Temperature data processing method and device for test bearing of compressor

A data processing device, bearing temperature technology, applied in mechanical bearing testing, temperature measurement of moving solids, etc., to prevent misleading and paralysis, liberate manpower, and improve human-machine friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

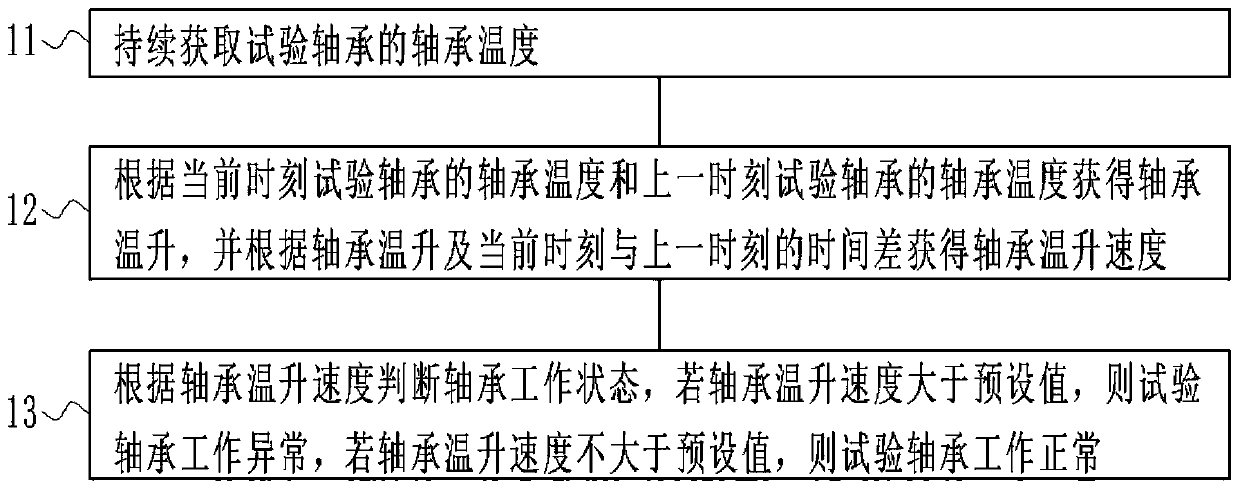

[0056] In order to solve the problems existing in the bearing temperature monitoring in the existing compressor test process, this application proposes a compressor test bearing temperature data processing method, which is mainly divided into three parts, such as figure 1 As shown, the first part includes the following:

[0057] Step 11: Continuously obtain the bearing temperature of the test bearing;

[0058] Step 12: Obtain the bearing temperature rise according to the bearing temperature of the test bearing at the current moment and the bearing temperature of the test bearing at the previous moment, and obtain the bearing temperature rise rate according to the bearing temperature rise and the time differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com