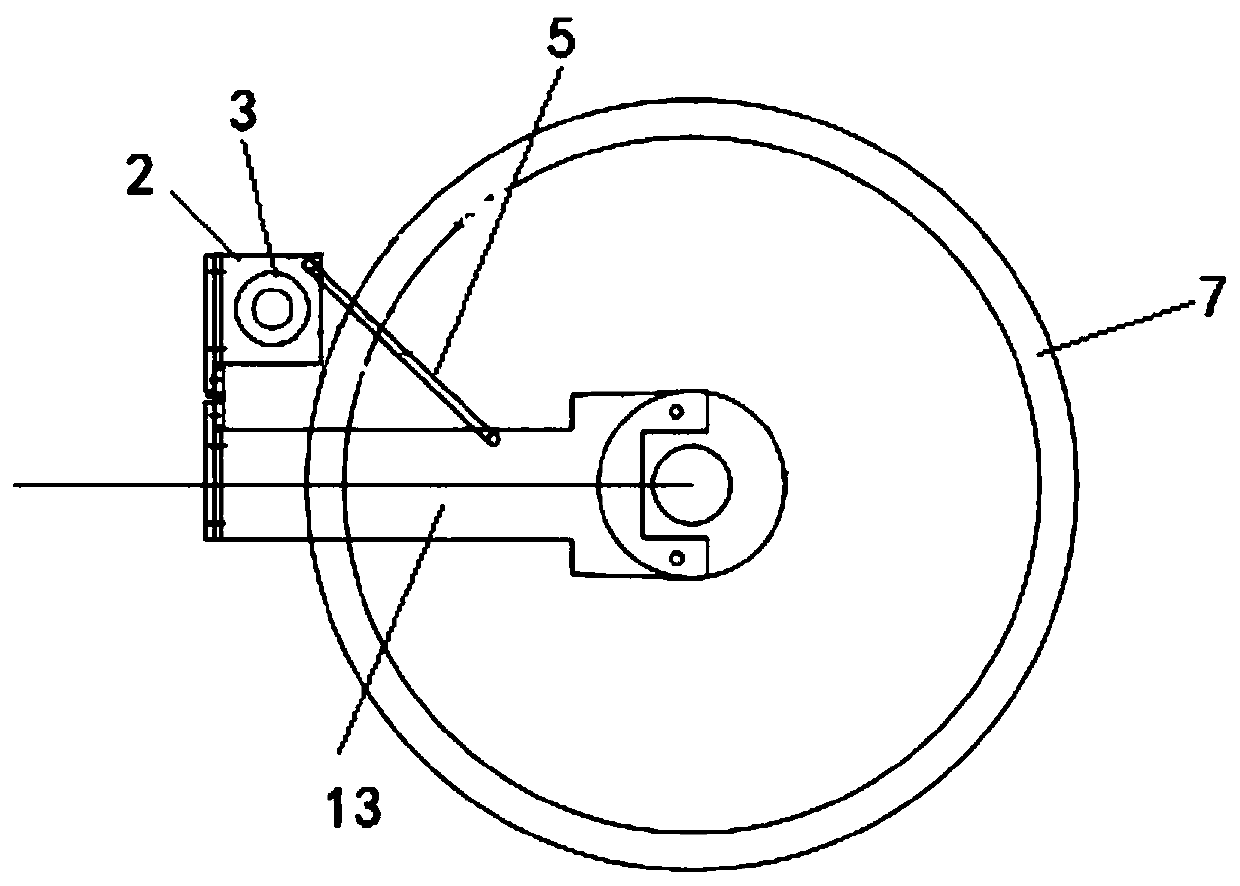

[0017] A coil angle detection device for high-voltage cable coil packaging, such as figure 1 and figure 2 As shown, the wire reel frame 1 is included, and the wire reel frame 1 includes a base 11 and two opposite first brackets 12 and second brackets 13 arranged on the base 11, wherein the side wall of the first bracket 12 is equipped with a first rotating shaft 14. The high-voltage cable reel is sleeved on the first rotating shaft 14, and the high-voltage cable reel 8 is driven to rotate through the first rotating shaft 14;

[0018] The second bracket 13 side wall tops are equipped with a fixed bracket 2 by a hinge, and the fixed bracket 2 includes two first fixed blocks 21 and the second fixed block 22 that are arranged oppositely, between the first fixed block 21 and the second fixed block 22 tops The connecting plate 23 is vertically connected and fixed, and the first fixed block 21 is mounted on the upper part of the side wall of the second support 13 by a hinge, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com